Patents

Literature

37results about How to "Realize cycle operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

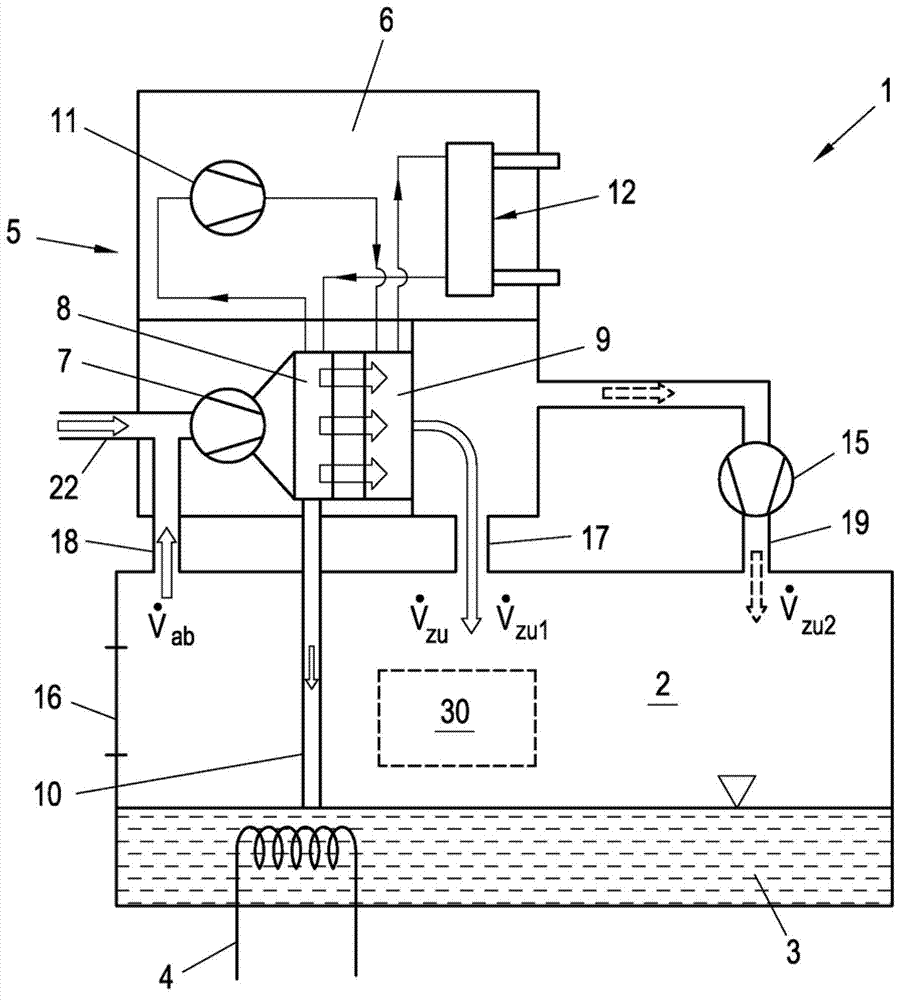

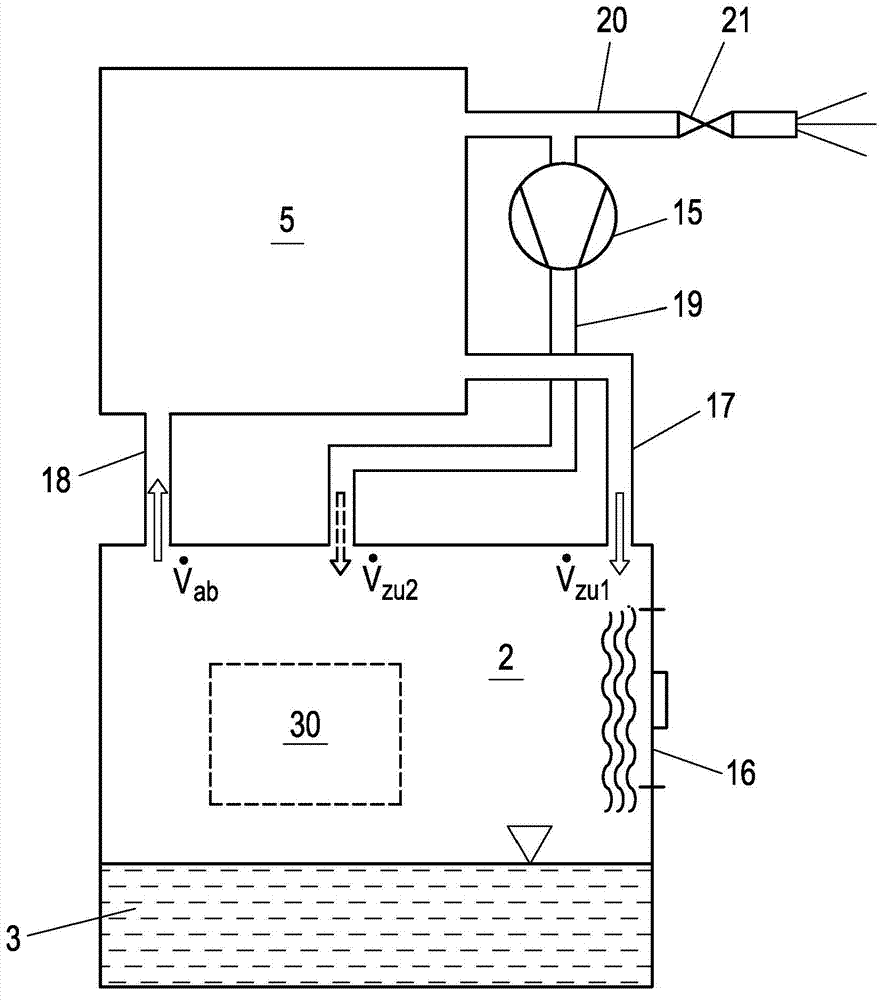

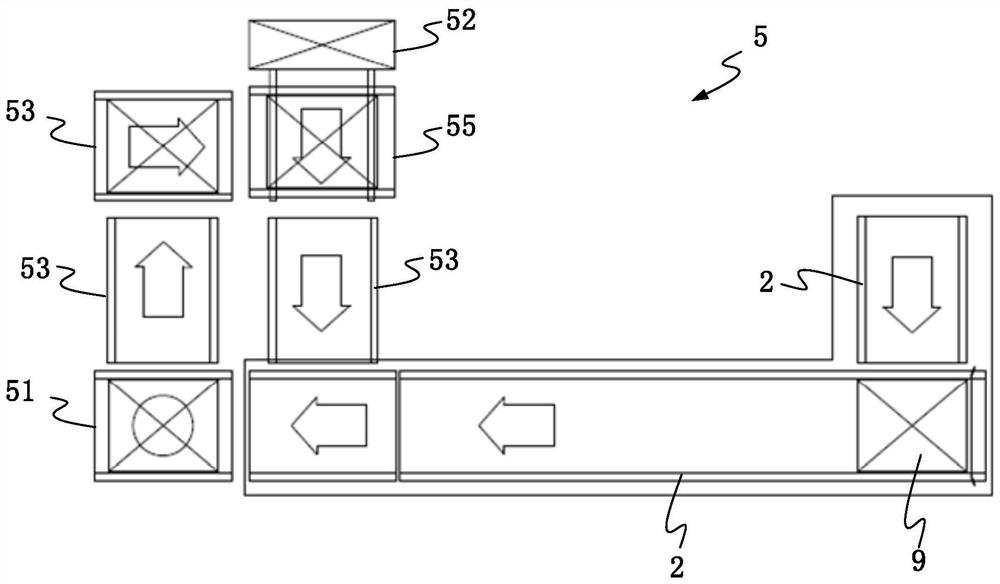

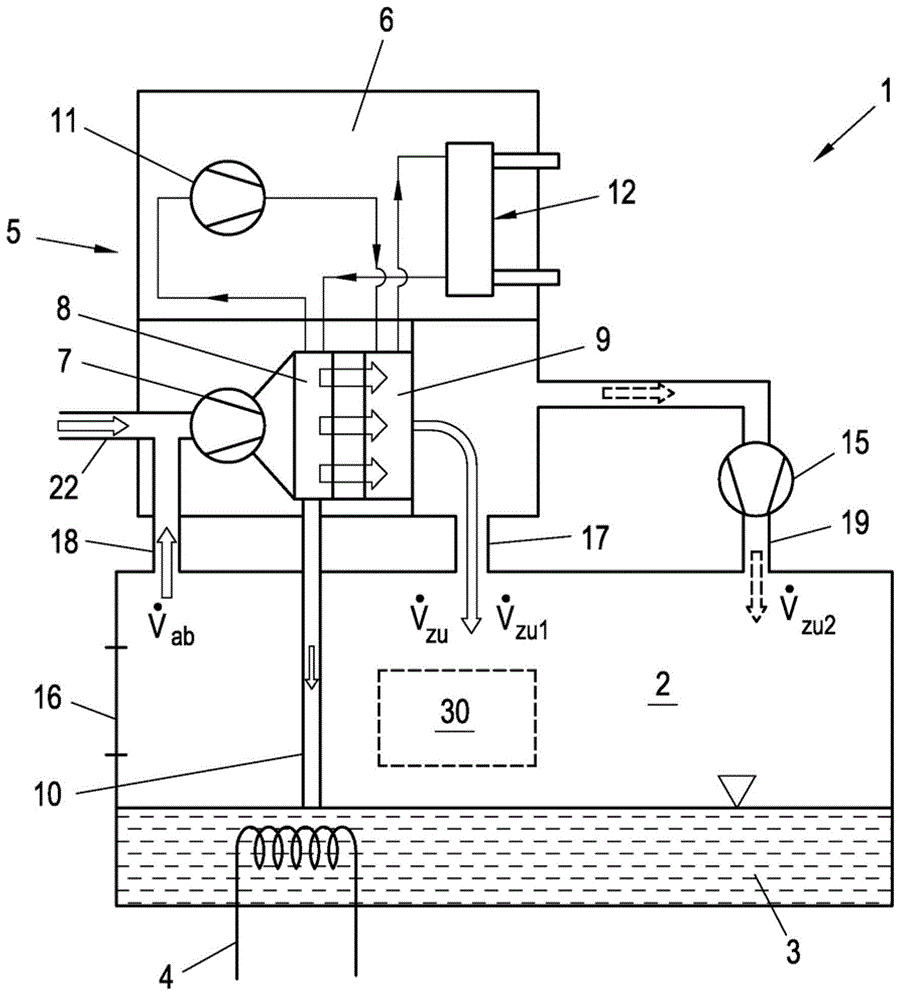

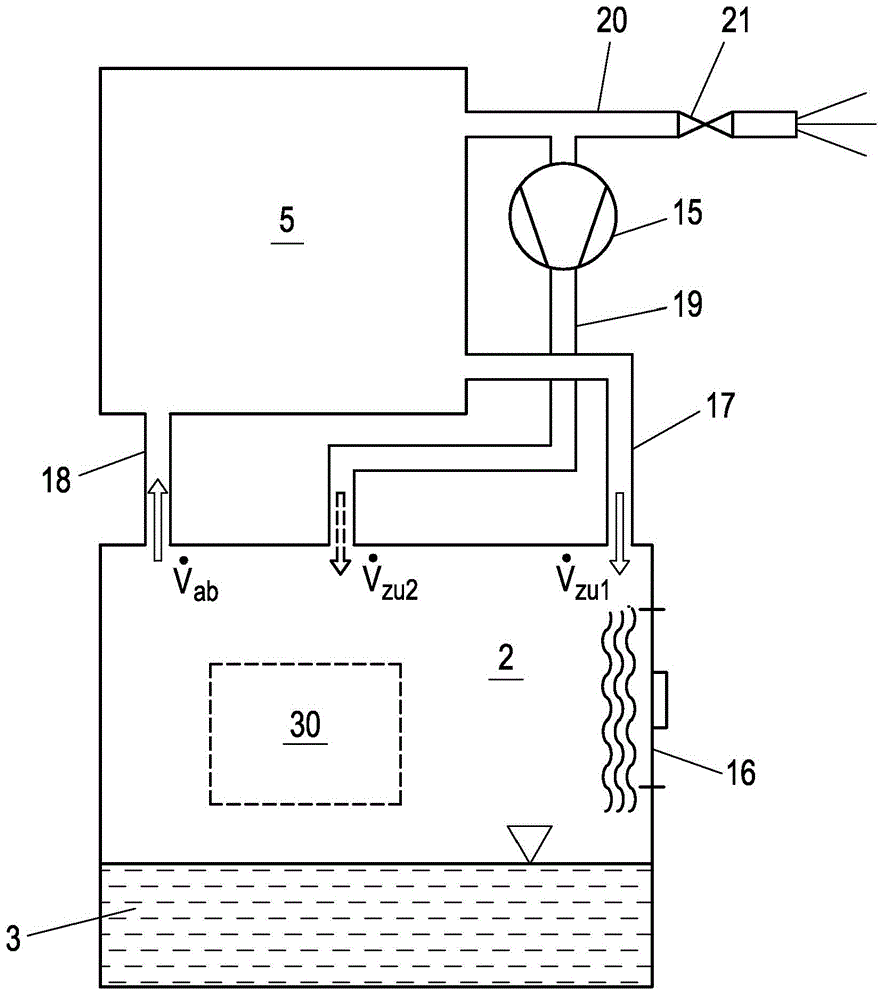

Method and a cleaning system for cleaning industrially produced components

InactiveCN103167916AConstant concentrationReduce consumptionGas treatmentRecuperative heat exchangersCleansing AgentsRefrigeration

In order to recover the resources (cleaning agents, heat) contained in the cleaning agent vapors suctioned off a cleaning system for cleaning industrially produced components, according to the invention the suctioned off waste air (I) is guided in a recovery device (5) via a heat register (9) of a refrigeration device (6), is thereby substantially heated to the temperature of the waste air (I), and the thus heated, dried waste air (I) is supplied to the cleaning chamber (2) in the region of a bulkhead door (16) as preheated, dry supply air (II).

Owner:TMS TURNKEY MFG SOLUTIONS

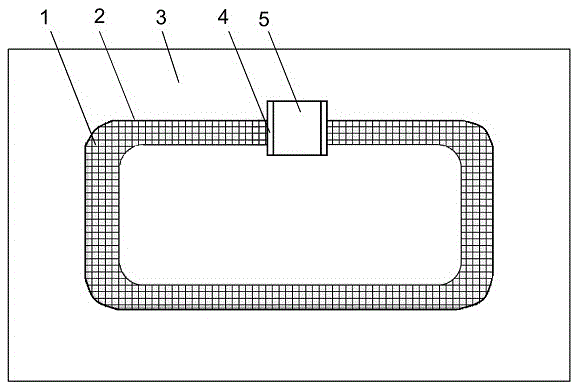

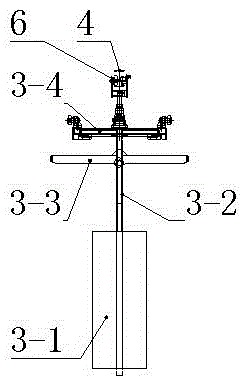

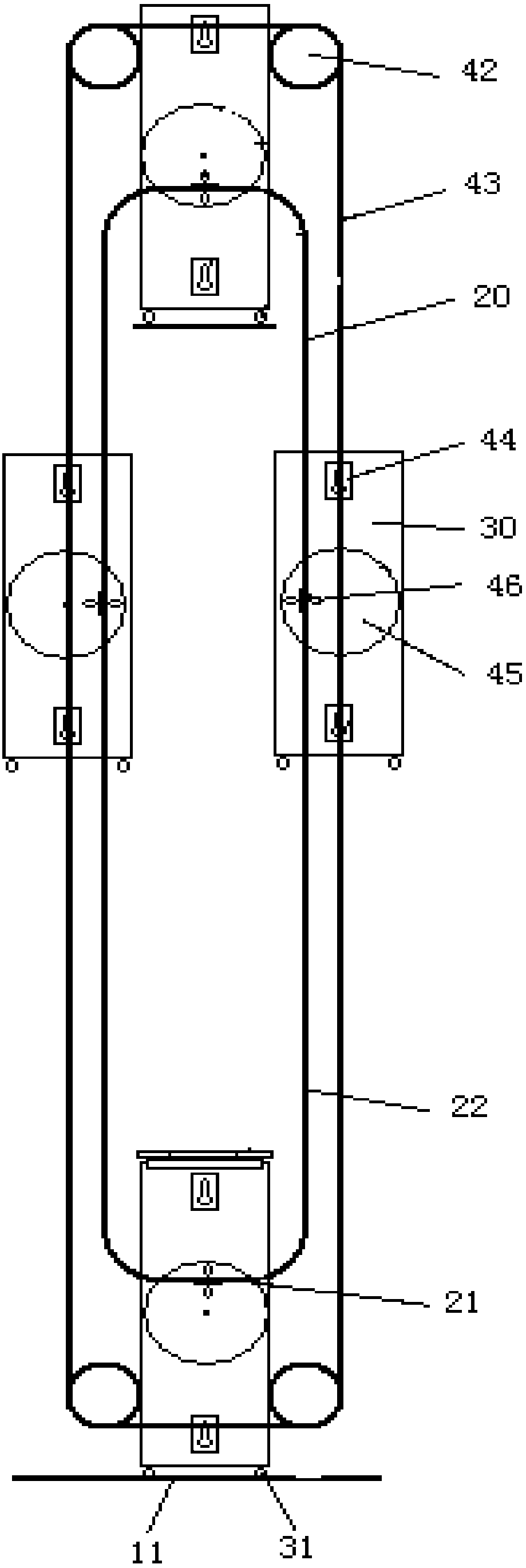

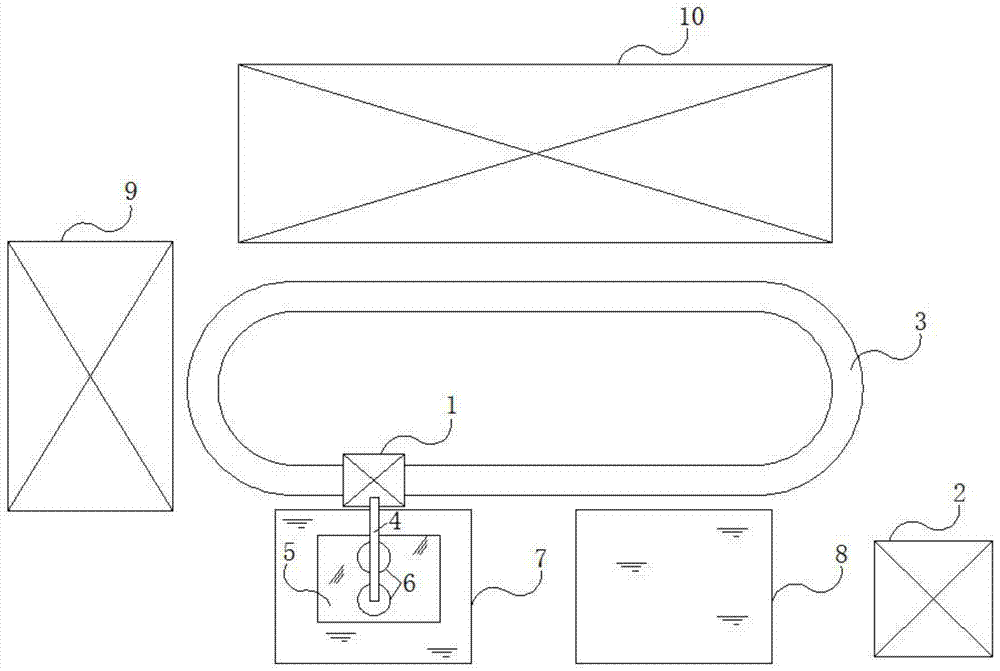

High temperature superconducting magnetic levitation apparatus

InactiveCN105553336ASmooth slidingRealize cycle operationMagnetic holding devicesLevitationHigh temperature superconducting

The invention discloses a high temperature superconducting magnetic levitation apparatus. The apparatus comprises a closed annular track and a high temperature superconducting strip magnetic levitation body, wherein the closed annular track is spliced by a series of permanent magnets; the closed annular track is fixedly arranged on a horizontal table type face plate, and the closed annular track and the horizontal table type face plate are integrated into one body; the high temperature superconducting strip magnetic levitation body is constantly positioned above the closed annular track; the high temperature superconducting strip magnetic levitation body adopts the high temperature superconducting strip; the high temperature superconducting strip is fixedly arranged at the bottom of a cavity of a low temperature container, and the high temperature superconducting strip and the low temperature container are integrated into one body; and a temperature condition for keeping the high temperature superconducting strip at a superconducting state is maintained in the low temperature container so as to enable the high temperature superconducting strip magnetic levitation body to be in a levitation state above the closed annular track under the superconducting state. According to the high temperature superconducting magnetic levitation apparatus, the low temperature container that is in static levitation above the track is pushed by an external force; the low temperature container stably slides above the closed track in the levitation manner, and circulating periodical operation of the low temperature container under the levitation state can be realized; and in addition, the apparatus is simple in structure, convenient to control, low in operational energy consumption and high in effective magnetic levitation force.

Owner:SHANGHAI UNIV

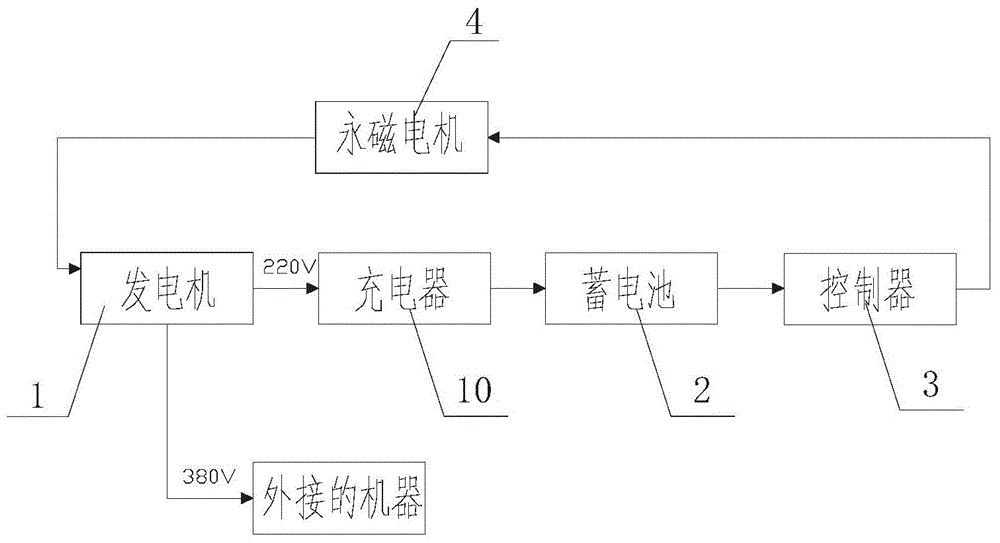

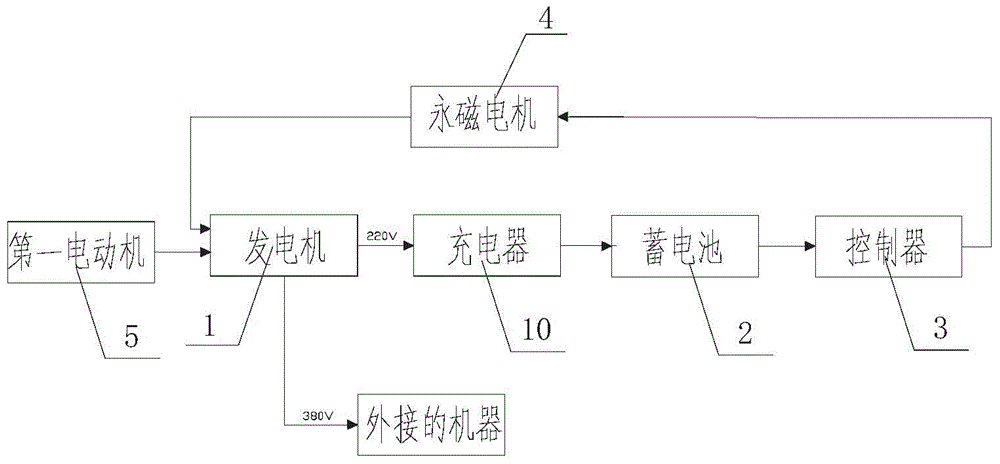

Circulation power generation system

InactiveCN104578702AAchieve cycleSimple structureDynamo-electric machinesElectric power systemPermanent magnet motor

The invention discloses a circulation power generation system which comprises a power generator, a charger, a storage battery and a permanent magnet motor. The power generator comprises a first output opening and a second output opening. The first output opening of the power generator is connected with the input of the charger. The output of the charger is connected with the input of the storage battery. The output of the storage battery is connected with the input of the permanent magnet motor. The output of the permanent magnet motor is in transmission connection with the input of the power generator. The circulation power generation system is simple in structure, easy to achieve and capable of lowering electric power loss effectively, and electric power circulation operation is achieved.

Owner:袁伟兴

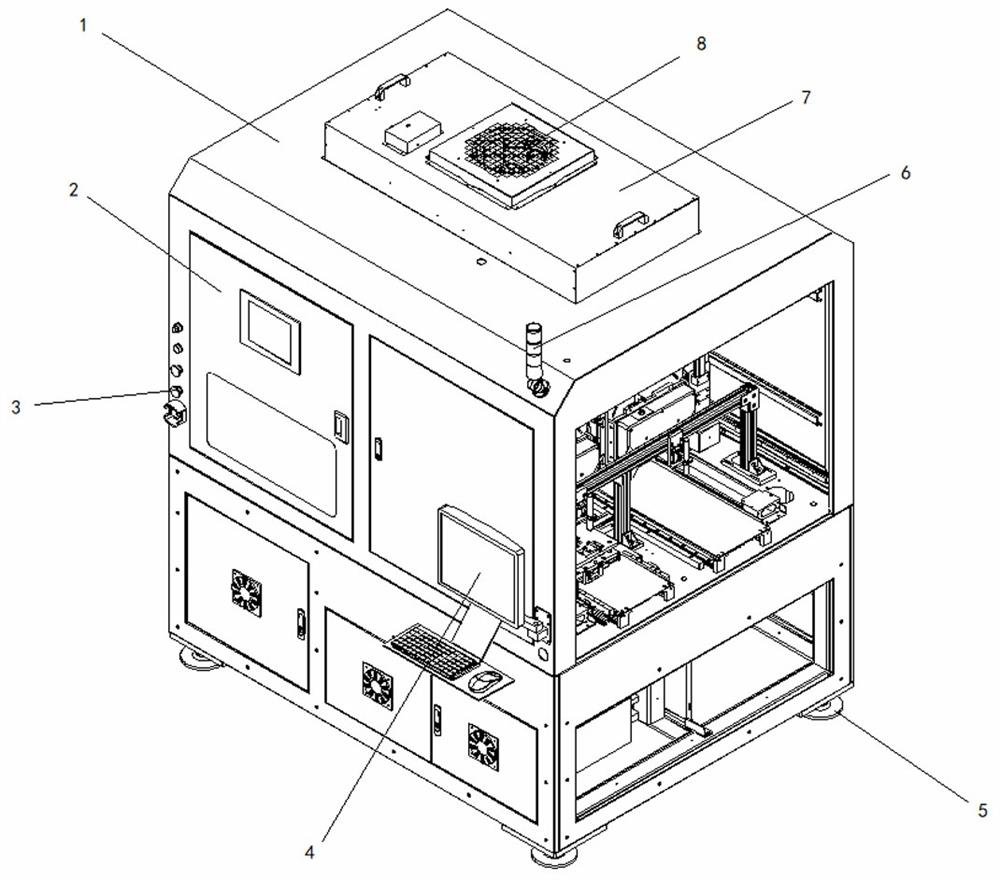

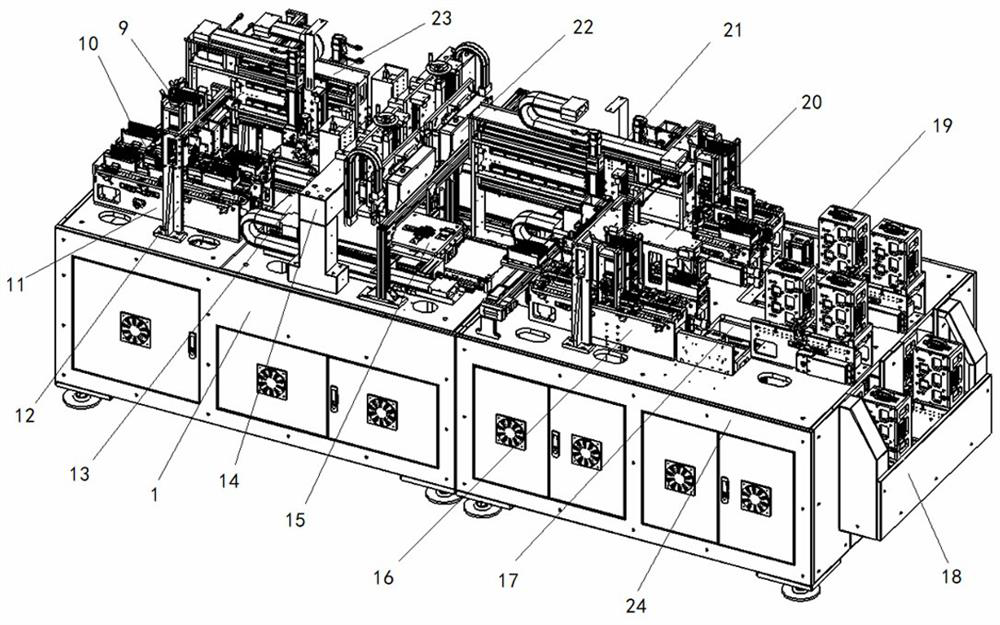

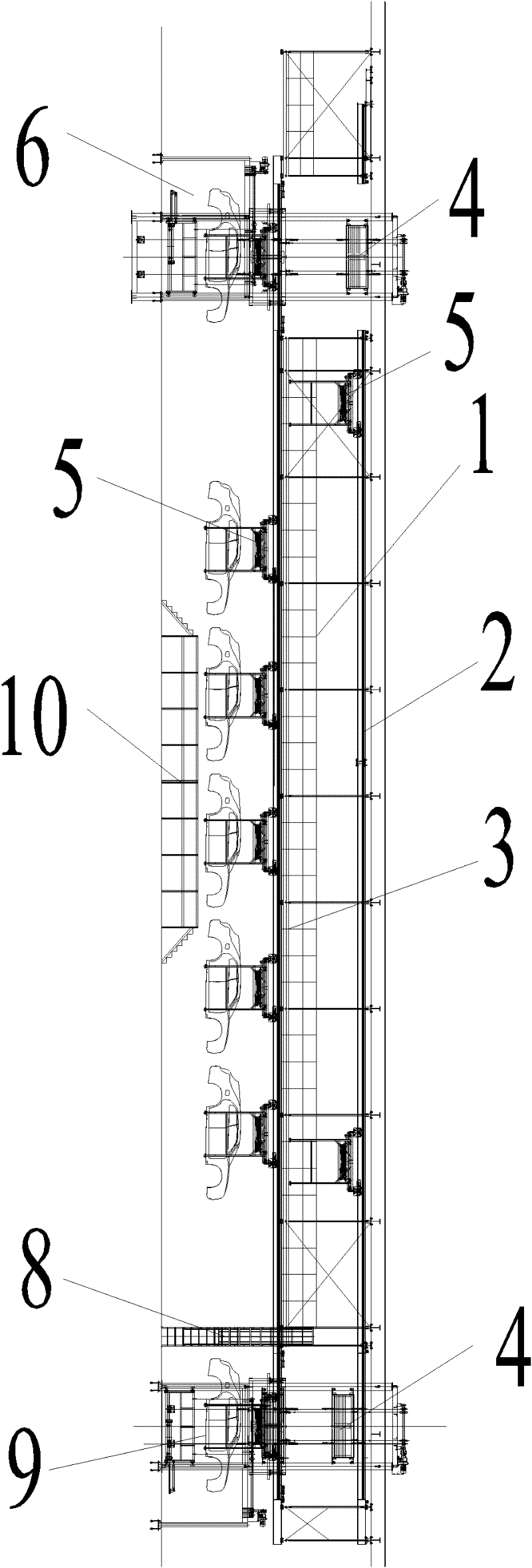

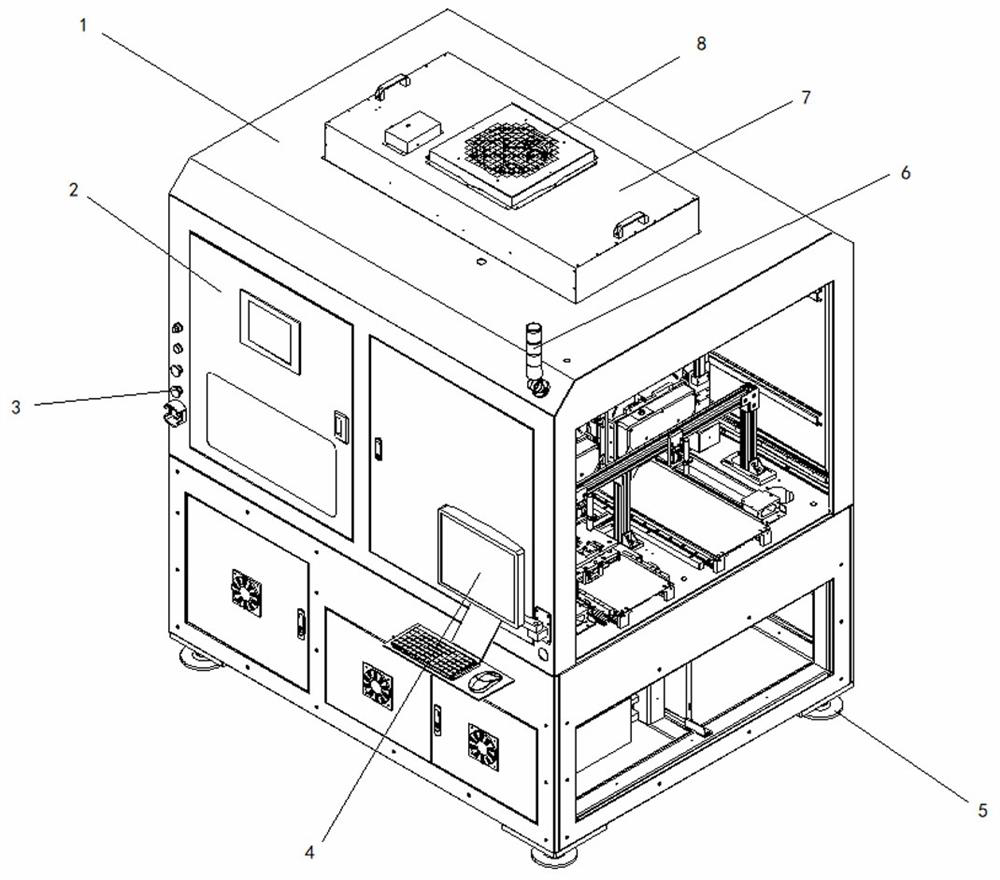

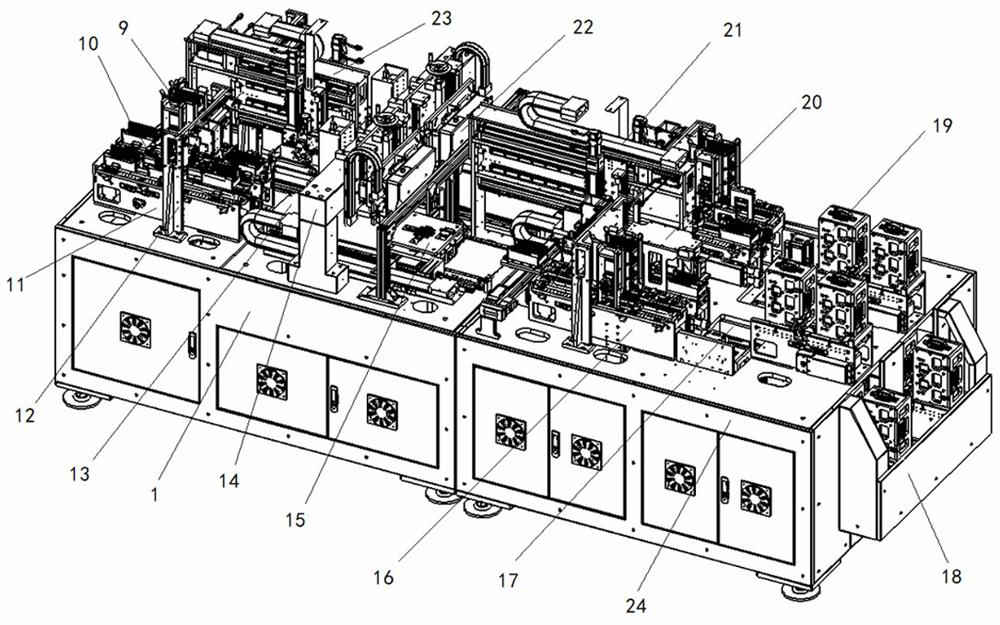

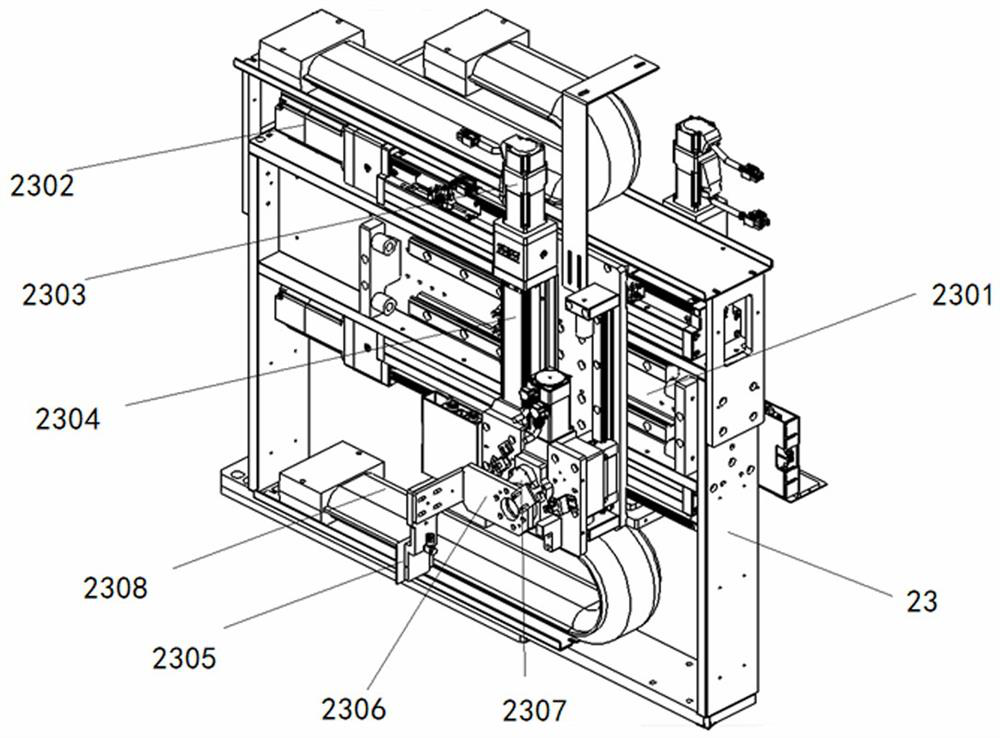

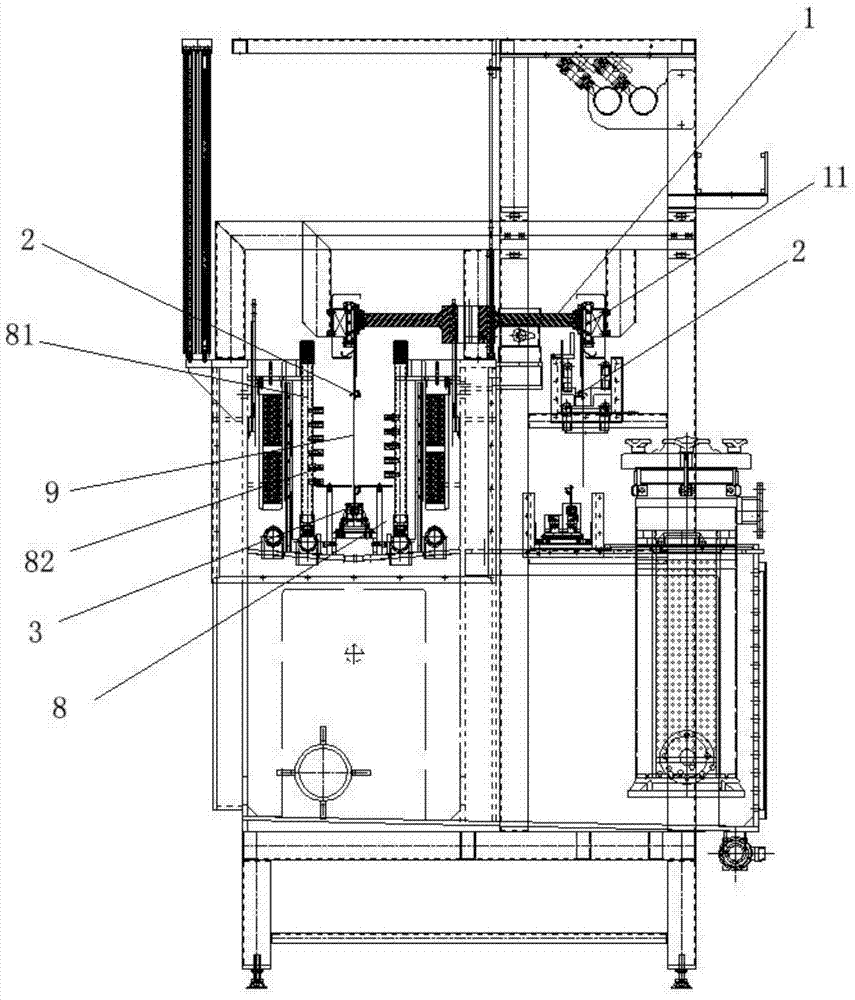

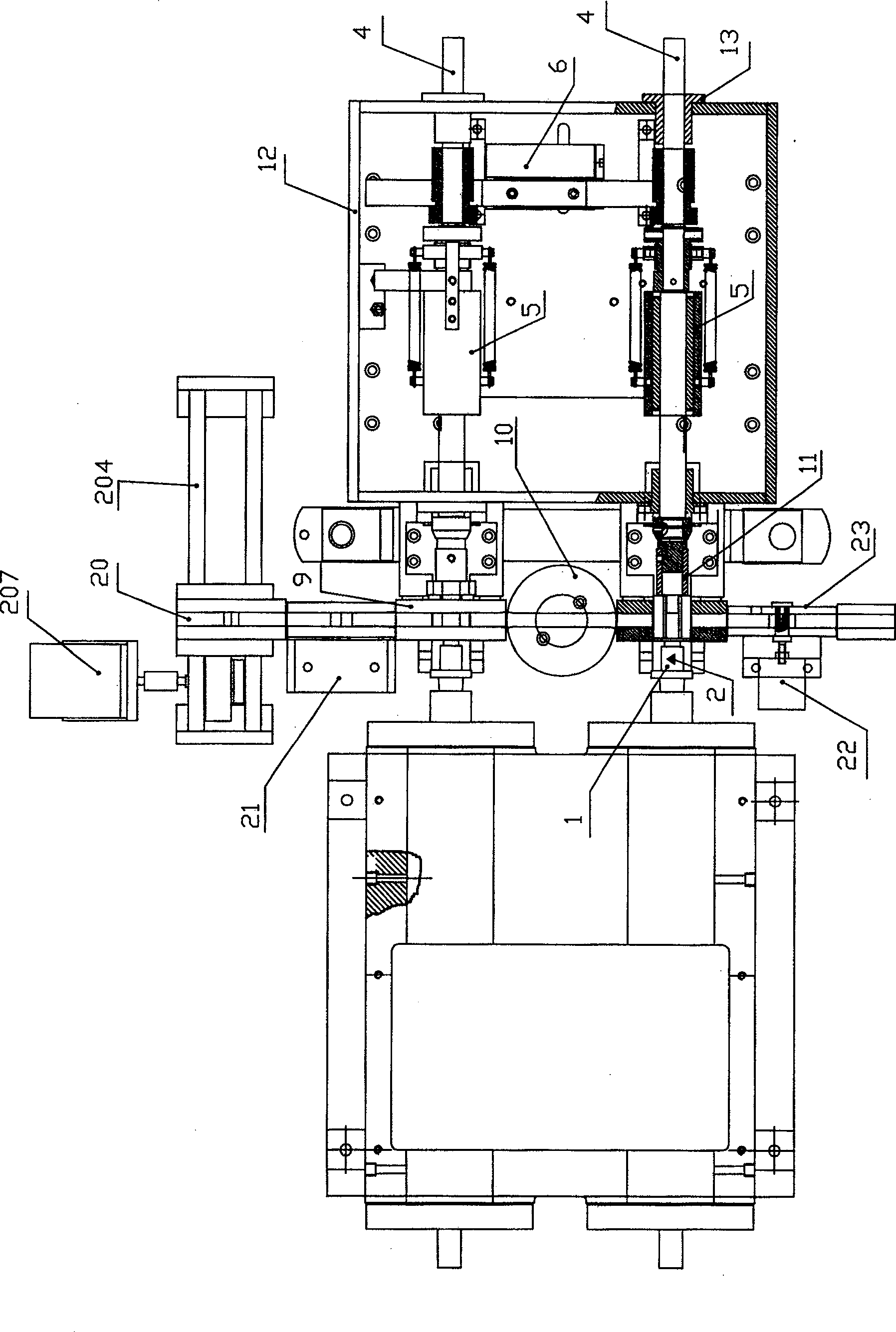

Wafer color detection equipment

ActiveCN114582765AImprove detection efficiencyFlexibility to move withFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringColor detection

The invention discloses wafer color detection equipment which comprises a feeding module, a detection module and a discharging module which are sequentially arranged at the top of the detection equipment, and the feeding module comprises a feeding conveying mechanism, a supplementing conveying mechanism and a feeding grabbing mechanism; a feeding buffering mechanism is arranged on the feeding conveying mechanism, and a buffering pushing mechanism can push the wafer box on the feeding pushing chain into a buffering cavity for buffering; the detection module comprises a detection support frame and at least one visual detection mechanism arranged on one side of the detection support frame, the visual detection mechanism can perform photographing detection on the wafer, the detection module further comprises a marking mechanism, and when the visual detection mechanism detects wafer defects, the marking mechanism performs marking on the surface of the wafer; therefore, the wafers can be classified conveniently. A box body conveying chain is arranged on one side of the discharging conveying mechanism, a plurality of storage boxes are arranged on the box body conveying chain, and the wafer boxes are pushed into the storage boxes through the pushing mechanical arm.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

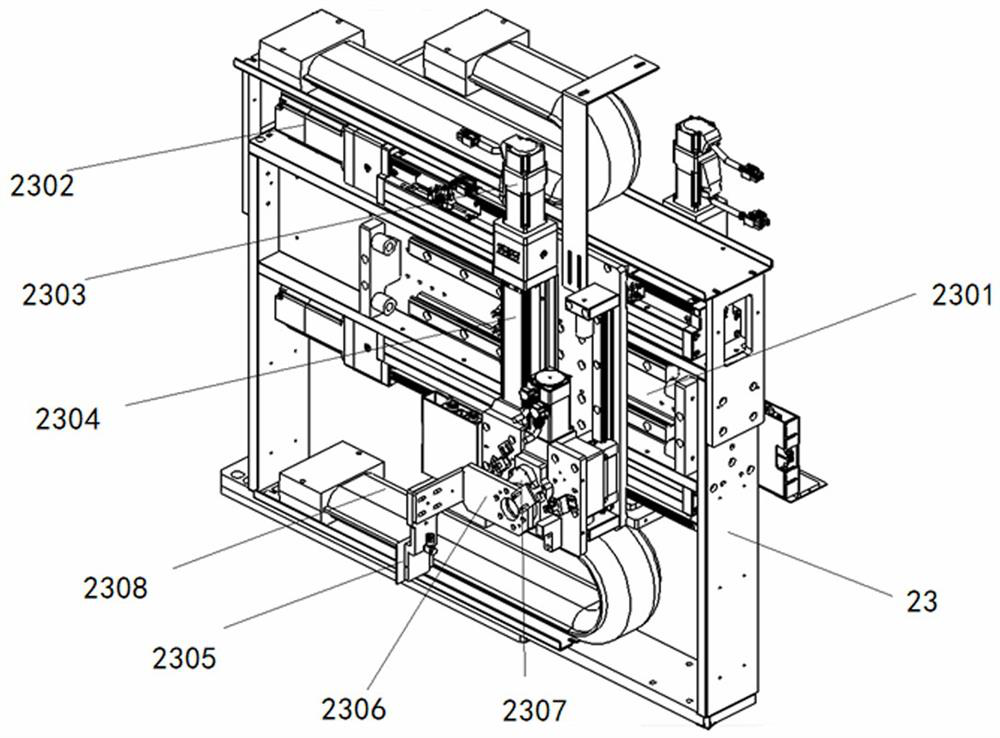

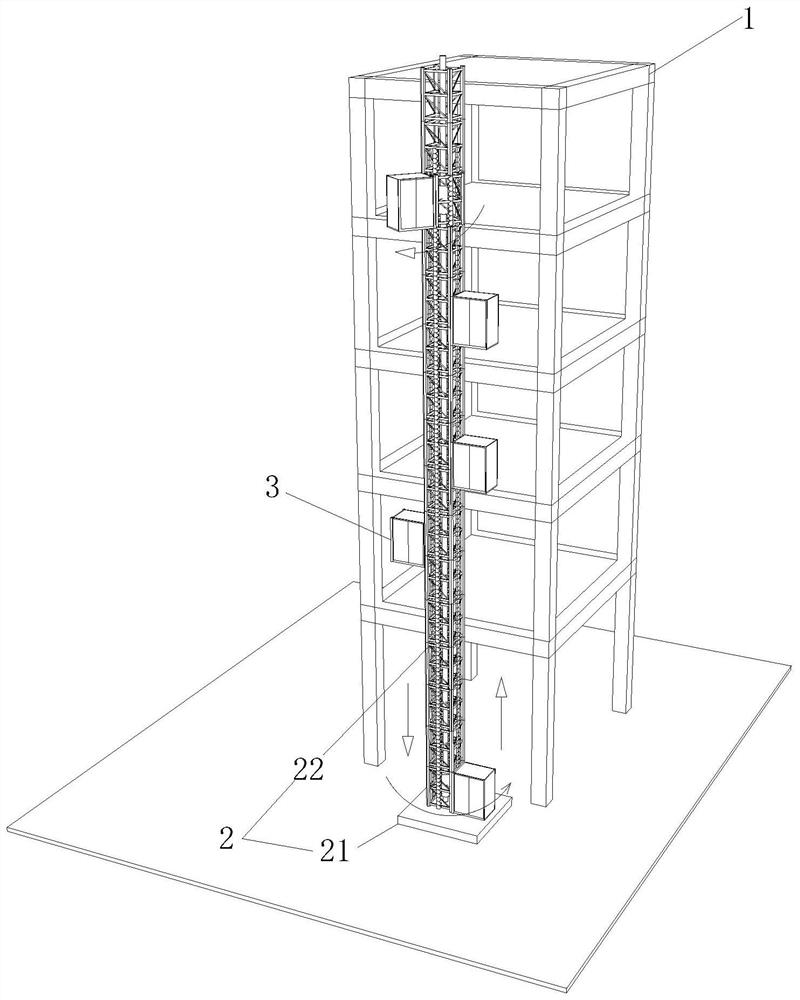

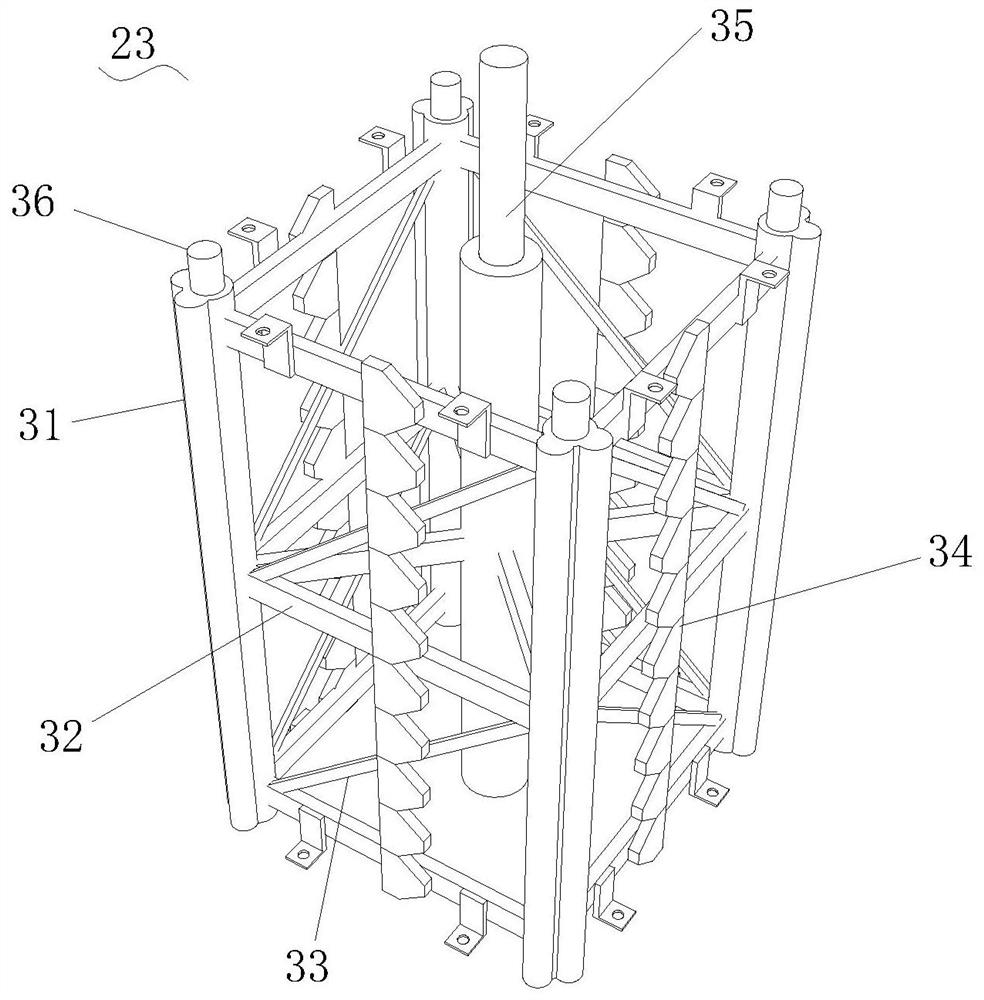

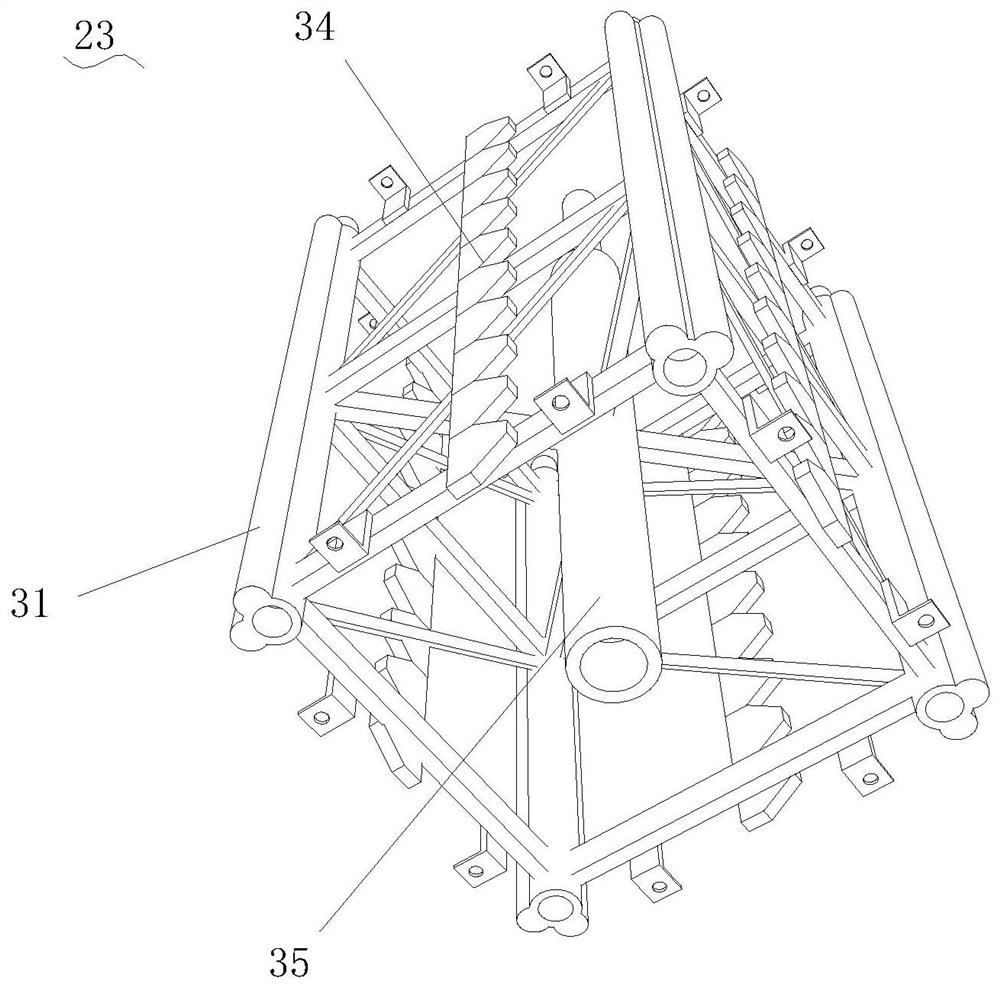

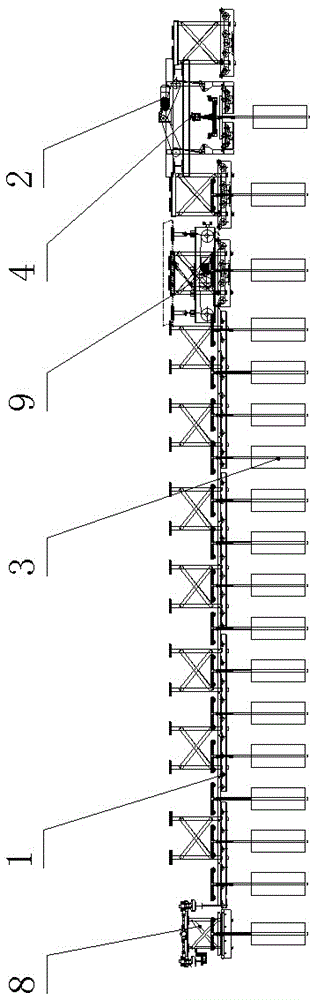

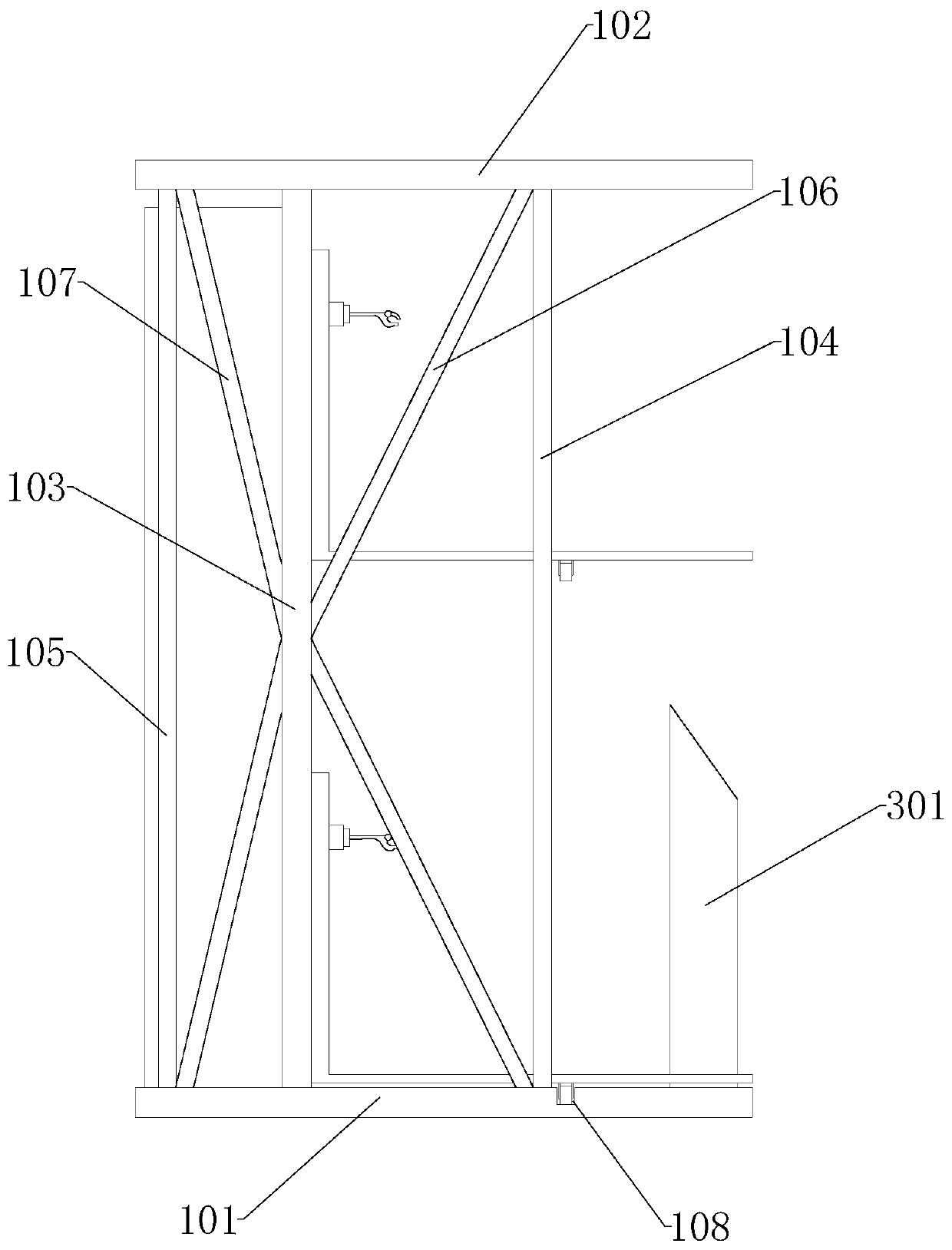

Intelligent circulating type people and goods elevator system and using method

ActiveCN112607557ARealize cycle operationImprove construction efficiencyElevatorsBuilding liftsAutomotive engineeringElevator system

The invention discloses an intelligent circulating type people and goods elevator system and a using method. The intelligent circulating type people and goods elevator system comprises a derrick system and a plurality of lift cars, the derrick system comprises a base and a derrick body arranged on the base, the derrick body comprises a plurality of standard joints which are vertically spliced in sequence, a rotating joint and a rotating control joint, the rotating joint and the rotating control joint are arranged at the bottom and the top of the derrick body, an ascending guide rail and a descending guide rail are arranged on two side parts of the frame body, the rotating control joint is used for controlling the rotating joint to rotate along the axis, the lift cars ascend along the ascending guide rail or descend along the descending guide rail, and the lift cars are switched between the ascending guide rail and the descending guide rail through rotating the control joint. According to the intelligent circulating type people and goods elevator system, the lift cars circularly run between the ascending guide rail and the descending guide rail, the plurality of lift cars do not influence one another, the vertical transportation efficiency of people and goods is greatly improved in a multi-lift-car, automatic and full-circulation mode, and development of the high-rise and super high-rise construction technology is assisted.

Owner:SHANGHAI NO 4 CONSTR

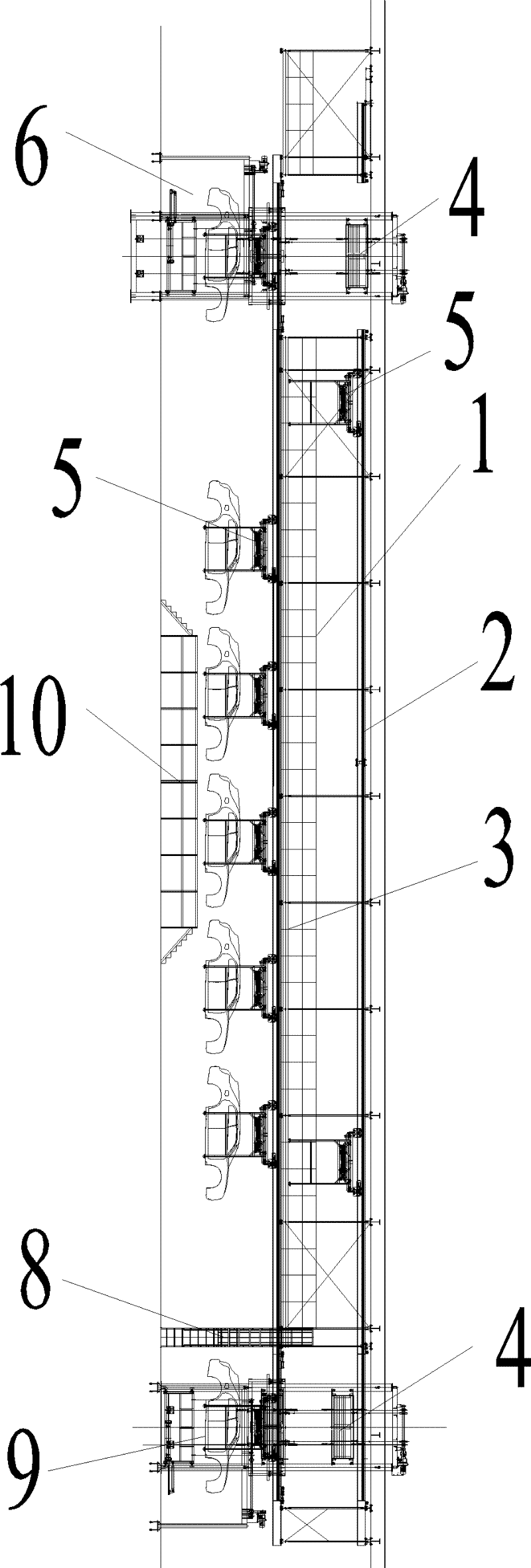

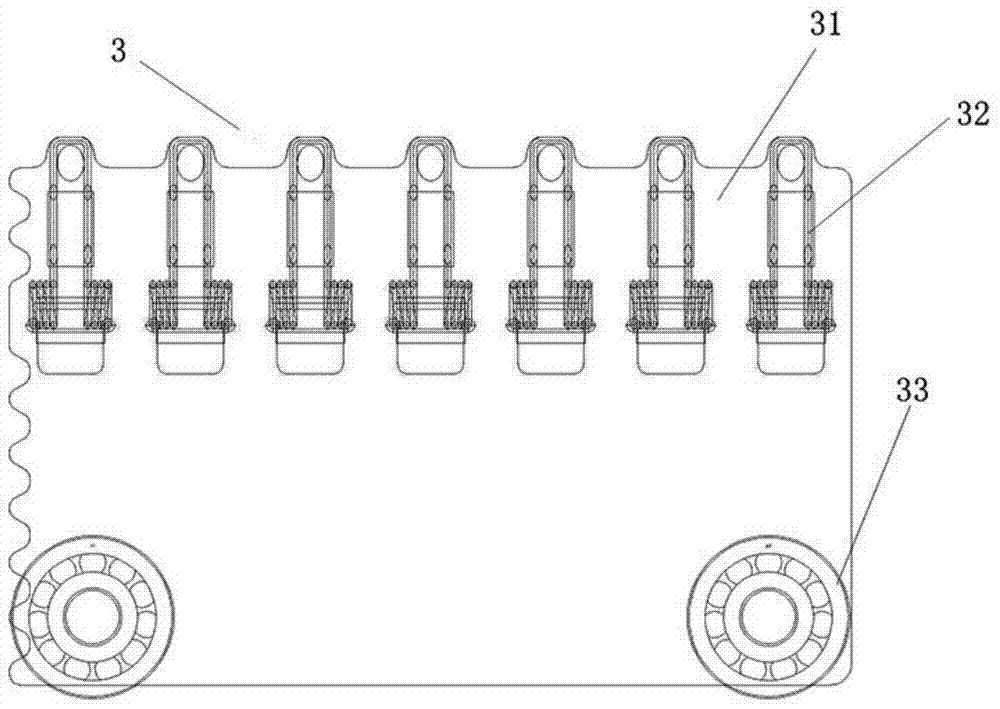

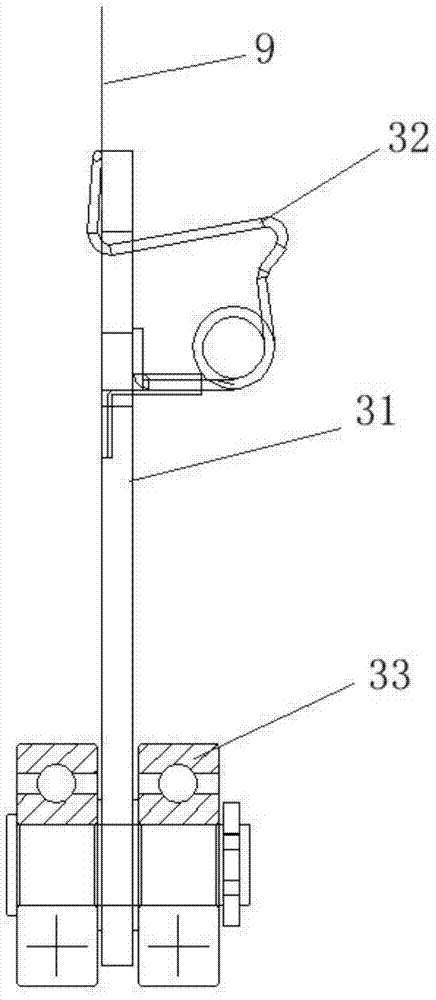

Car door conveying device

InactiveCN105905553ARealize cycle operationManufacturing cost input reductionMechanical conveyorsClamp connectionCar door

The invention discloses a car door conveying device which comprises lifting appliances sliding on main roller paths. Each lifting appliance comprises a lower-layer hanging bracket and two hanging brackets oppositely arranged on the lower-layer hanging bracket; a plurality of circuiting sliding rail units are arranged on the main roller paths; a lifting appliance separation and combination device is arranged at the joint of each main roller path and the corresponding circuiting sliding rail unit; each circuiting sliding rail unit comprises a sliding bracket sliding on a circuiting rail unit through traveling wheels; each sliding bracket is provided with an upper-layer hanging rod in clamped connection with the corresponding lower-layer hanging bracket; each lifting appliance separation and combination device comprises a machine frame with guide columns and a lifting frame driven by a motor to move on the guide columns; and traveling roller paths are arranged at the lower ends of the lifting frames. Compared with the prior art, the problems that an existing car door conveying device is large in occupied area and high in cost can be solved.

Owner:DONGFENG LIUZHOU MOTOR

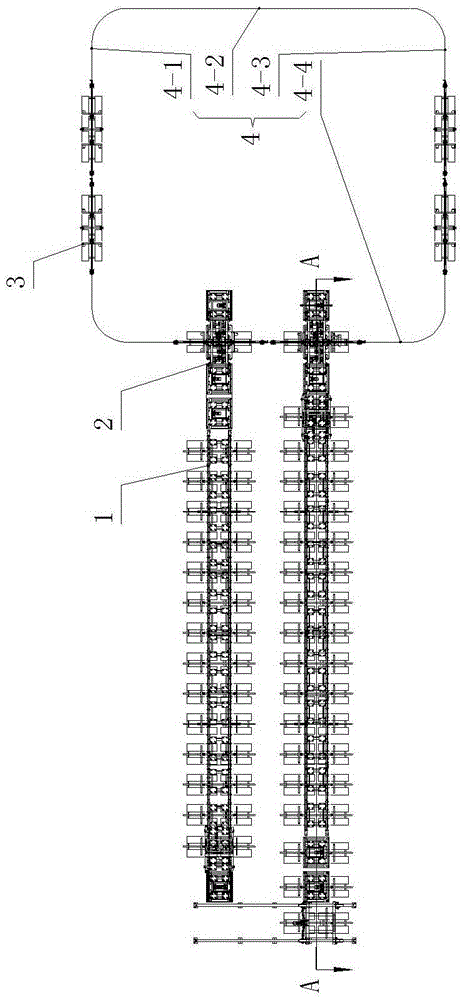

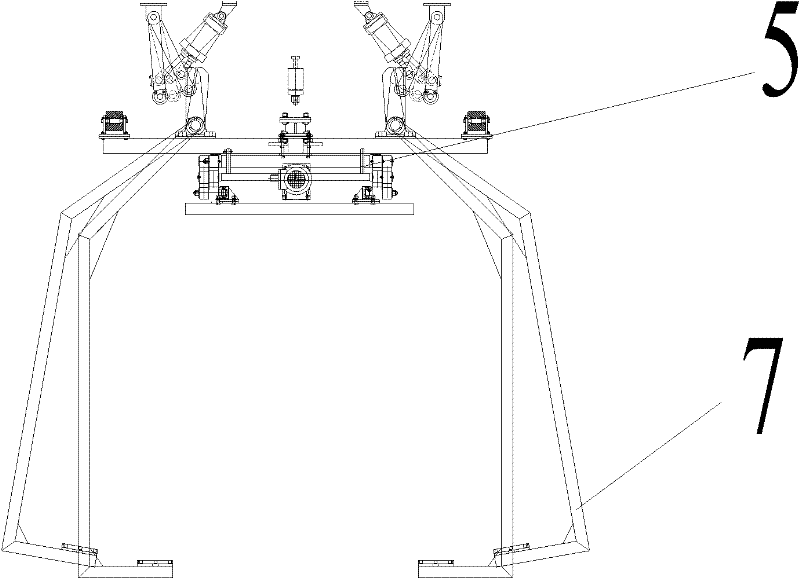

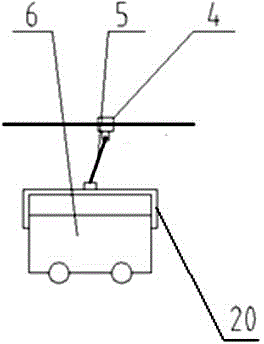

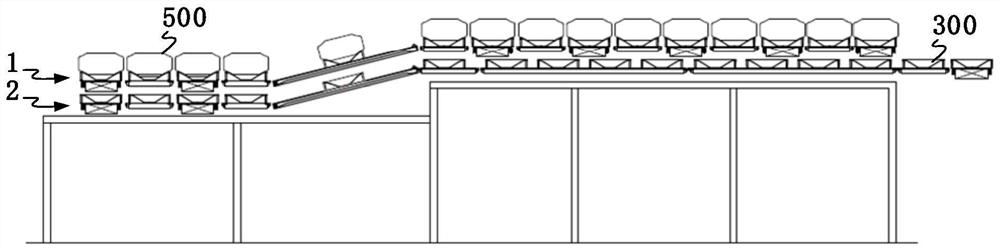

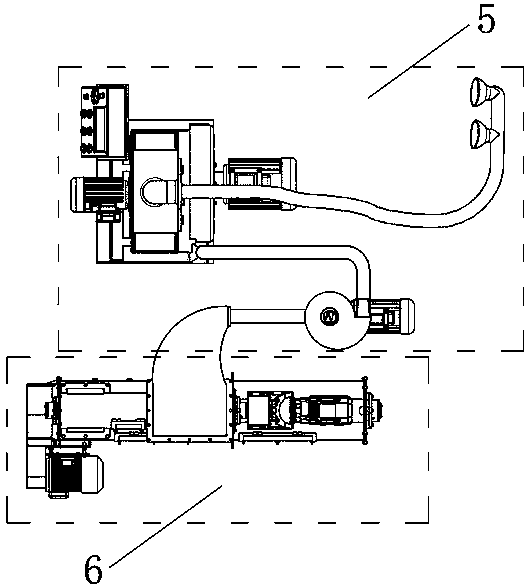

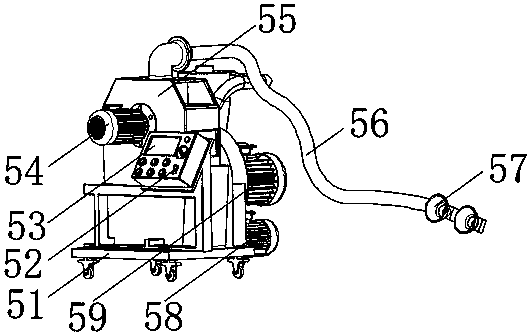

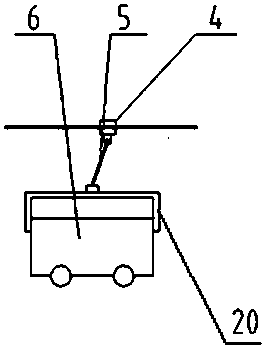

Overhead conveying system of disassembly line for scrapped automobile

InactiveCN102530126ARealize cycle operationImprove dismantling efficiencyVehicle dissasembly recoverySolid waste disposalAutomotive engineeringProgrammable logic controller

The invention discloses an overhead conveying system of a disassembly line for a scrapped automobile. The overhead conveying system is connected with a front assembly conveying system of the disassembly line, and comprises a supporting overhead frame and a sliding line, wherein the sliding line is arranged on the supporting overhead frame, one end of the supporting overhead frame is a scrapped automobile input end which is connected with the front assembly conveying system, the other end of the supporting overhead frame is a scrapped automobile output end, elevators are arranged at the scrapped automobile input end and the scrapped automobile output end, exits are arranged between the scrapped automobile input end and the scrapped automobile output end, and lead to an engine disassembling station and a rear axle disassembling station, and a self-propelled trolley is arranged on the supporting overhead frame, can automatically slide along the sliding line, and is used for grabbing the scrapped automobile to move from the scrapped automobile input end to the respective exits. According to the technical scheme, respective disassembling stations can be connected effectively, and the scrapped automobile can be quickly moved to the respective disassembling stations for disassembly through the self-propelled trolley, so that high conveying efficiency is realized, and therefore disassembling efficiency of the whole disassembly line for the scrapped automobile is increased; and moreover, as the overhead conveying system is controlled by a PLC (Programmable Logic Controller), the automation degree is high.

Owner:安徽韦尔汽车科技有限公司

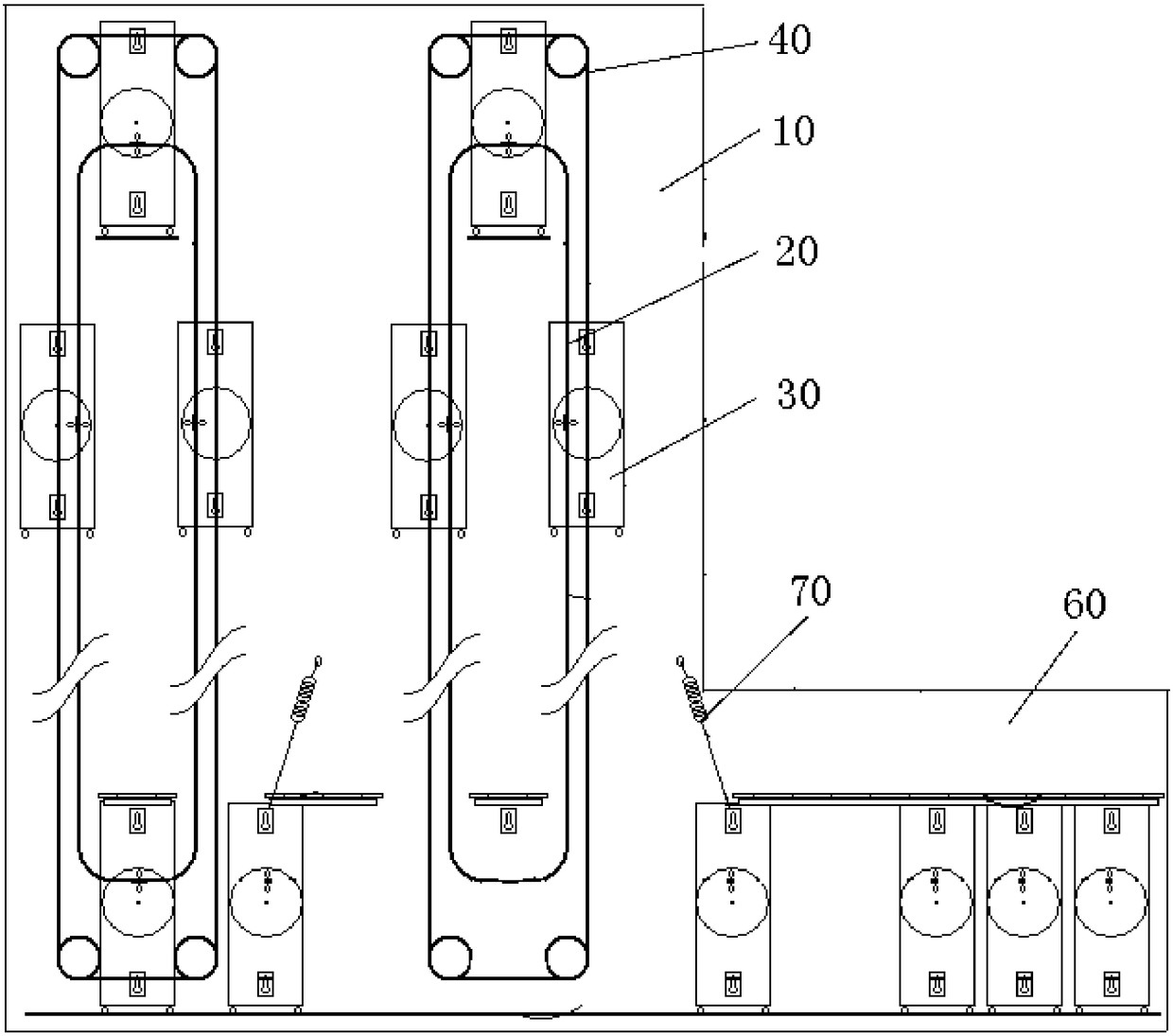

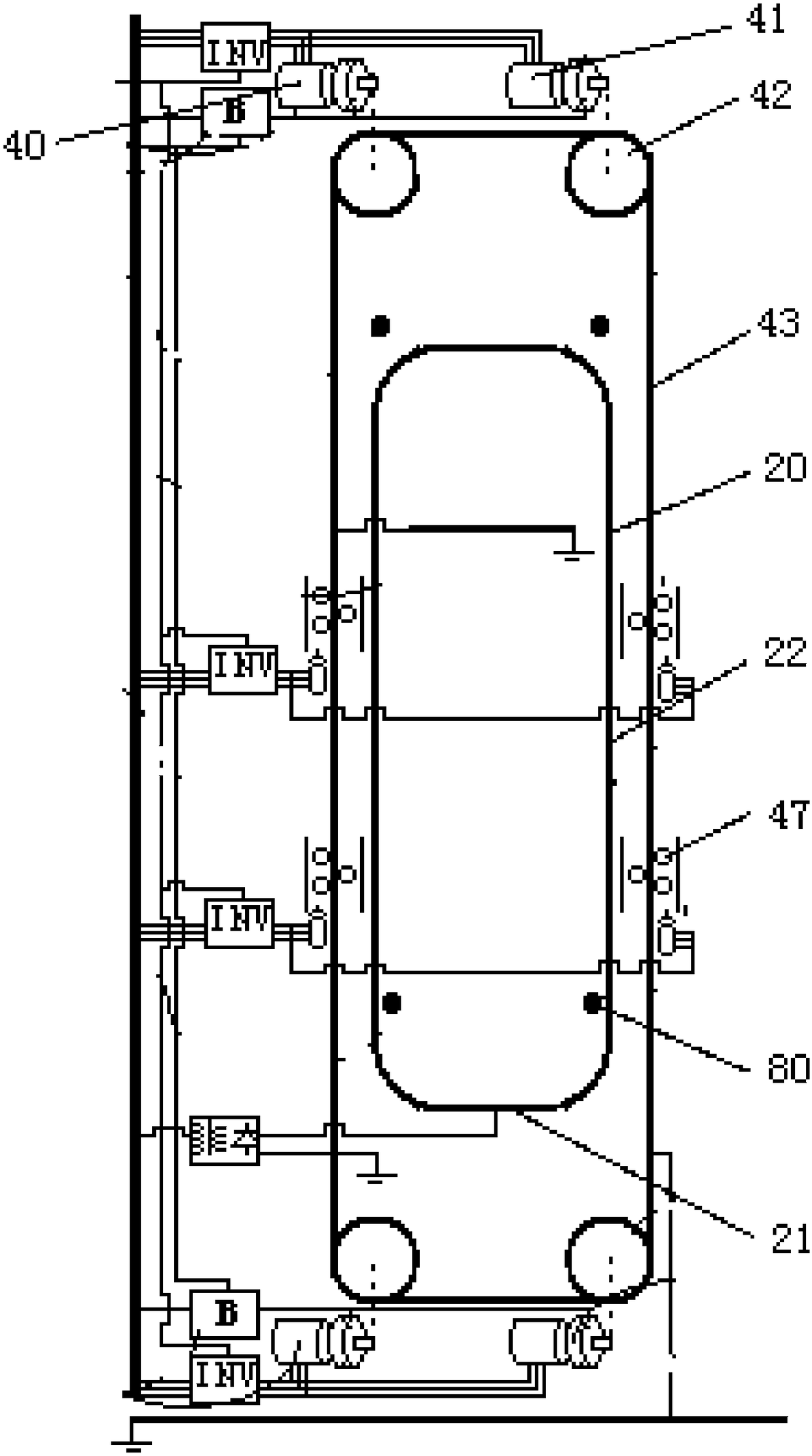

Circulating elevator

ActiveCN108249256AIncrease carrying capacityRich user experienceElevatorsBuilding liftsEngineeringMechanical engineering

The invention relates to a circulating elevator comprising a well, and guide rails, a car and a traction device which are arranged in the well; the guide rails comprise two horizontal guide rails arranged in parallel and two vertical guide rails arranged in parallel, and a closed structure is enclosed by the two horizontal guide rails and the two vertical guide rails; the car is slidably arrangedon the guide rails, and internally provided with seats slidably; the traction device is in transmission connection with the car, and used for pulling the car to slide on the guide rails; and the wellis internally provided with a plurality of guide devices which are in signal connection with the traction device. The circulating elevator provided by the invention has the advantages of high carryingcapacity and space utilization rate, low cost, humanized design and the like.

Owner:HITACHI ELEVATOR CHINA

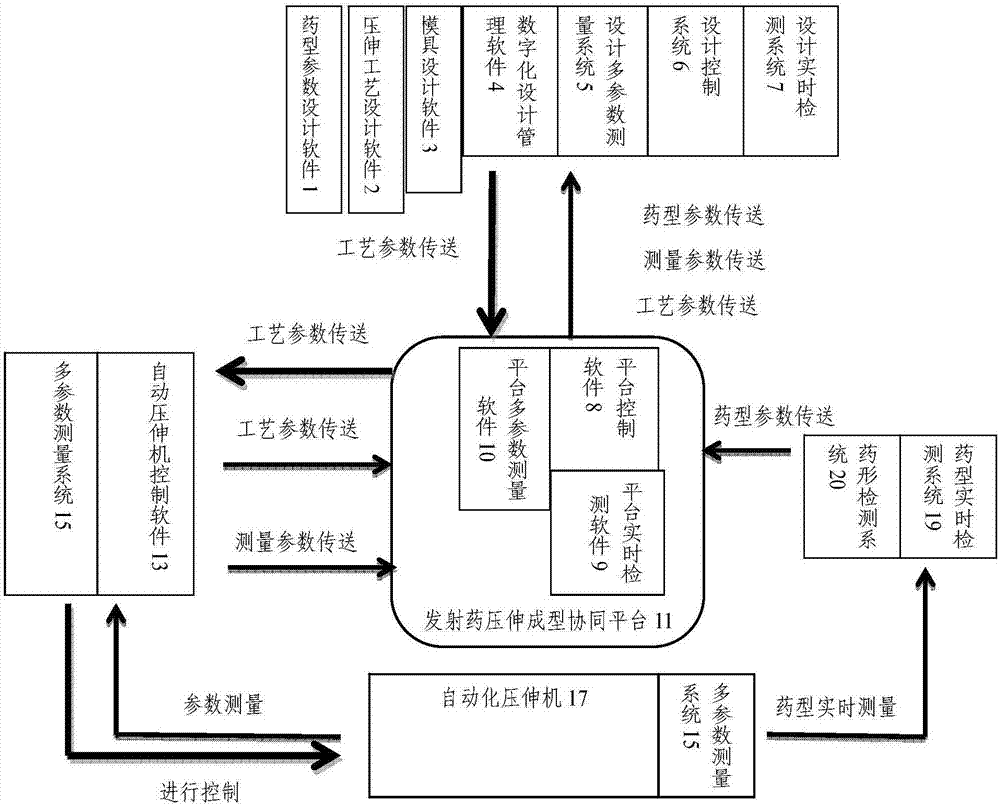

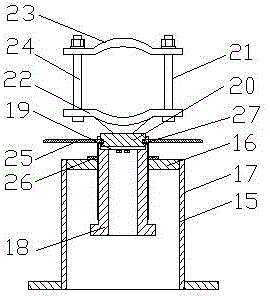

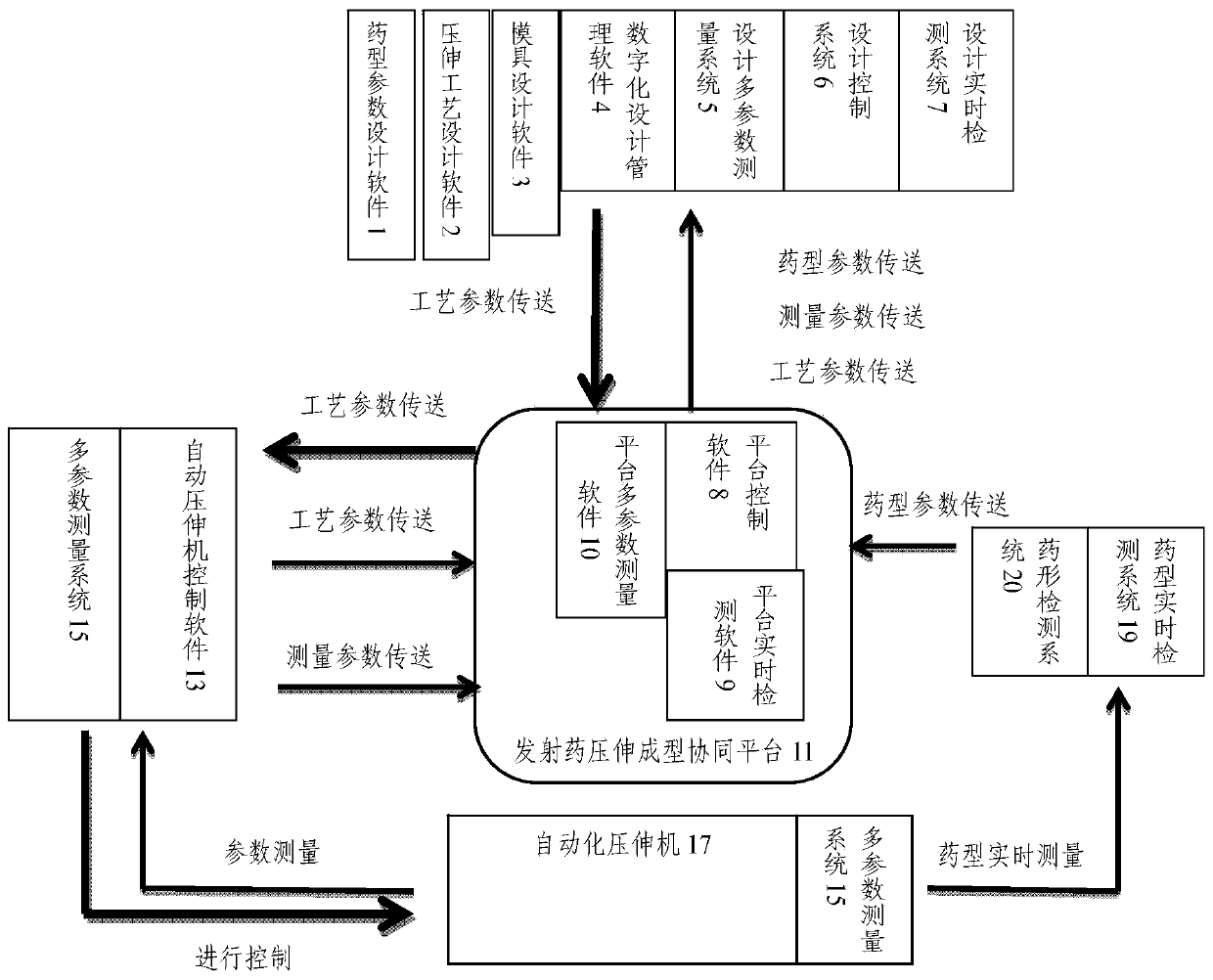

Companding moulding method for gun propellant with predetermined design size

ActiveCN107480388AImprove quality consistencyFill the gap in the countryDesign optimisation/simulationSpecial data processing applicationsSize parameterProcess design

The invention discloses a gun propellant companding moulding method which can achieve process design, parameter push and parameter measurement cycle operation, and conduct real-time inverse calculation of design data to obtain suitable companding process parameters. The method uses a collaborative platform technology, and achieves process design, parameter push, reading and analyzing of parameter measurement results, and process cycle operation. Compared with the existing technology, the parametric real-time circulation of design, companding and detection links is achieved, and the foundation is provided for synchronous correction feedback; the technology of target parameter and detection parameter data real-time contrast is used to achieve real-time judgment on the dimension parameters of gun propellant products. Compared with the existing technology, the quality criteria of product online parameters can be provided in real time.

Owner:XIAN MODERN CHEM RES INST

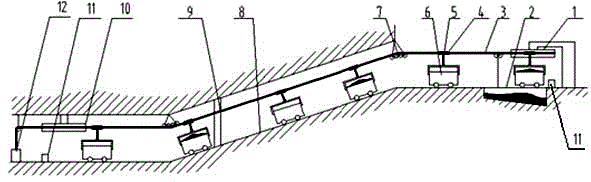

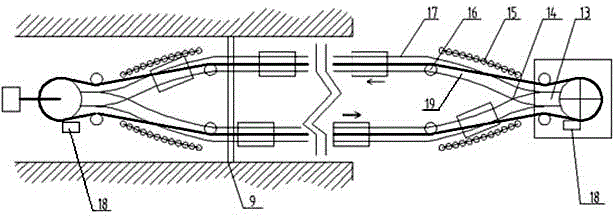

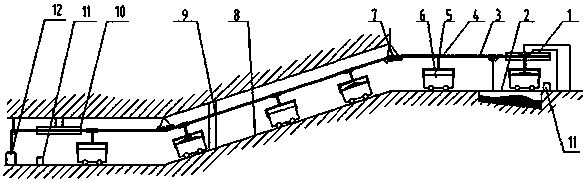

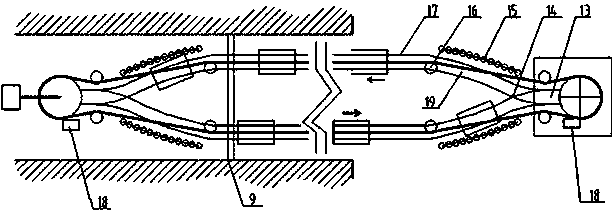

Steel wire rope dragged rail tramcar continuous conveying system

ActiveCN104670245ARealize cycle operationAvoid the problem of excessive turning radiusTramway railsRope railwaysTraction systemEngineering

The invention discloses a steel wire rope dragged rail tramcar continuous conveying system which comprises a steel wire rope traction system and a rail tramcar running system, wherein a steel wire rope driving device (1) is arranged at a horizontal outlet of a shaft mouth; a tail wheel (10) is fixed on a horizontal top plate of a shaft bottom; a tensioning device (12) is arranged at a horizontal roadway ground of the shaft bottom and is connected with the tail wheel (10); the upper end of a side dump tramcar (6) is connected with the steel wire rope (3) by a connecting device; the lower end of the side dump tramcar (6) is connected with a rail (8) through wheels; the rail (8) is composed of a loading / unloading place rail (13), a railway turnout (14), a bending rail (19) and a parallel rail (17); the up-going and down-going parallel rail (17) passes through the bending rail (19) and the railway turnout (14) to the loading / unloading place rail (13); car arresters (11) are respectively arranged at two ends of the loading / unloading place rail (13). The conveying procedure is performed automatically without human interference, the tramcar does not need to hook up and down, the loading and unloading time is shortened, and the downhole conveying efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

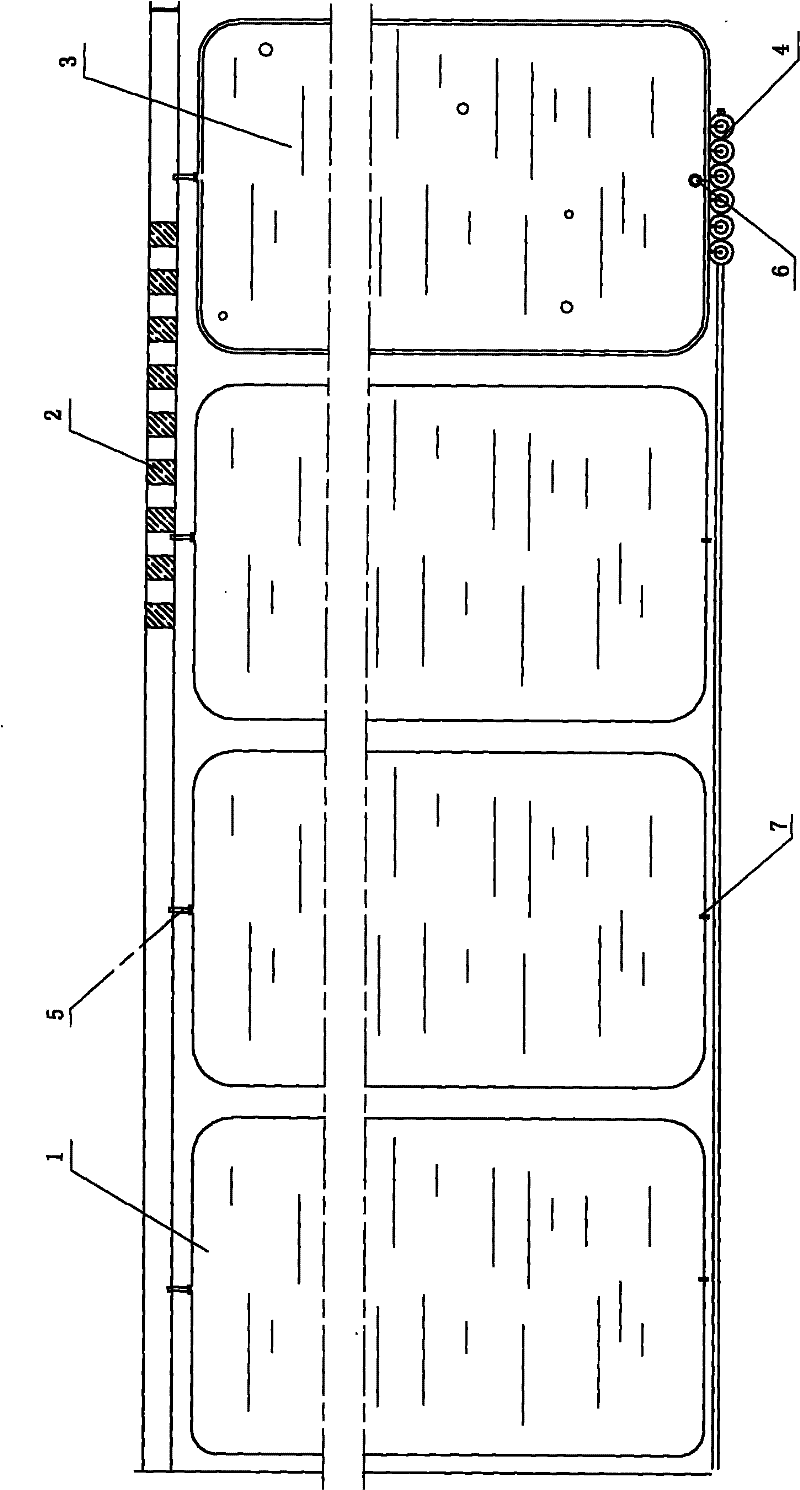

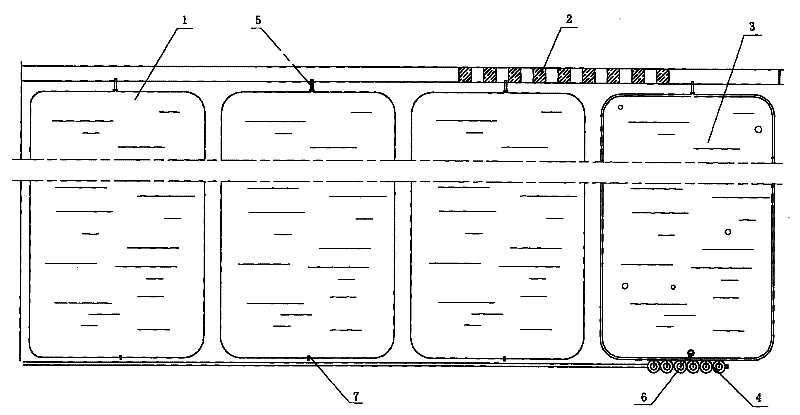

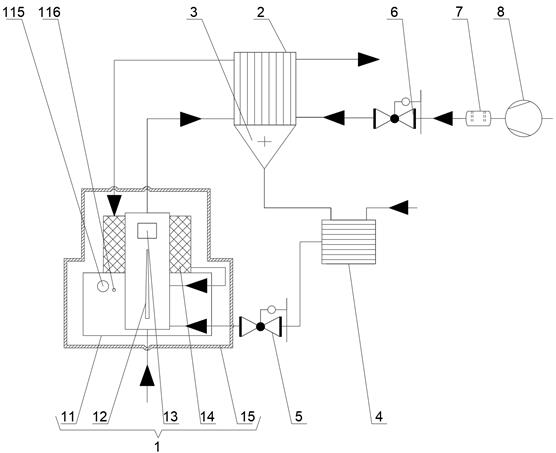

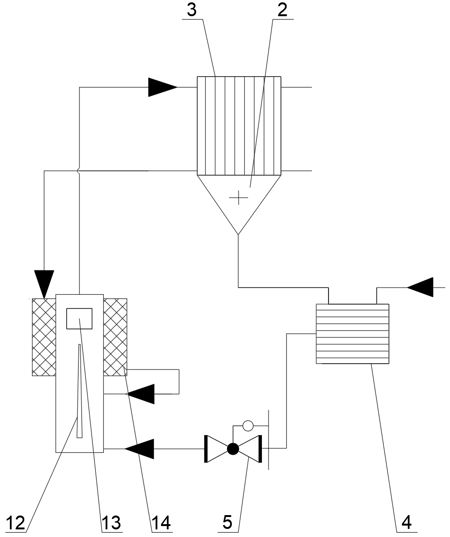

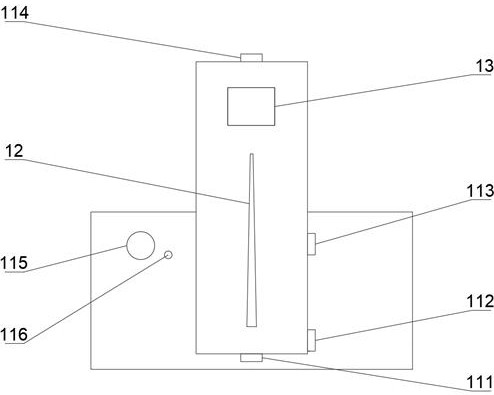

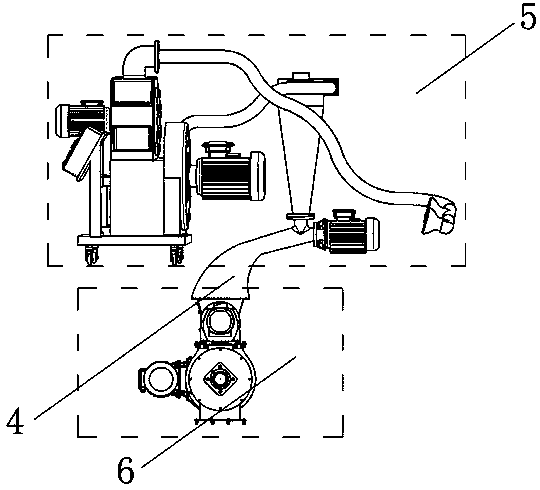

Method and system for regulating water quality of pool complex culture

InactiveCN101642076BGive full play to the biological roleLow costPisciculture and aquariaMultistage water/sewage treatmentInlet channelExpanded clay aggregate

The invention relates to a method and a system of pool culture. The method for regulating water quality of pool complex culture comprises the following steps: the water body discharged from a fish pool (1) inflows into an ecological crab pool (3) after being treated by a biological purifying channel (2), the water body inflows into a water body purifying equipment of clay and ceramsite (4) by power after purifying treatment in the ecological crab pool (3) and finally refluxes into the fish pool (1). The system for regulating water quality of pool complex culture comprises the following steps:arraying a plurality of fish pools (1) and crab pools (3) in a way of juxtaposition with one side provided with a biological purifying channel (2) and the other side is provided with the water body purifying equipment of clay and ceramsite (4); communicating the fish pools (1), the biological purifying channel (2) and the ecological crab pool (3) subsequently through a cannula device (5), wherein, the ecological crab pool (3) is connected with the water body purifying equipment of clay and ceramsite (4) through a water pump (6), the water body purifying equipment of clay and ceramsite (4) is connected with the fish pool (1) through an inlet channel (7). The invention is the culturing method for regulating complex water quality, which has the characteristics of low cost, low energy consumption and high efficiency and conforms to the pool culturing model of ecological principle.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

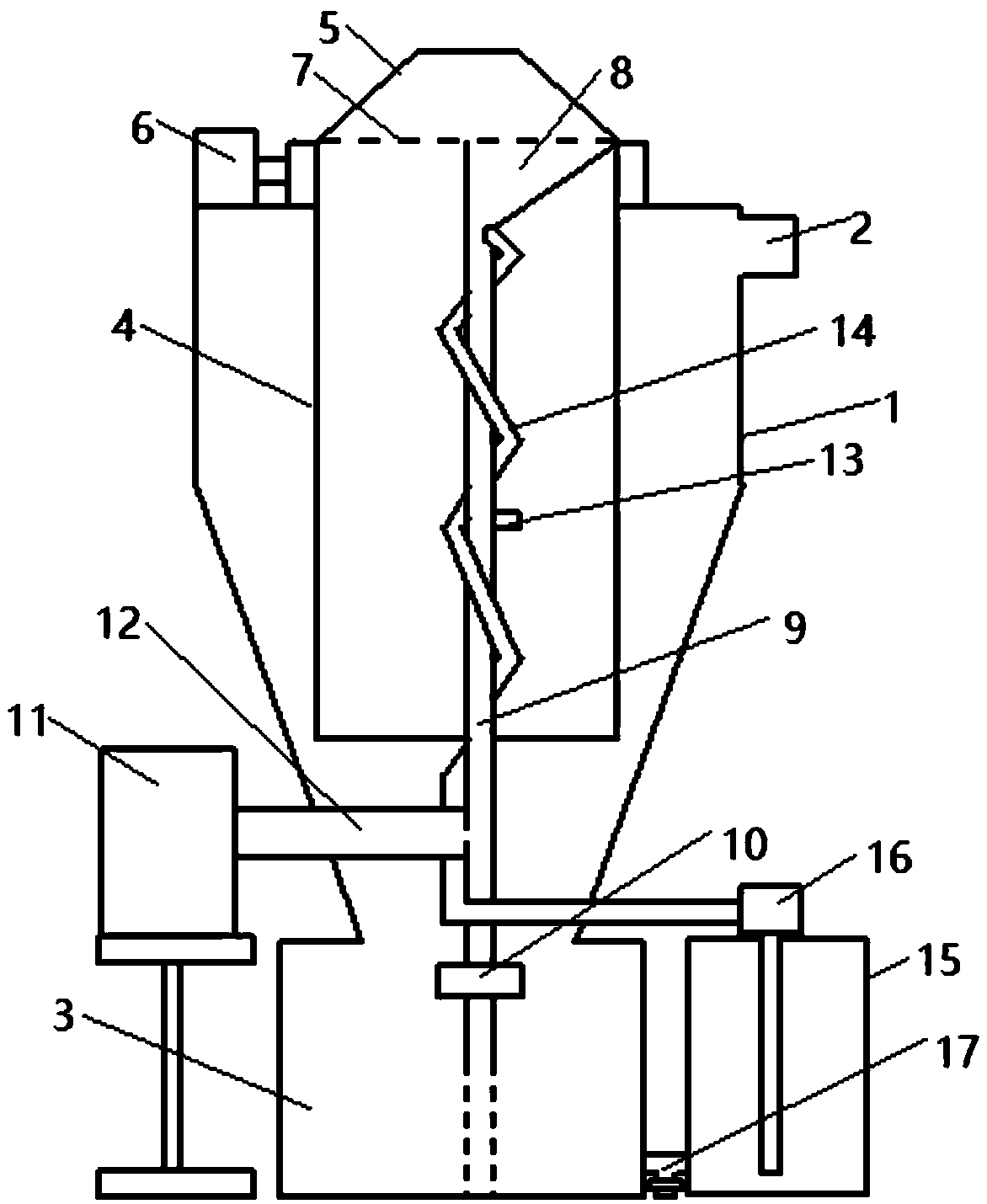

Efficient cyclone dust removal device and dust removal method thereof

The invention discloses an efficient cyclone dust removal device. The efficient cyclone dust removal device comprises an outer shell, an inner shell and a secondary dust removal assembly; the upper part of the inner shell protrudes outside the outer shell and is rotatably connected with the outer shell, the inner shell is driven to rotate by a double-way motor through a driving piece, and the upper edge of the inner shell shrinks upwards and inwards to form an opening of a cone frustum; the secondary dust removal assembly comprises a dust removal net, a net cleaning groove, a dust pipe, an exhaust fan, a dust detector and a controller; the dust removal net is horizontally arranged on the upper part of the inner shell; the net cleaning groove is formed below the dust removal net, and the top of the net cleaning groove is provided with an opening in contact with the dust removal net; the dust pipe is arranged below the net cleaning groove and connected with the bottom of the net cleaninggroove, and an electromagnetic valve is arranged on the lower part of the dust pipe; an air inlet of the exhaust fan is communicated with the dust pipe, located above the electromagnetic valve, through an air inlet pipe; the dust detector is arranged in the inner shell; and the controller is arranged on the outer shell, and electrically connected with the double-way motor, the electromagnetic valve and the exhaust fan. The invention further provides a dust removal method of the efficient cyclone dust removal device. The efficient cyclone dust removal device has the advantages that the effecton removing particles with the small grain sizes is good, and the dust removal efficiency is high.

Owner:施秀英

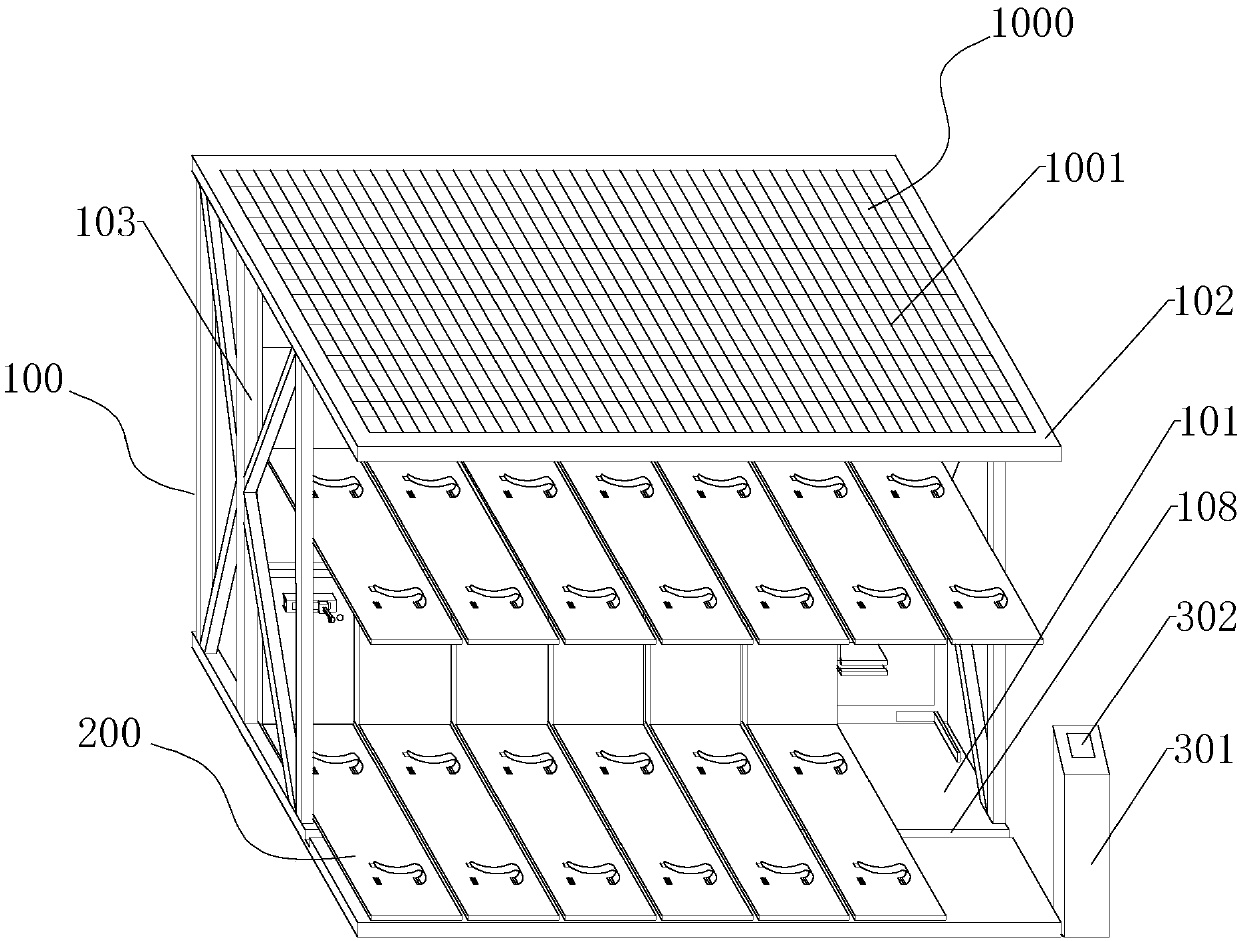

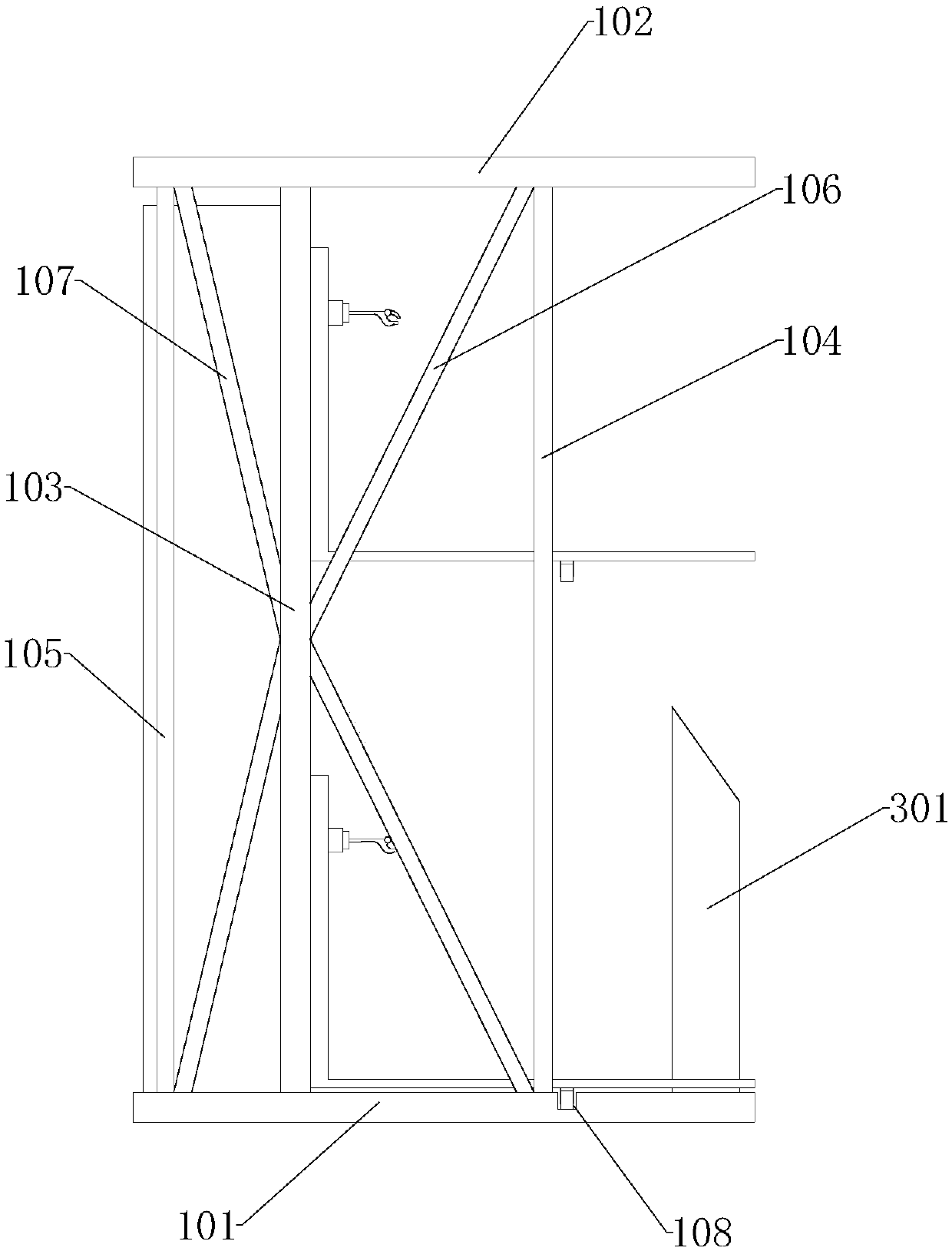

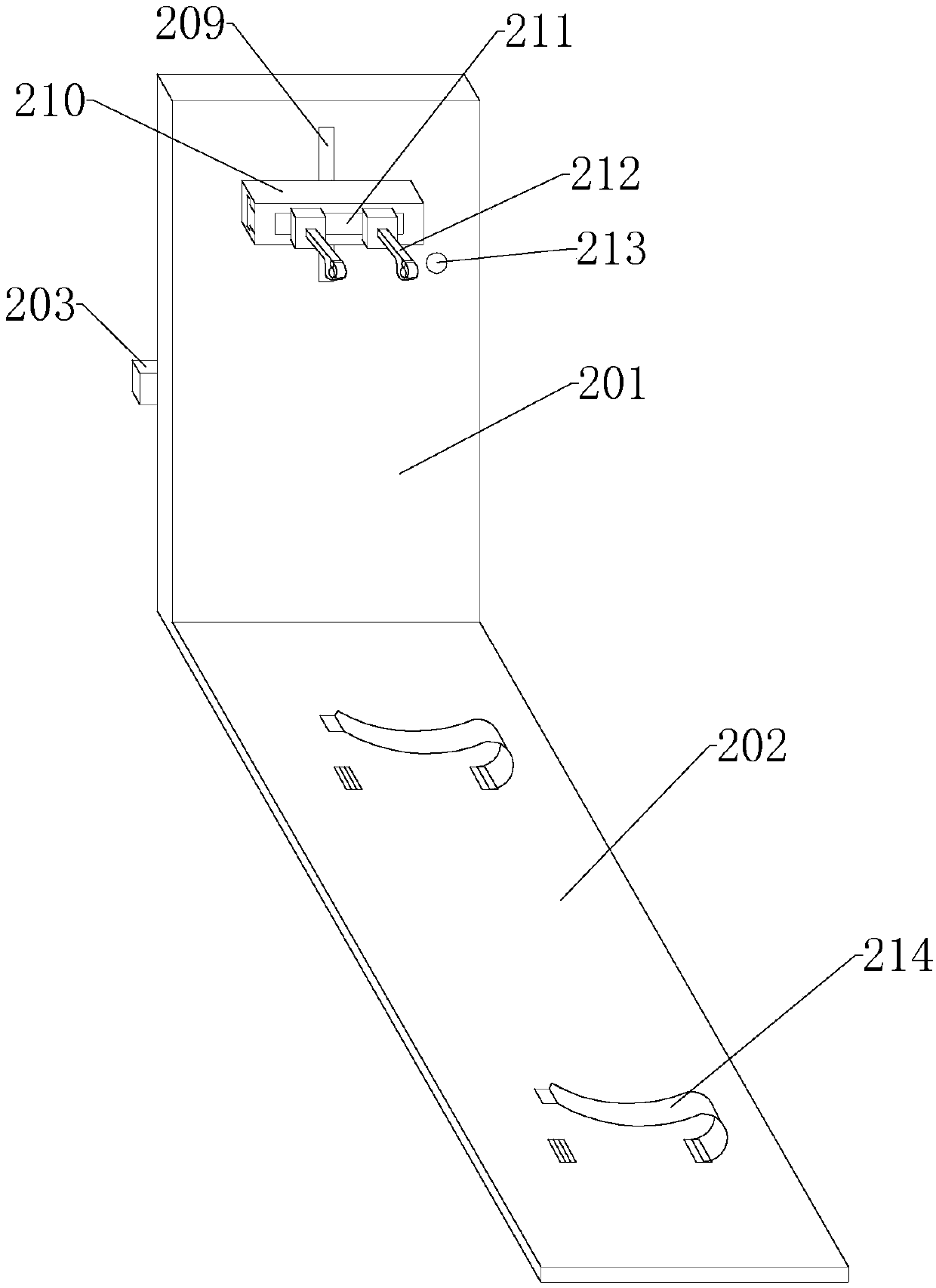

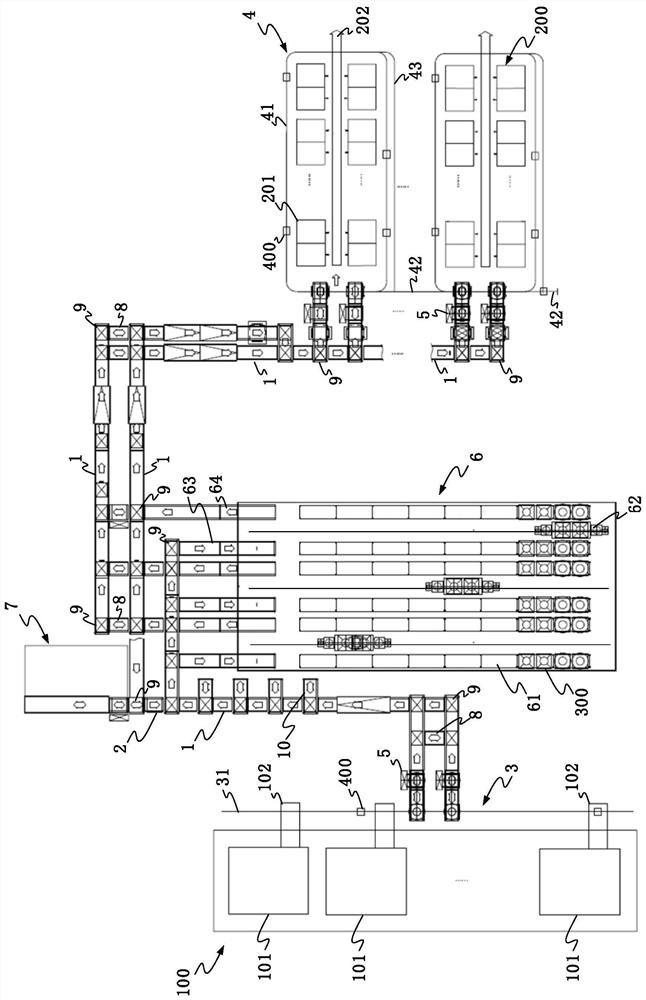

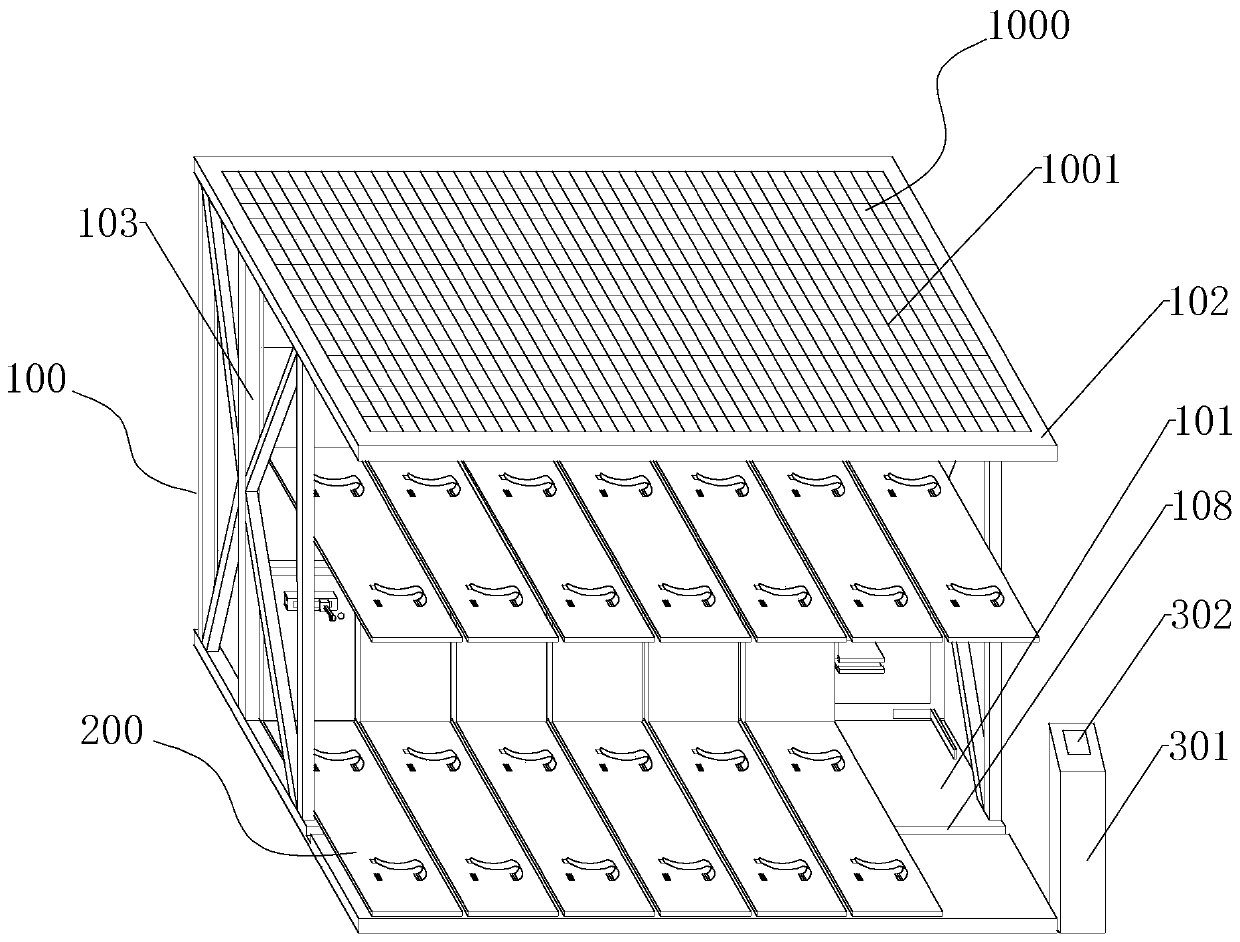

Multifunctional stereo parking shed for non-maneuverable electric vehicles

ActiveCN108678457AImprove space utilizationReduce land costParkingsAutomotive engineeringElectric vehicle

The invention discloses a multifunctional stereo parking shed for non-maneuverable electric vehicles. The multifunctional stereo parking shed comprises a shed body, a central vertical plate is arranged inside the shed body, and multiple parking plates are installed on the front side face of the central vertical plate horizontally side by side, and divided into two upper and lower layers; a controlcenter is arranged on the rear side of the central vertical plate, and connected with an upper transverse driving mechanism, a lower transverse driving mechanism, a longitudinal lifting mechanism, alongitudinal falling-back mechanism, an upper auxiliary pushing mechanism and a lower auxiliary pushing mechanism. The lower transverse driving mechanism drives the parking plates on the lower layer to move horizontally, and delivers the parking plates at one end into the longitudinal lifting mechanism, the longitudinal lifting mechanism carries the parking plates to ascend, the parking plates arehorizontally pushed into one end of the upper transverse driving mechanism through the upper auxiliary pushing mechanism, the upper transverse driving mechanism drives the parking plates on the upperlayer to move horizontally in the reverse direction and delivers the parking plates at the other end into the longitudinal falling-back mechanism, the longitudinal falling-back mechanism carries theparking plates to return to the part at the height of the lower layer, the lower auxiliary pushing mechanism horizontally pushes the parking plates into the other end of the lower transverse driving mechanism, and therefore circulating operation of the parking plates is realized.

Owner:FUJIAN UNIV OF TECH

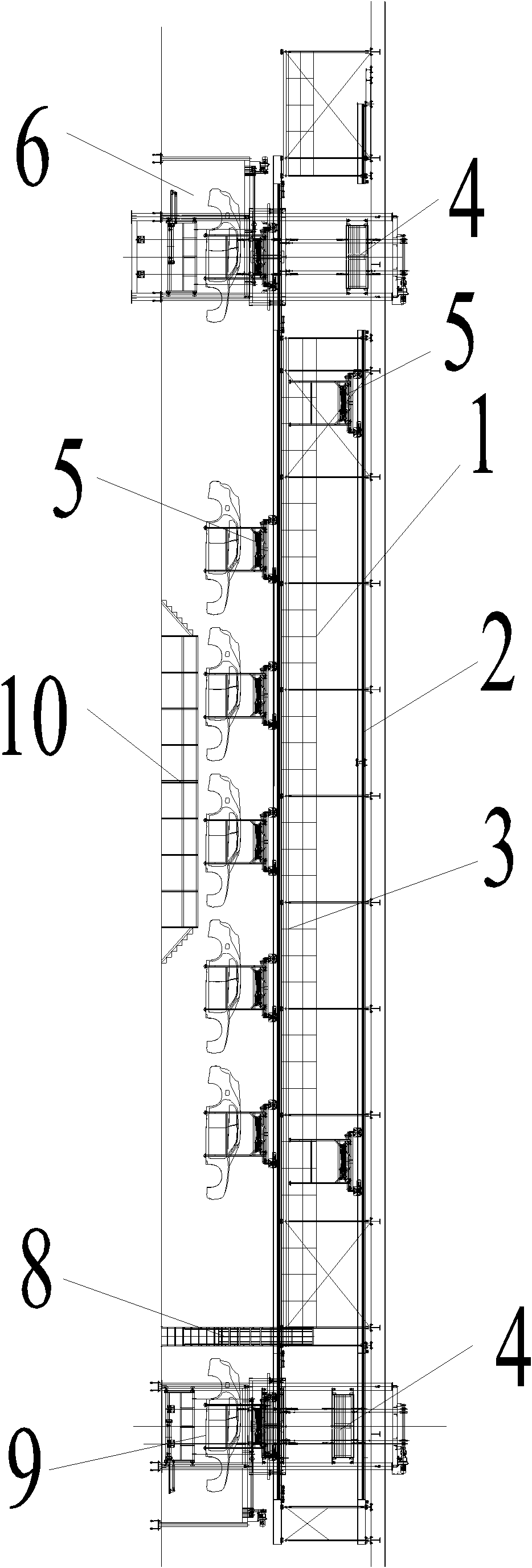

Tire blank conveying system and conveying method thereof

ActiveCN112693832AAvoid stagnationRealize cycle operationTyresConveyor partsDelivery systemTransfer line

The invention belongs to the technical field of tire production, and discloses a tire blank conveying system and a conveying method thereof. The tire blank conveying system can convey trays between a forming station and a vulcanizing station so as to convey tire blanks through trays, and comprises a conveying line and a return line which are arranged in a closed-loop manner so as to convey the trays in a circulating manner, a first carrying device, a second carrying device and a circulation library. The first carrying device is configured to carry the tire blanks output by the forming station to empty trays supplied by the return line; the second carrying device is configured to carry the tire blanks supplied by the conveying line to the vulcanizing station; the circulation library is configured to store and output the trays which are conveyed by the conveying line and carry the tire blanks so as to adjust the number of the trays on the conveying line; and the circulation library is further configured to store and output the empty trays conveyed by the return line so as to adjust the number of the trays on the return line. The tire blank conveying system can circularly convey the trays and adjust the number of the trays circulating in the tire blank conveying system in real time so as to be matched with the working efficiency of the forming station and the working efficiency of the vulcanizing station.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

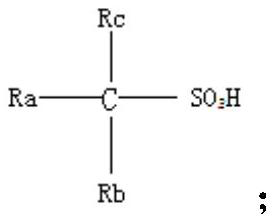

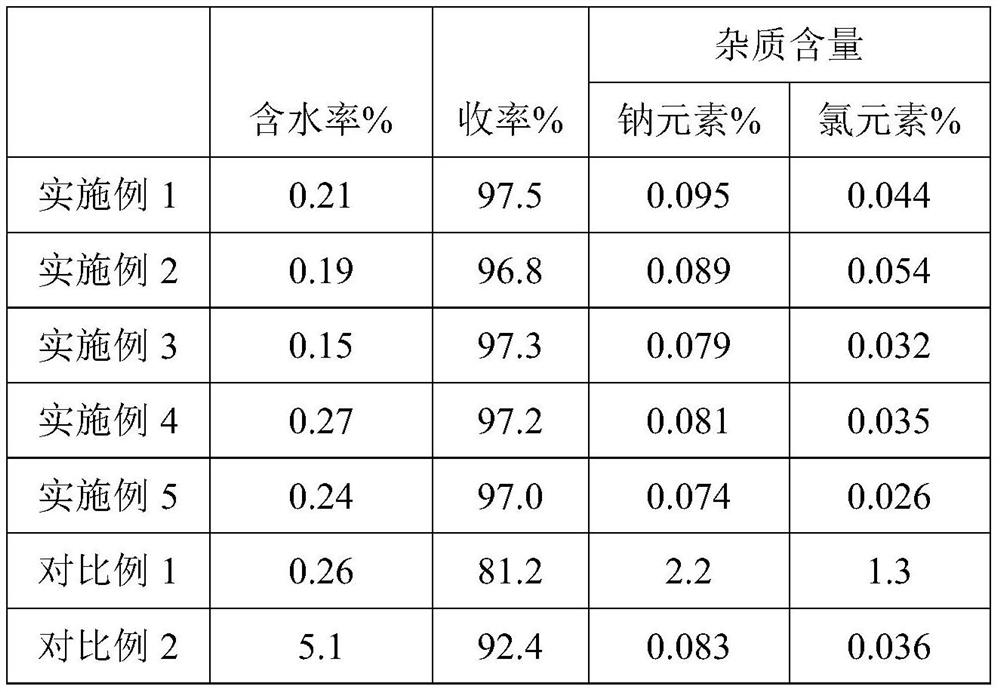

Preparation method and application of organic sulfonic acid

ActiveCN113666850AEfficient separationHigh reaction yieldSulfonic acids salts preparationSulfonic acid preparationAlkaneOrganic sulfonic acid

The invention relates to the technical field of fine chemicals, in particular to a preparation method and application of organic sulfonic acid. The preparation method of the organic sulfonic acid comprises the following specific steps: S1, preparing organic sulfonate; S2, reacting the organic sulfonate with a proton donor to obtain an organic sulfonic acid crude product; and S3, purifying the organic sulfonic acid crude product to obtain a finished product. The organic sulfonic acid obtained by the invention has the following advantages that (1) a gaseous proton provider is adopted, so that the production efficiency in the actual reaction process is improved while a polyhydroxy alkane sulfonic acid product with high reaction yield is obtained; (2) processing and purifying are performed by adopting enamel film evaporation and short-path molecular distillation equipment, and acidic byproducts and water in liquid components of reaction products are effectively separated to obtain a polyhydroxy alkane sulfonic acid finished product with the moisture content as low as 0.3%; and (3) recovery of hydrochloric acid can be realized while the polyhydroxy alkane sulfonic acid is obtained in the purification and separation process, and industrial mass production of the polyhydroxy alkane sulfonic acid is realized.

Owner:厦门威亮光学涂层技术有限公司

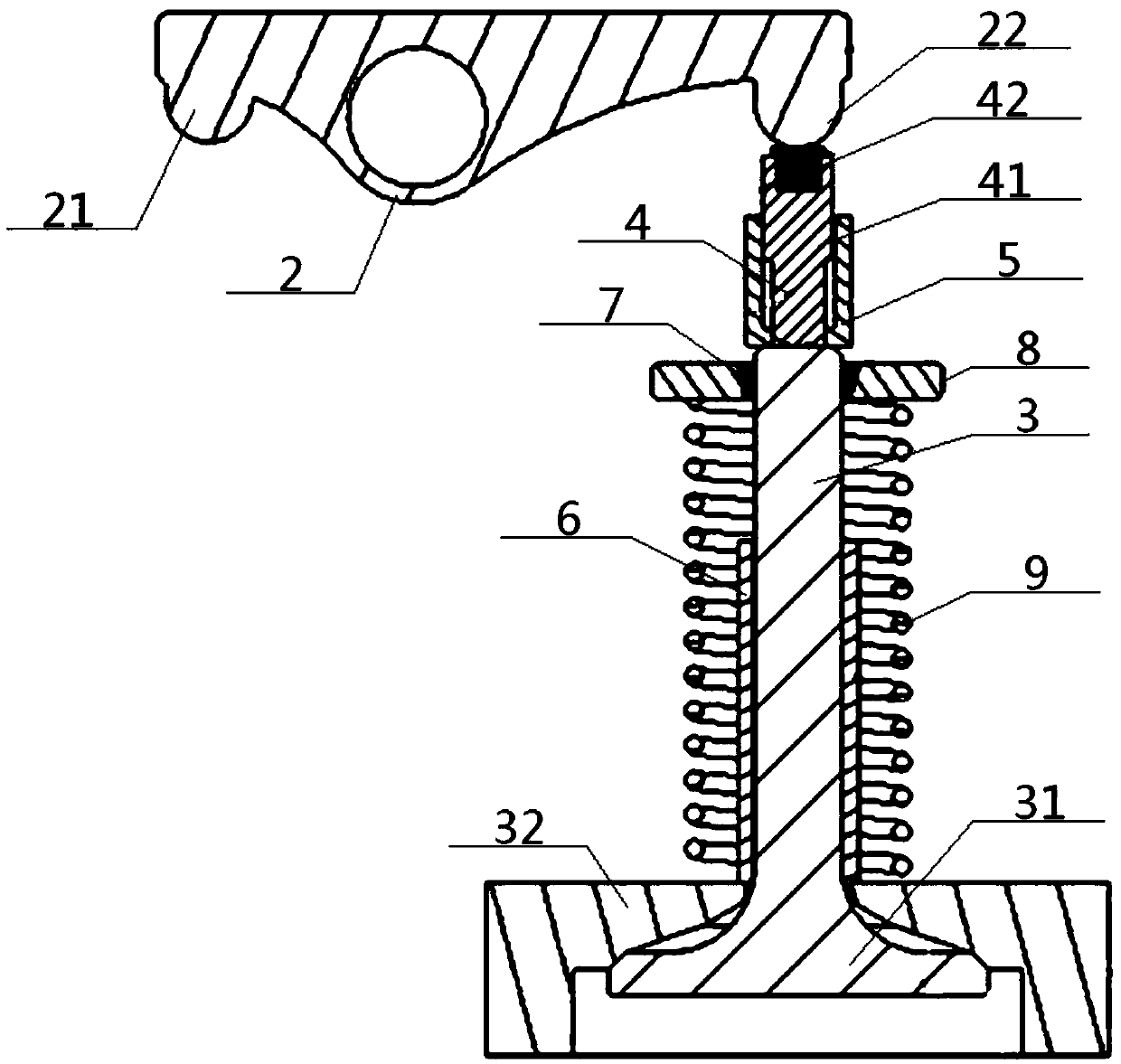

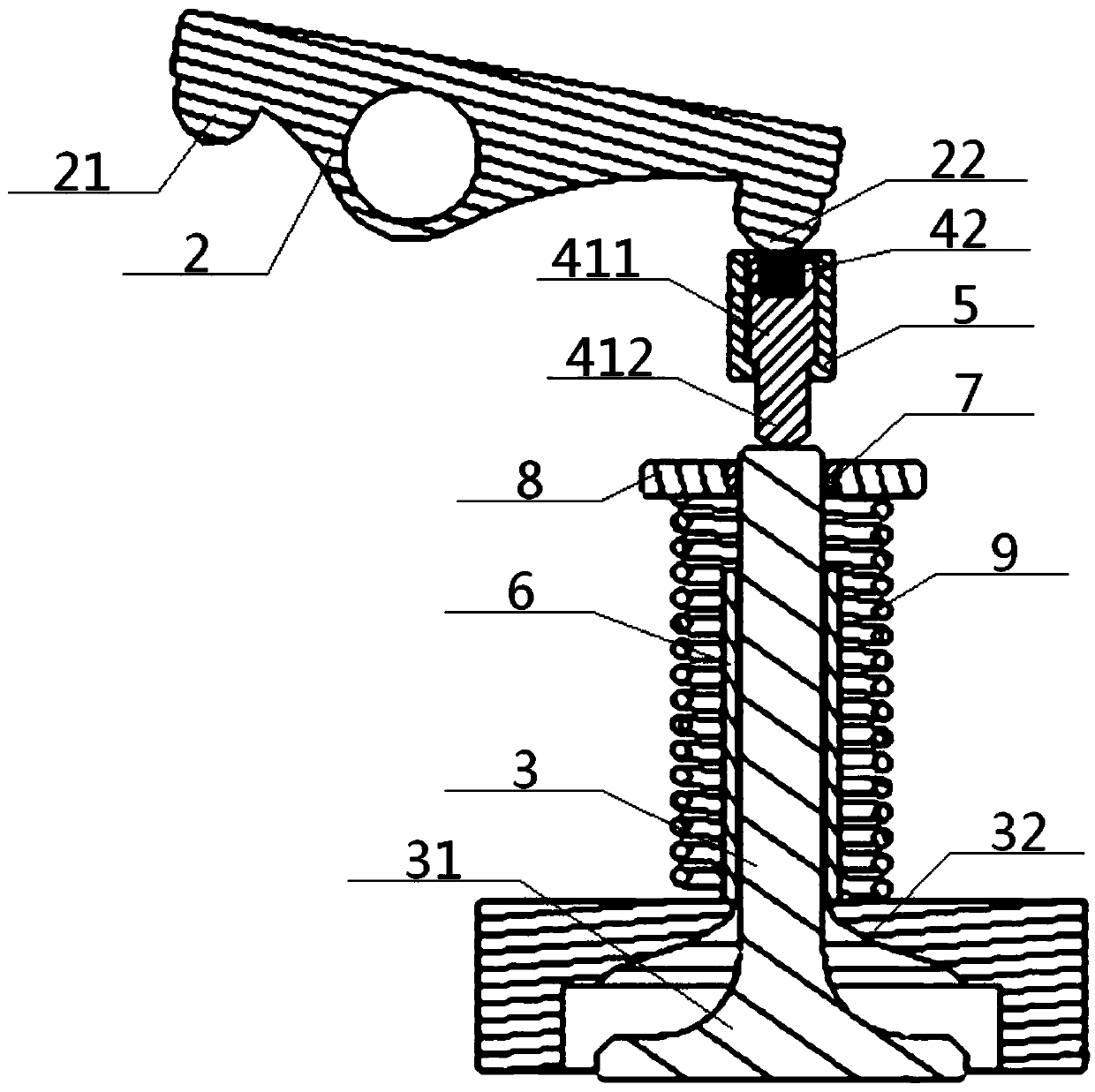

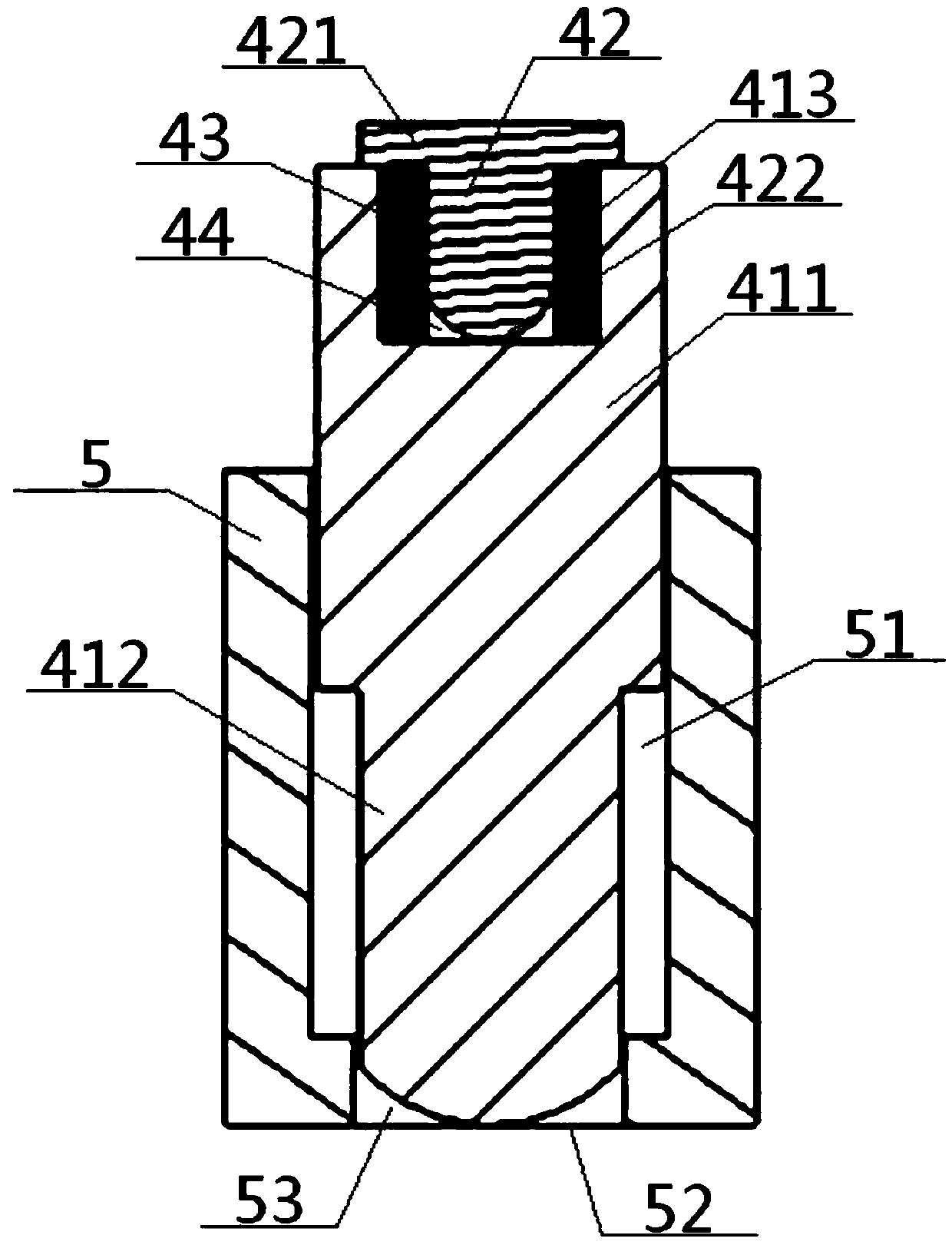

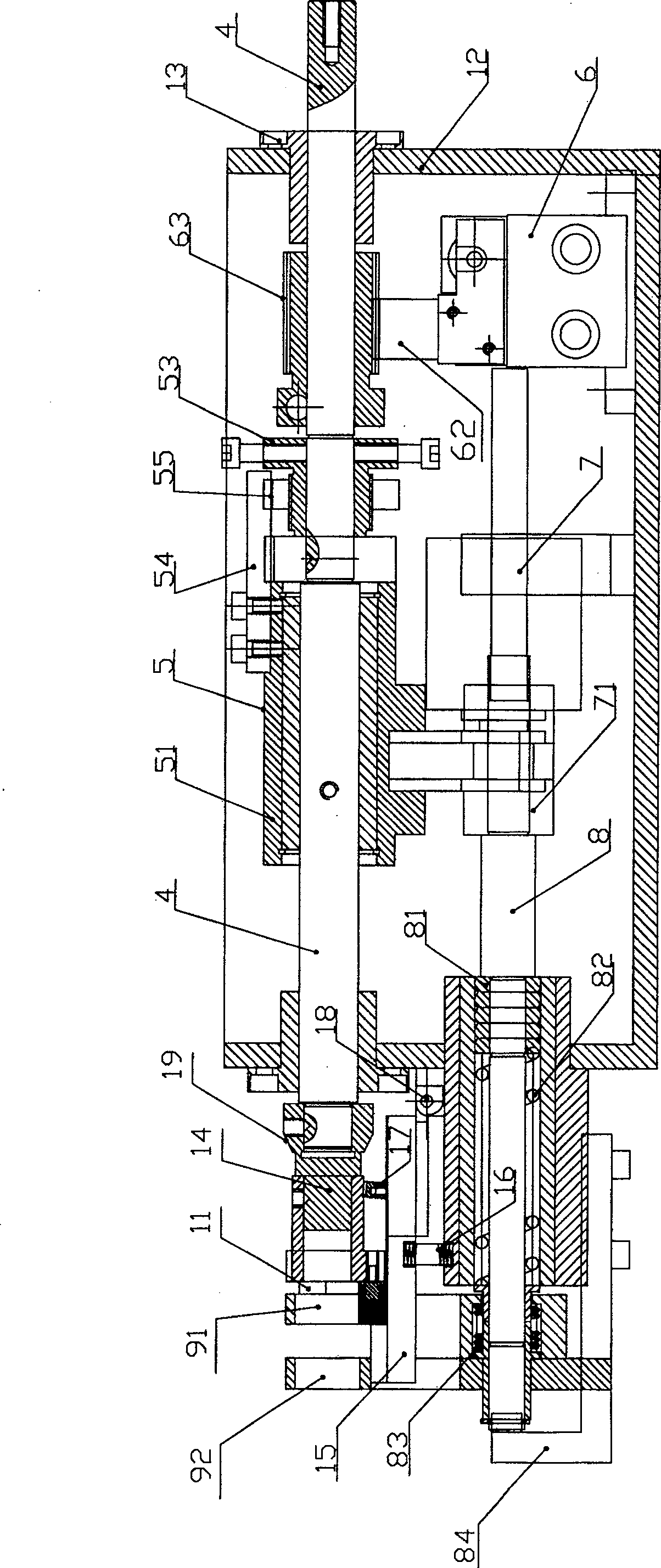

A thimble type anti-air valve eccentric wear gas distribution mechanism and its use method

ActiveCN106382138BAvoid partial wearLifting and moving smoothlyValve drivesMachines/enginesEngineeringRestoring force

An ejector pin type valve mechanism capable of preventing eccentric wear of an air valve comprises a rocker arm, a rotating shaft, an air valve rod, an air valve head, an ejector pin structure, a structure seat and an air valve guide, wherein the ejector pin mechanism comprises a pin valve body, a pin valve and an elastic material; the pin valve body comprises an upper valve body and a lower valve body; the outer end of the rocker arm is in jacking-up movement fit with a jacking device; the inner end of the rocker arm is in pressing-down movement fit with the air valve head via the ejector pin structure and the air valve rod; the air valve rod moves up and down along the air valve guide which sleeves the air valve rod; a spring seat and a spring are connected with the bottom of the structure seat to provide a restoring force for the air valve rod; and an external thread can be arranged on the outer wall of the air valve guide to hold lubricating oil. The ejector pin type valve mechanism can not only avoid eccentric wear of the air valve and improve the assembly efficiency, but also automatically realize cycle operation of the air valve rod and improve the transfer efficiency.

Owner:DONGFENG COMML VEHICLE CO LTD

Hydrogen flame ionization detector system with ultralow energy consumption and material consumption

The invention discloses a hydrogen flame ionization detector system with ultralow energy consumption and material consumption, and belongs to the technical field of gas chromatograph equipment. The detector system comprises a detector body, the detector body comprises a base, a nozzle, a collector, a catalytic oxidation reactor and a thermal insulation layer, the nozzle and the collector are arranged on the base, the collector is located above flame generated by the nozzle, the catalytic oxidation reactor and the base are integrally formed, the catalytic oxidation reactor is located on the outer side of the collector, the outer sides of the base and the catalytic oxidation reactor are sleeved with heat preservation layers, the detector body is used for being matched with the heat exchanger and the electrolysis reactor to detect sample gas to be detected, the base is used for installing the nozzle and the collector, and the nozzle is used for spraying out flames generated in the combustion process of hydrogen and combustion-supporting gas. Heat of tail gas of the detector body and liquefaction latent heat of water vapor in the tail gas are recovered through heat exchange, system energy consumption is reduced, and environment friendliness is achieved.

Owner:常州磐诺仪器有限公司

Leftover material recycling and granulating machine

InactiveCN110027132AAvoid pollutionImprove recycling effectPlastic recyclingEngineeringPulp and paper industry

The invention provides a leftover material recycling and granulating machine, and relates to the technical field of film manufacturing equipment. The leftover material recycling and granulating machine comprises an leftover material recycling assembly and a granulating assembly, wherein a communication pipeline is arranged between the leftover material recycling assembly and the granulating assembly; the leftover material recycling assembly comprises a main machine base; a crushing main cavity is formed at the top of the main machine base; a leftover material recycling pipe is arranged at theend of the crushing main cavity; a leftover material suction nozzle is arranged at the end of the leftover material recycling pipe; the granulating assembly comprises a screw main cavity; and the endof the screw main cavity is connected to one side of the leftover material recycling assembly with bolts through the communication pipeline. By adopting a negative pressure recycling system to recycleleftover materials in time, a better recycling effect is realized, and leftover material pollution is avoided; by connecting the recycling system and granulating equipment together, cyclic operationof the whole machine is realized; and by connecting equipment through communication pipelines, relatively good equipment connection adaptability is realized.

Owner:QINGDAO ZHENGDEXIANG IND & TRADE CO

Overhead conveying system of disassembly line for scrapped automobile

InactiveCN102530126BRealize cycle operationImprove dismantling efficiencyVehicle dissasembly recoverySolid waste disposalProgrammable logic controllerDelivery system

Owner:安徽韦尔汽车科技有限公司

A chip color detection device

ActiveCN114582765BRealize cycle operationImprove detection efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingComputer hardwareWafering

A chip color detection device disclosed by the invention comprises: a feeding module, a detection module and a feeding module which are sequentially arranged on the top of the detection device, and the feeding module includes a feeding conveying mechanism, a replenishing conveying mechanism and an upper feeding module. A material grabbing mechanism; a material feeding buffer mechanism is arranged on the feeding conveying mechanism, and the buffer pushing mechanism can push the wafer box on the feeding push chain into the buffer chamber for buffering; the detection module includes a detection support frame and a detection support frame arranged on the detection support At least one visual inspection mechanism on one side of the frame, the visual inspection mechanism can take pictures and test the wafer, and the inspection module also includes a marking mechanism. The wafers are sorted; a box conveying chain is arranged on one side of the unloading conveying mechanism, and a plurality of storage boxes are arranged on the box conveying chain, and the wafer box is pushed into the storage box by pushing the manipulator.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

A multifunctional three-dimensional parking shed for non-motorized electric vehicles

ActiveCN108678457BImprove space utilizationIncrease the number of parking spacesParkingsStructural engineeringElectric cars

The invention discloses a multifunctional stereo parking shed for non-maneuverable electric vehicles. The multifunctional stereo parking shed comprises a shed body, a central vertical plate is arranged inside the shed body, and multiple parking plates are installed on the front side face of the central vertical plate horizontally side by side, and divided into two upper and lower layers; a controlcenter is arranged on the rear side of the central vertical plate, and connected with an upper transverse driving mechanism, a lower transverse driving mechanism, a longitudinal lifting mechanism, alongitudinal falling-back mechanism, an upper auxiliary pushing mechanism and a lower auxiliary pushing mechanism. The lower transverse driving mechanism drives the parking plates on the lower layer to move horizontally, and delivers the parking plates at one end into the longitudinal lifting mechanism, the longitudinal lifting mechanism carries the parking plates to ascend, the parking plates arehorizontally pushed into one end of the upper transverse driving mechanism through the upper auxiliary pushing mechanism, the upper transverse driving mechanism drives the parking plates on the upperlayer to move horizontally in the reverse direction and delivers the parking plates at the other end into the longitudinal falling-back mechanism, the longitudinal falling-back mechanism carries theparking plates to return to the part at the height of the lower layer, the lower auxiliary pushing mechanism horizontally pushes the parking plates into the other end of the lower transverse driving mechanism, and therefore circulating operation of the parking plates is realized.

Owner:FUJIAN UNIV OF TECH

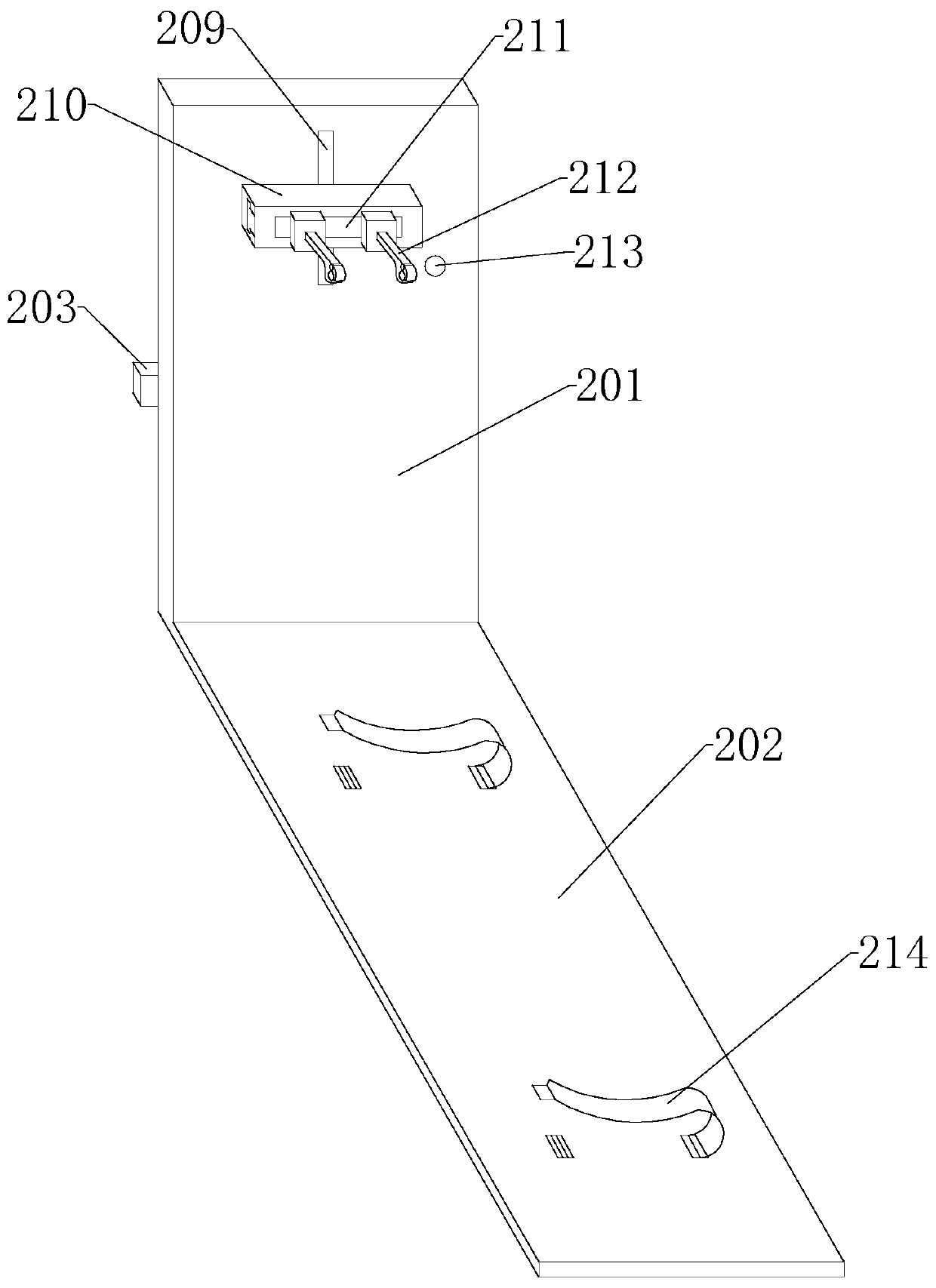

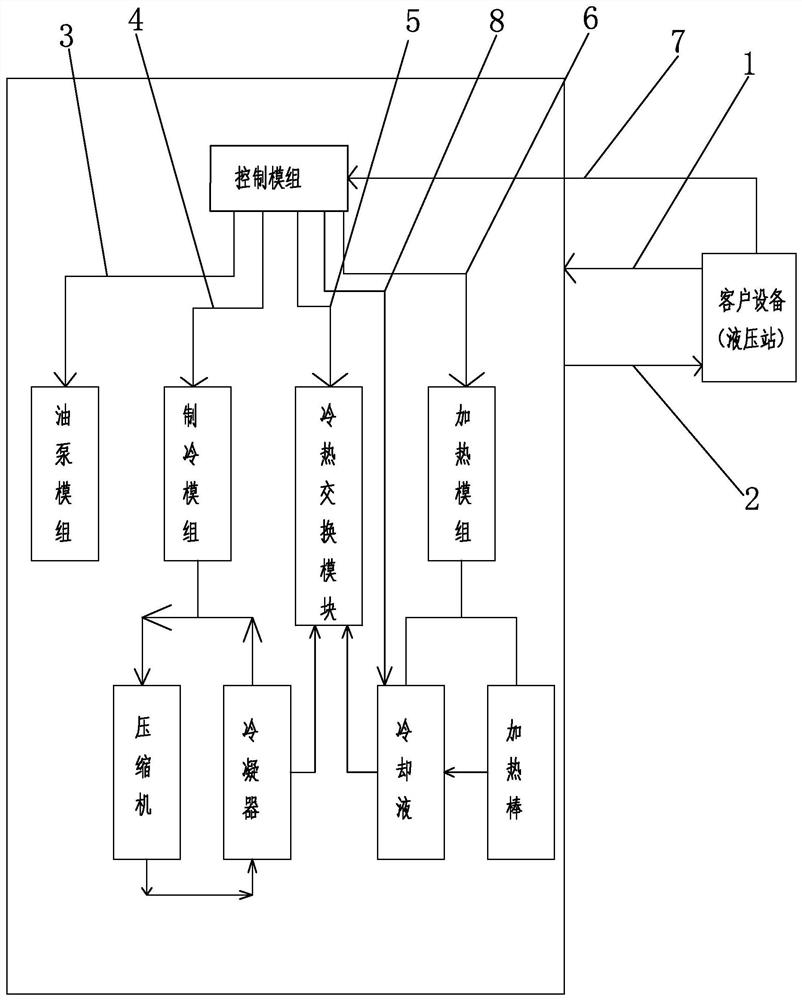

Oil temperature constant-temperature intelligent control system

ActiveCN112503061AImprove securityAvoid out-of-size situationsFluid-pressure actuator componentsTemperature controlEngineering

The invention discloses an oil temperature constant-temperature intelligent control system. The oil temperature constant-temperature intelligent control system involves a body, wherein the body comprises a control module, an oil pump operation module and a heating and refrigerating module, wherein the oil pump operation module is controlled by the control module to circulate pressure oil between ahydraulic station and the body; the heating and refrigerating module is used for heating or cooling the hydraulic oil inside the body; and the control module is used for detecting the temperature ofthe hydraulic oil inside the hydraulic station, controlling the heating and refrigerating module to heat or refrigerate the hydraulic oil inside the body according to the temperature for carrying outheating, cooling or constant-temperature control. According to the oil temperature constant-temperature intelligent control system, the control module is set, and the temperature of the hydraulic oilis detected in a specific time period, so that it is guaranteed that before production and machining, the oil is automatically heated to 40 DEG C, production does not need to wait, the shift production and production efficiency are improved, hydraulic pressure fluctuation is controlled, and the situations of product machining clamping deformation and excessive cutter feeding product size disqualification are avoided, so that the hydraulic pressure is stable, and the production requirement is met; and generation and scrap of defective products are reduced.

Owner:浙江盈亿机械股份有限公司

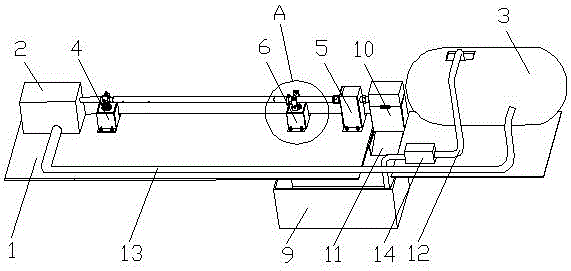

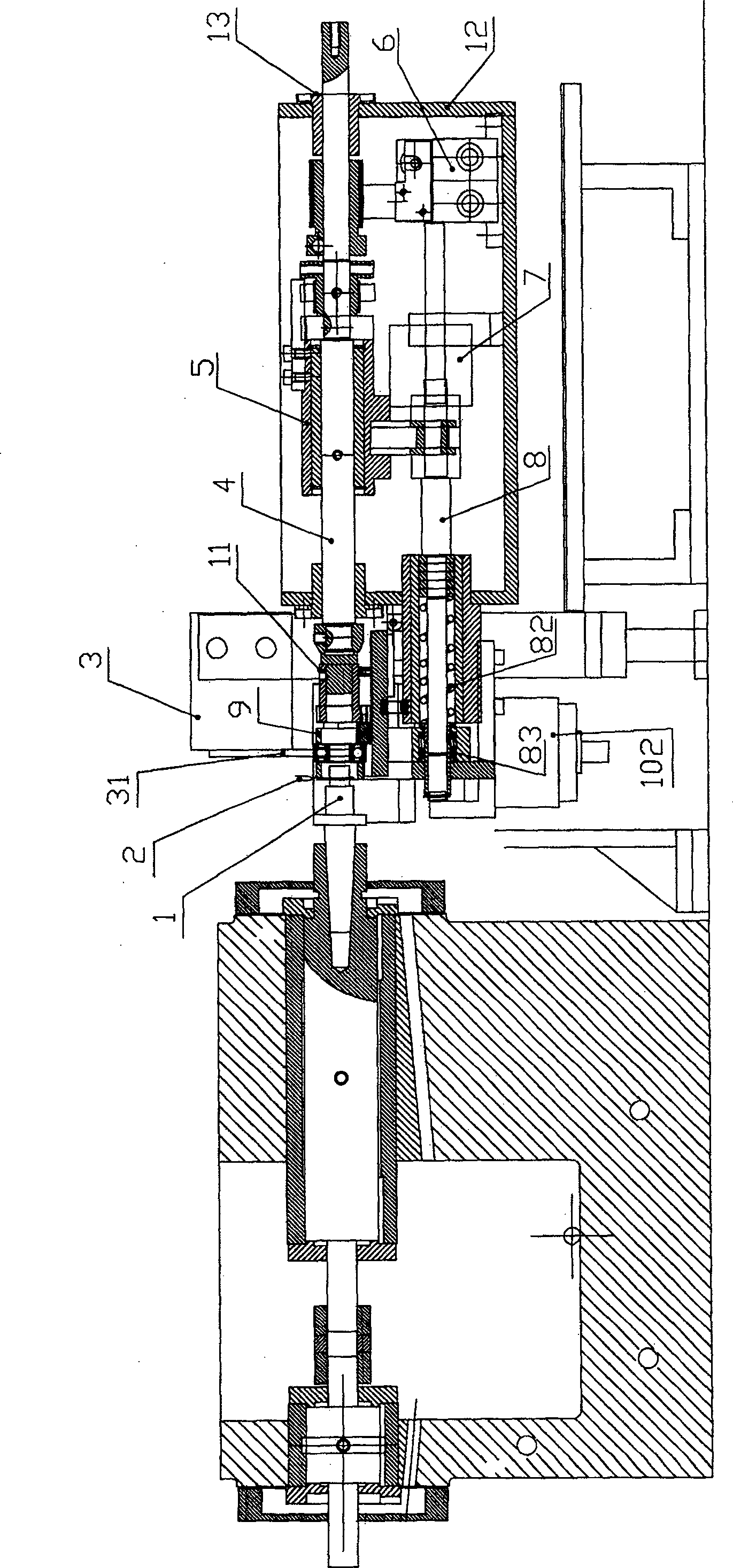

An indoor test platform for hydraulic oscillator

ActiveCN105258938BRealize cycle operationSimulate the realMachine part testingWater storage tankWorking environment

The invention discloses a hydraulic oscillator indoor testing platform, which belongs to the technical field of drilling tools. The hydraulic oscillator indoor testing platform comprises a mounting seat plate, a pump set and a water storage tank, and is characterized in that the mounting seat plate is connected with a clamping device and a pressurization device; the mounting seat plate is also connected with a sliding supporting device; the sliding supporting device is connected with a hitting force sensor; the outer round boss of the hydraulic oscillator is connected with a frequency sensor; a water collection groove is connected below the mounting seat plate and a water collection tank is connected below the mounting seat plate; the water collection tank and the water collection groove are connected via a diversion groove; a water inlet pipe and a water outlet pipe are arranged on the water storage tank; a water pump is connected onto the water inlet pipe; the water collection groove is connected with the water storage tank via the water inlet pipe; and the pump set is connected with the water storage tank via the water outlet pipe. The testing platform can clamp, fix and apply axial thrust to the hydraulic oscillator, the downhole working environment can be simulated truly, testing data errors can be reduced effectively, and the experimental data precision is higher after testing.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

A compression-stretching method for propellant with predetermined design size

ActiveCN107480388BEnable read analysisRealize cycle operationDesign optimisation/simulationSpecial data processing applicationsControl engineeringProcess engineering

Owner:XIAN MODERN CHEM RES INST

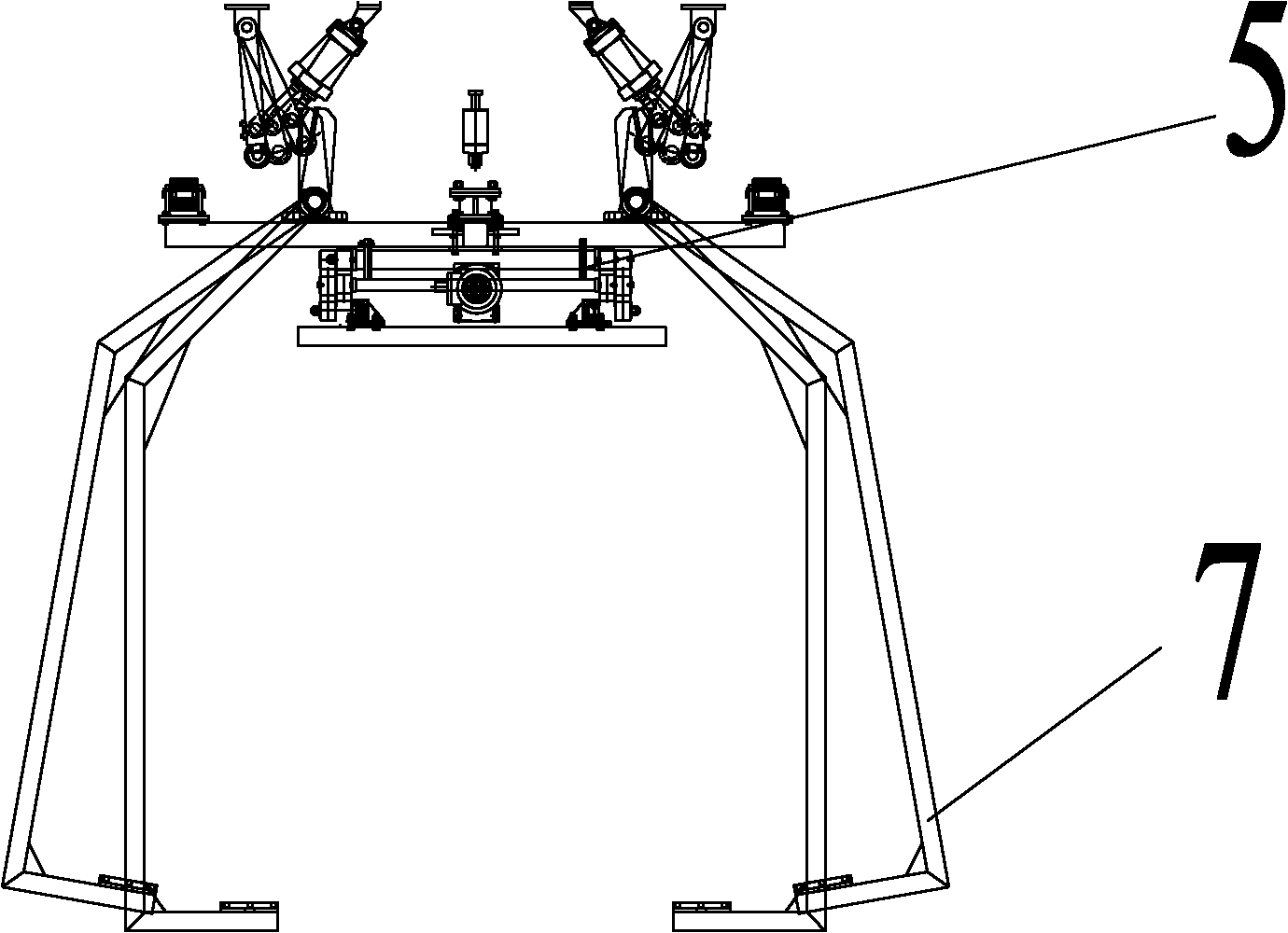

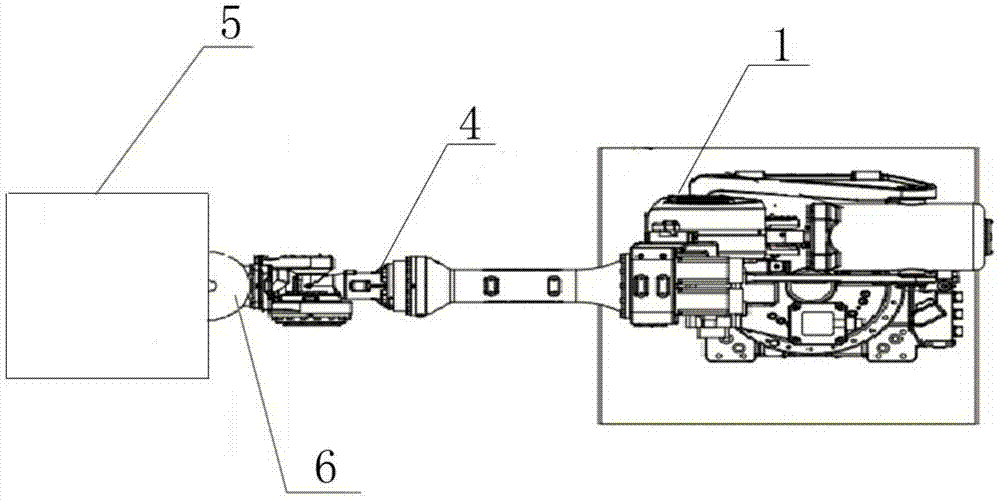

A continuous horizontal immersion coating system and method

ActiveCN105032718BFully automaticOvercoming the defect of severe uniformity deviationPretreated surfacesCoatingsCoating systemEngineering

The invention belongs to the technical field of film plating, and discloses a continuous horizontal dipping film coating system and a method. The continuous horizontal dipping film coating system comprises a robot, a robot control center and a circulating slide rail, wherein the robot and the robot control center are in signal connection; the robot is slidingly arranged on the circulating slide rail; the circulating slide rail is used for circularly sliding the robot; the robot is provided with an operation arm; multiple suckers for absorbing substrate base pieces are arranged at the front end of the operation arm; the robot drives the operation arm to act; and a film plating solution tank and a cleaning tank are formed beside the circulating slide rail. The system and the method integrate the dipping film plating, the cleaning and the drying as a whole, so that the defects of discontinuous procedures and long time consumption in the prior art are overcome, the full-automatic high-stability production of the dipping film plating with any area can be realized, the defect of severe uniformity deviation in upper, middle and lower areas of vertical pull dipping is overcome, and all points of horizontal dipping film plating are consistent, and the uniformity is excellent.

Owner:江西易晖光电科技有限公司

Circulating generator system

PendingCN111555587ARealize cycle operationImprove battery lifeDynamo-electric machinesAutomotive engineeringElectric energy

A circulating generator system relates to the technical field of engines, and comprises a battery pack, a starting motor, a generator and an electric device. The battery pack is linearly connected with the starting motor, the starting motor is in transmission connection with the generator through a belt or a gear, the generator is electrically connected with the electric device, and the generatoris further linearly connected with the battery pack. After the generator is started, the electric energy can be transmitted to a power operation system and can also be transmitted back to the startingmotor and the battery pack, so that the electric energy feedback in the using process is effectively guaranteed, the function of charging while using is achieved, and the battery pack can endurance for a long time.

Owner:汤英鹏

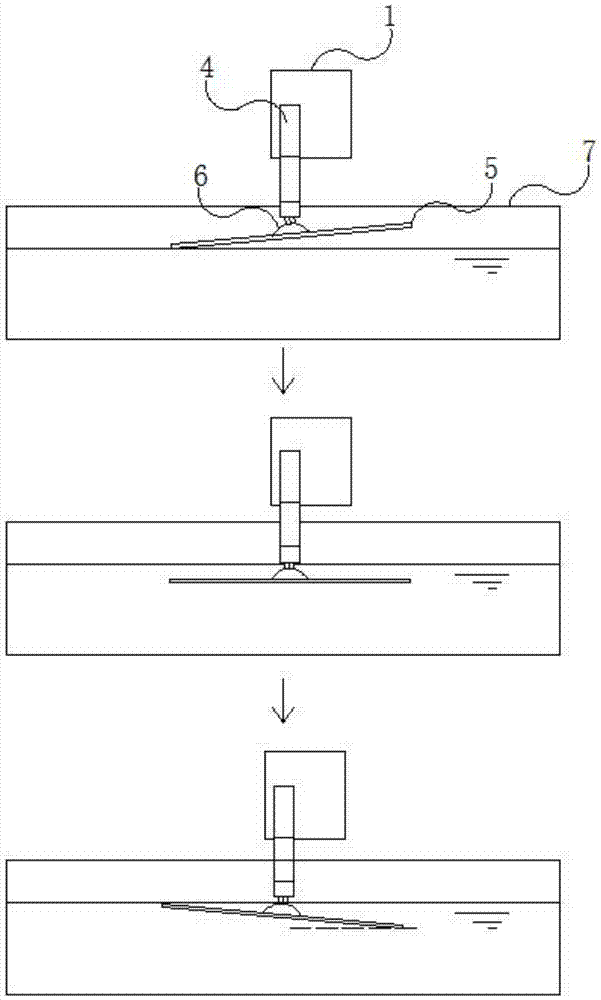

Cleaning device and method for cleaning industrially manufactured components

InactiveCN103167916BReduce consumptionRealize cycle operationGas treatmentRecuperative heat exchangersEngineeringCleansing Agents

In order to recover the resources (cleaning agent, heat) contained in the cleaning agent vapors suctioned off a cleaning system for cleaning industrially produced components, it is proposed to guide the suctioned-off waste air ({dot over (V)}ab) in a recovery device (5) through a heat register (9) of a refrigeration device (6) and thereby to heat it substantially to the temperature of the waste air ({dot over (V)}ab), and to supply the waste air ({dot over (V)}ab) heated and dried in this manner to the cleaning chamber (2) in the region of a bulkhead door (16) as preheated dried supply air ({dot over (V)}zu).

Owner:TMS TURNKEY MFG SOLUTIONS

A material clip conveying mechanism and electroplating equipment

ActiveCN105734653BRealize cycle operationAvoid corrosionElectrolysis componentsDrive wheelTransmission belt

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Double-side bearing vibration detector

InactiveCN100538306CRealize automatic feeding processSimple structureMachine bearings testingVibration testingControl systemBearing vibration

The invention relates to a bearing vibration detection device. Double-sided bearing vibration detection device, including rotating shaft, vibration detection contact, central control system, frame, bearing feeding device, bearing turning device, bearing conveying device, bearing sorting and discharging device and several sensors, sensors, vibration detection contact It is electrically connected with the central control system, and the central control system is electrically connected with the bearing feeding device, the bearing turning device, the bearing conveying device, and the bearing sorting and discharging device respectively. The bearing feeding device includes 2 jacking shafts, a driving cylinder and 2 feeding channels. Through the above technical solutions, the bearing vibration detection device of the present invention realizes the technical purpose of double-sided detection, and at the same time, the bearing feeding device has a simple structure and high detection efficiency.

Owner:宁波新荣基投资有限公司

A continuous transport system for steel wire rope traction rail mine cars

ActiveCN104670245BRealize cycle operationAvoid the problem of excessive turning radiusTramway railsRope railwaysTraction systemEngineering

The invention discloses a steel wire rope dragged rail tramcar continuous conveying system which comprises a steel wire rope traction system and a rail tramcar running system, wherein a steel wire rope driving device (1) is arranged at a horizontal outlet of a shaft mouth; a tail wheel (10) is fixed on a horizontal top plate of a shaft bottom; a tensioning device (12) is arranged at a horizontal roadway ground of the shaft bottom and is connected with the tail wheel (10); the upper end of a side dump tramcar (6) is connected with the steel wire rope (3) by a connecting device; the lower end of the side dump tramcar (6) is connected with a rail (8) through wheels; the rail (8) is composed of a loading / unloading place rail (13), a railway turnout (14), a bending rail (19) and a parallel rail (17); the up-going and down-going parallel rail (17) passes through the bending rail (19) and the railway turnout (14) to the loading / unloading place rail (13); car arresters (11) are respectively arranged at two ends of the loading / unloading place rail (13). The conveying procedure is performed automatically without human interference, the tramcar does not need to hook up and down, the loading and unloading time is shortened, and the downhole conveying efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com