Double-side bearing vibration detector

A bearing vibration and detection device technology, which is applied in the direction of measuring device, vibration test, mechanical bearing test, etc., can solve the problem that the bearing quality cannot be comprehensively judged, and achieve the effect of simple structure and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

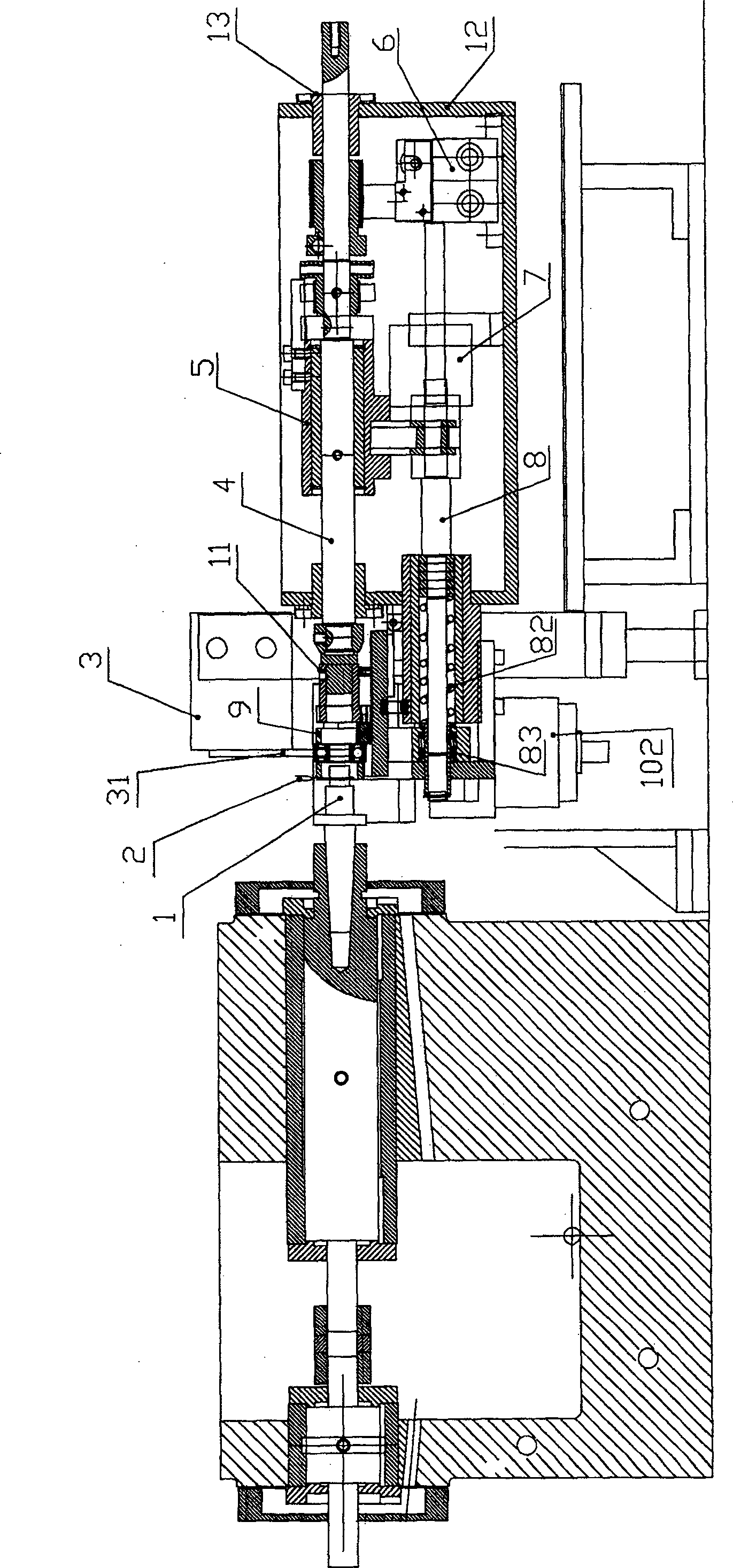

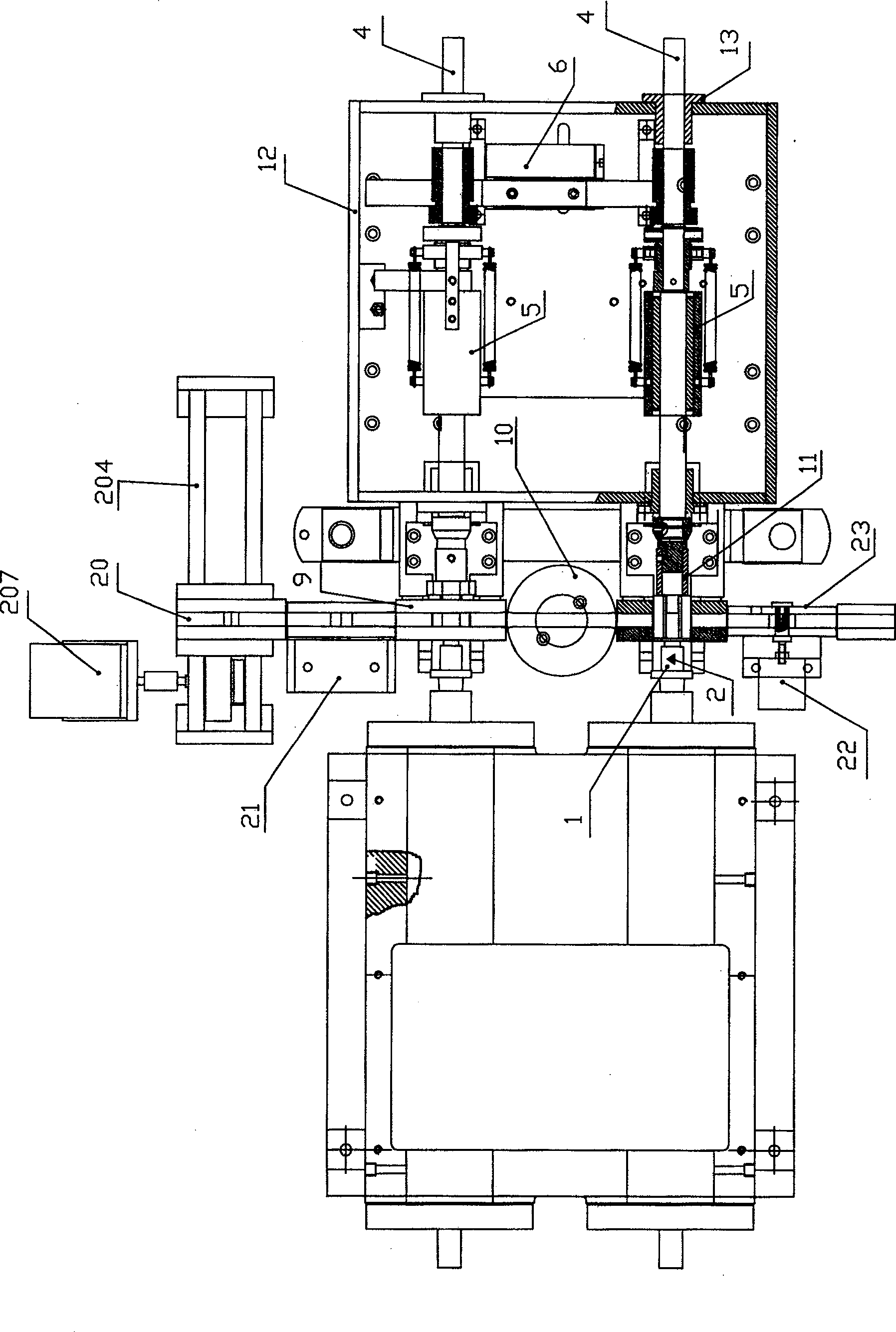

[0037] like figure 1 , figure 2 , Figure 15 The double-sided bearing vibration detection device shown includes a rotating shaft 1, a vibration detection contact 2, a central control system, a frame 12, a bearing feeding device, a bearing turning device, a bearing conveying device 3, a sorting and discharging device 20, and several sensors . The sensor and the vibration detection contact 2 are electrically connected to the central control system, and the central control system is electrically connected to the bearing feeding device, the bearing turning device, the bearing conveying device 3 and the sorting and discharging device 20 respectively.

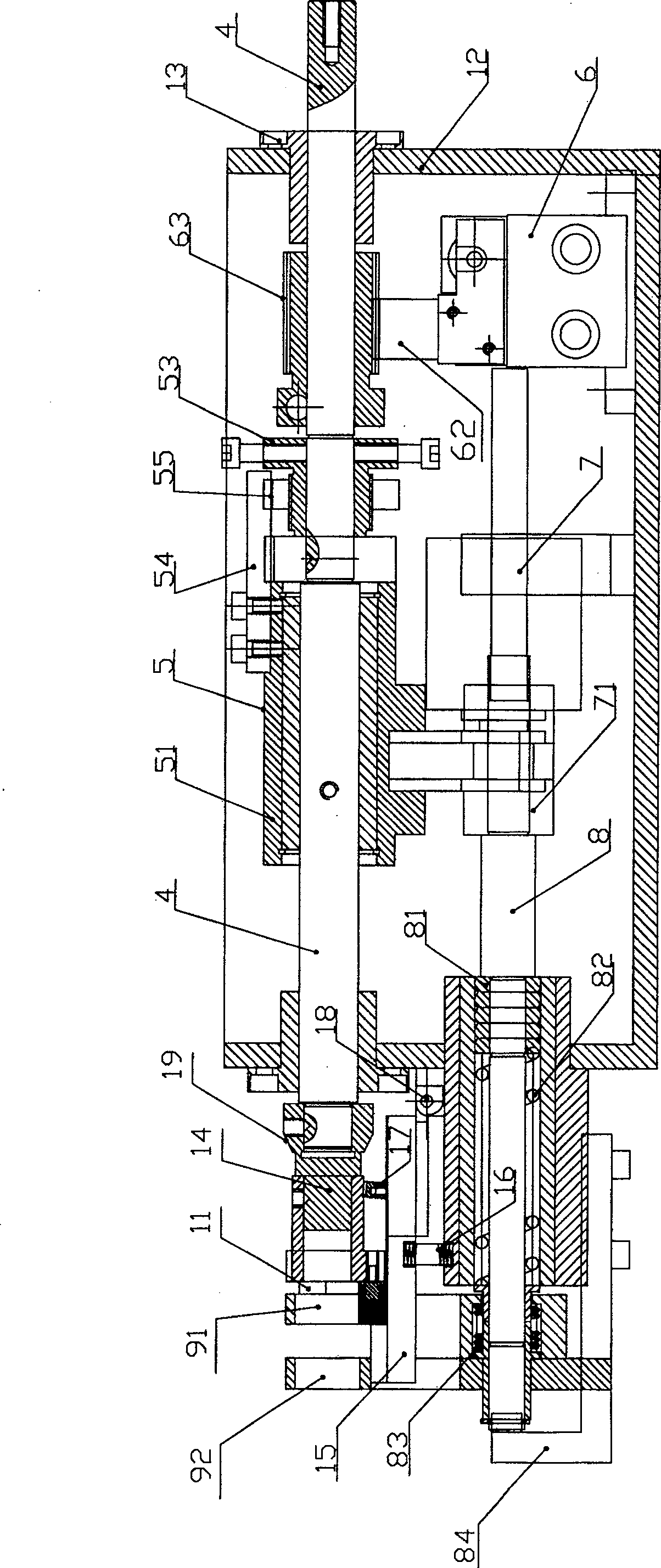

[0038] like image 3 , Figure 4 As shown, the bearing feeding device includes 2 jacking shafts 4, 1 driving cylinder 7, 2 pushing shafts 8 and 2 feeding channels 9. The 2 jacking shafts 4 are arranged in the bushing 13 on the frame 12, and the sensor 57 Set on top axis 4. The driving cylinder 7 is fixed on the frame 12, the d...

Embodiment 2

[0050] like Figure 9 , Figure 10 As shown, the rotating device includes a synchronous pulley A63' fixedly arranged on the top shaft 4, a motor 61' is arranged on the frame 12, and a synchronous pulley B64' is arranged on the output shaft of the motor 61', and the synchronous pulley A63' is connected with The timing pulley B64' is connected by the timing belt 62'. Other technical solutions of this embodiment are as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com