An indoor test platform for hydraulic oscillator

A technology of hydraulic oscillator and test platform, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve the problems of experimental data error, decrease of test data accuracy, and poor flexibility of test experimental data operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

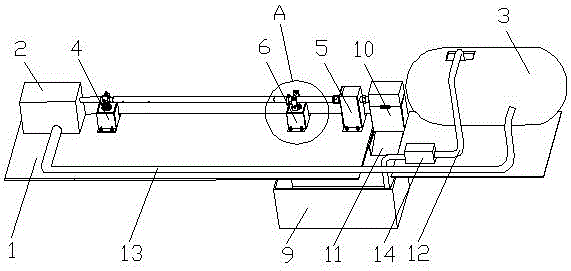

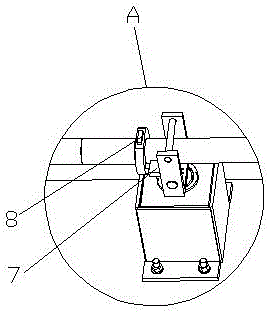

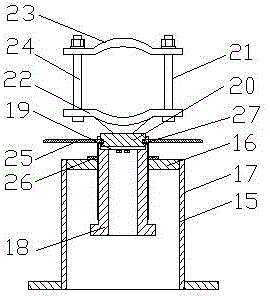

[0054] see figure 1 and figure 2 , a hydraulic oscillator indoor test platform, comprising a mounting base plate 1, a pump unit 2 fixed at one end of the mounting base plate 1 and a water storage tank 3 fixed at the other end of the mounting base plate 1, the mounting base plate 1 is connected to There is a clamping device 4 for clamping the hydraulic oscillator and a pressurizing device 5 for pressurizing the hydraulic oscillator, the clamping device 4 is close to the pump group 2, the pressurizing device 5 is close to the water storage tank 3, the A sliding support device 6 for sliding the hydraulic oscillator is also connected to the installation seat plate 1, the sliding support device 6 is located between the clamping device 4 and the pressurizing device 5, and the impact force sensor is connected to the sliding support device 6 7. A frequency sensor 8 is connected to the outer circular boss of the hydraulic oscillator, a water collection tank 9 is connected below the i...

Embodiment 2

[0057] see Figure 1-Figure 3 , a hydraulic oscillator indoor test platform, comprising a mounting base plate 1, a pump unit 2 fixed at one end of the mounting base plate 1 and a water storage tank 3 fixed at the other end of the mounting base plate 1, the mounting base plate 1 is connected to There is a clamping device 4 for clamping the hydraulic oscillator and a pressurizing device 5 for pressurizing the hydraulic oscillator, the clamping device 4 is close to the pump group 2, the pressurizing device 5 is close to the water storage tank 3, the A sliding support device 6 for sliding the hydraulic oscillator is also connected to the installation seat plate 1, the sliding support device 6 is located between the clamping device 4 and the pressurizing device 5, and the impact force sensor is connected to the sliding support device 6 7. A frequency sensor 8 is connected to the outer circular boss of the hydraulic oscillator, a water collection tank 9 is connected below the instal...

Embodiment 3

[0061] see Figure 1-Figure 3 , a hydraulic oscillator indoor test platform, comprising a mounting base plate 1, a pump unit 2 fixed at one end of the mounting base plate 1 and a water storage tank 3 fixed at the other end of the mounting base plate 1, the mounting base plate 1 is connected to There is a clamping device 4 for clamping the hydraulic oscillator and a pressurizing device 5 for pressurizing the hydraulic oscillator, the clamping device 4 is close to the pump group 2, the pressurizing device 5 is close to the water storage tank 3, the A sliding support device 6 for sliding the hydraulic oscillator is also connected to the installation seat plate 1, the sliding support device 6 is located between the clamping device 4 and the pressurizing device 5, and the impact force sensor is connected to the sliding support device 6 7. A frequency sensor 8 is connected to the outer circular boss of the hydraulic oscillator, a water collection tank 9 is connected below the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com