A material clip conveying mechanism and electroplating equipment

A conveying mechanism and material clip technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems that the deformation of the two conveyor belts cannot be guaranteed to be exactly the same, and the continuous production of thin plate electroplating cannot be realized, so as to achieve the effect of ensuring continuous normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

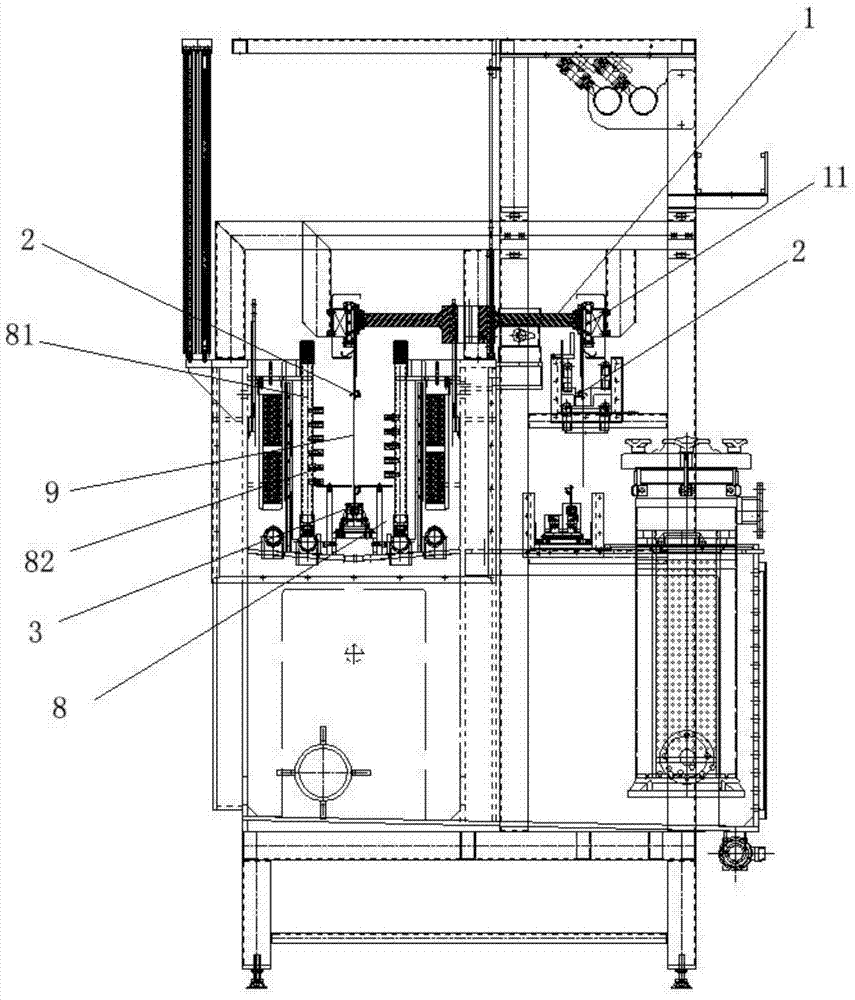

[0063] The present embodiment provides a kind of feed clip conveying mechanism, such as figure 1 shown, including,

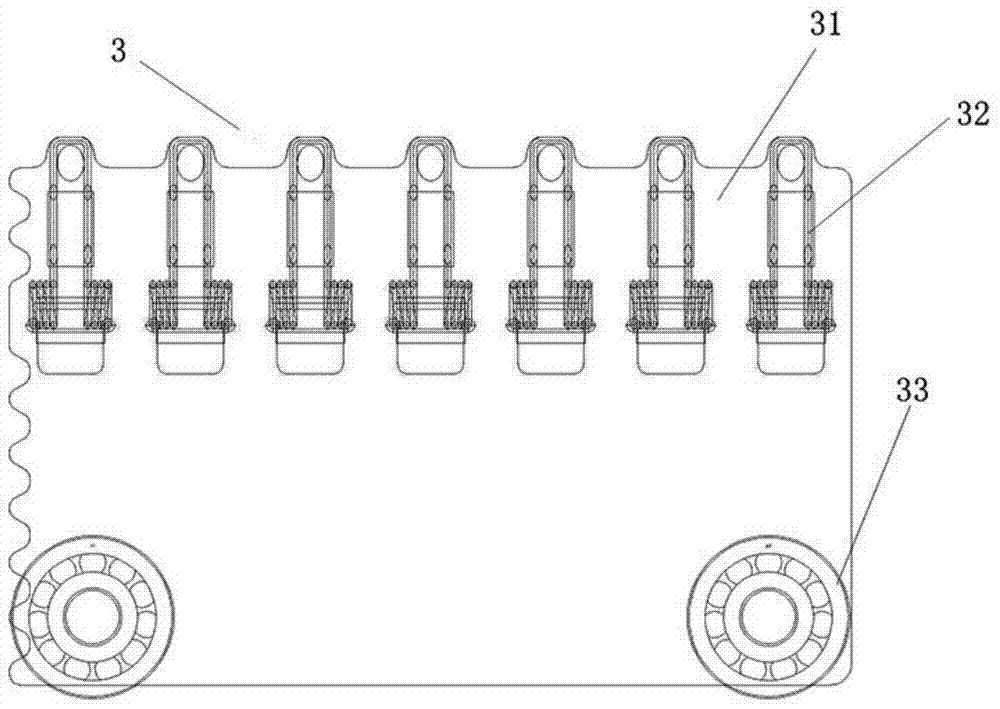

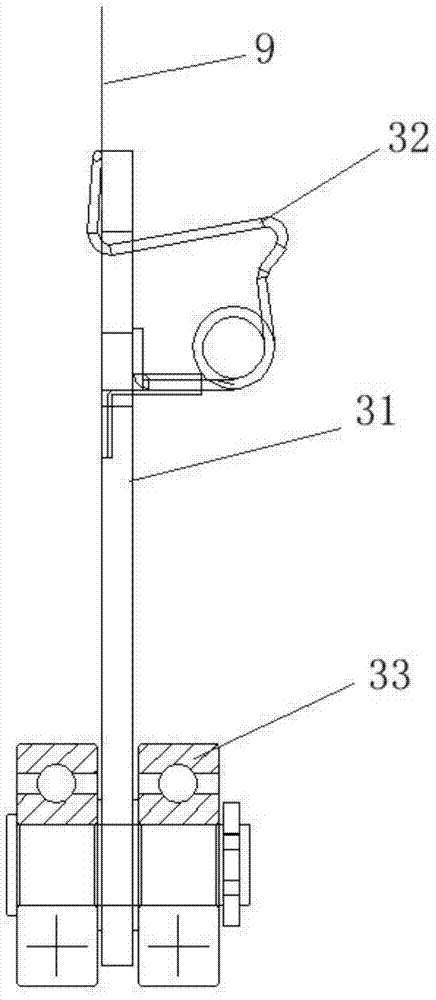

[0064] The circular track 4 is provided with a material clip 3 inside;

[0065] at least two transmission wheels 51;

[0066] The material clip transmission belt 53 is driven by the transmission wheel 51 and circulates; wherein

[0067] The clip conveying belt 53 includes a first part 53a located at the bottom or below the circular track 4 and a second part 53b away from the circular track 4, and the circular track 4 has a loop set corresponding to the first part 53a. The position part 4b and the electroplating part 4a away from the second part 53b, the clip can be driven by the first part 53a of the clip conveyor belt 53 in the return position of the circular track 4 Movement within section 4b.

[0068] The above-mentioned material clip conveying mechanism, the circular track 4 is used to limit the movement track of the material clip, and the material clip ...

Embodiment 2

[0101] A kind of electroplating equipment, such as figure 1 shown, including,

[0102] Feeding device, used to load the plates to be electroplated;

[0103] The unloading device is used to unload the plates that have been electroplated;

[0104] The electroplating tank 8 is located between the feeding device and the unloading device, and is used to form an electroplating layer on the plate to be electroplated when the plate to be electroplated passes through;

[0105] The clamp transmission belt 11 is located above the electroplating tank 8 and drives the clamps to circulate; and,

[0106] In the clip conveying mechanism described in Embodiment 1, the circular track 4 is arranged below the clamp conveyor belt 11, and the electroplating part of the circular track 4 is perpendicular to the plane where the clamp conveyor belt 11 is located. The projection coincides with the clamp transfer belt 11, the electroplating part 4a of the circular track 4 passes through the electropla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com