A continuous horizontal immersion coating system and method

A coating system, a horizontal technology, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the requirements of extremely strict appearance color consistency, unfavorable functional film uniformity preparation, uniformity requirements Extremely harsh and other problems, to achieve the effect of reducing the time spent on process operation and cleaning, solving the inability to achieve large-scale production, and overcoming the inconsistency of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

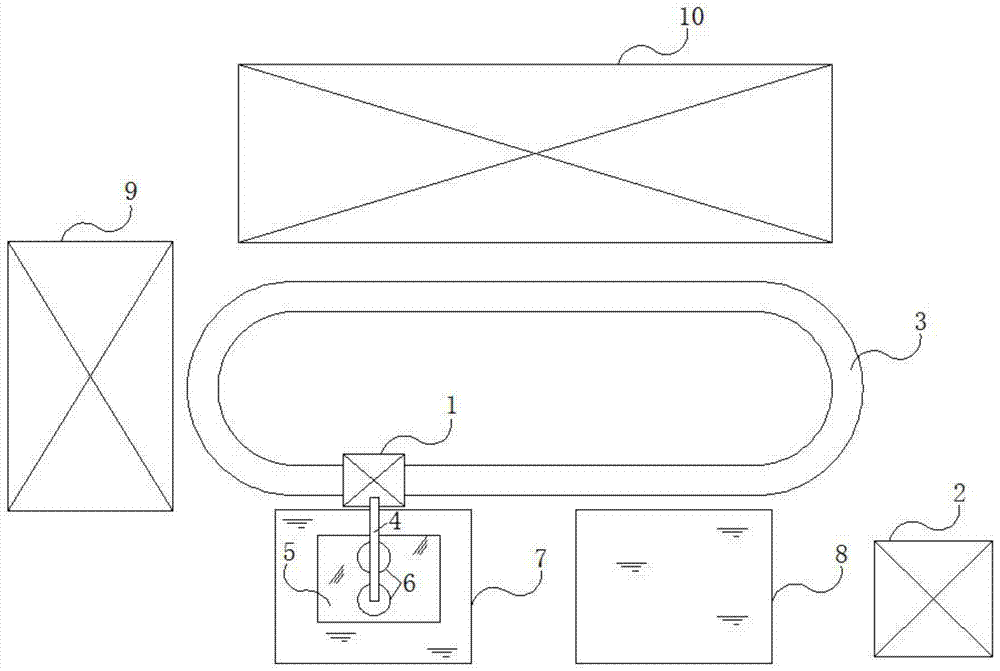

[0045] Such as figure 1 As shown, a continuous horizontal immersion coating system includes a robot 1, a robot control center 2 and a circulating slide rail 3, the robot 1 is connected to the robot control center 2 for signals, and the robot 1 is slidably arranged on the circulating slide rail 3, The circular slide rail 3 is used for the circular sliding of the robot 1;

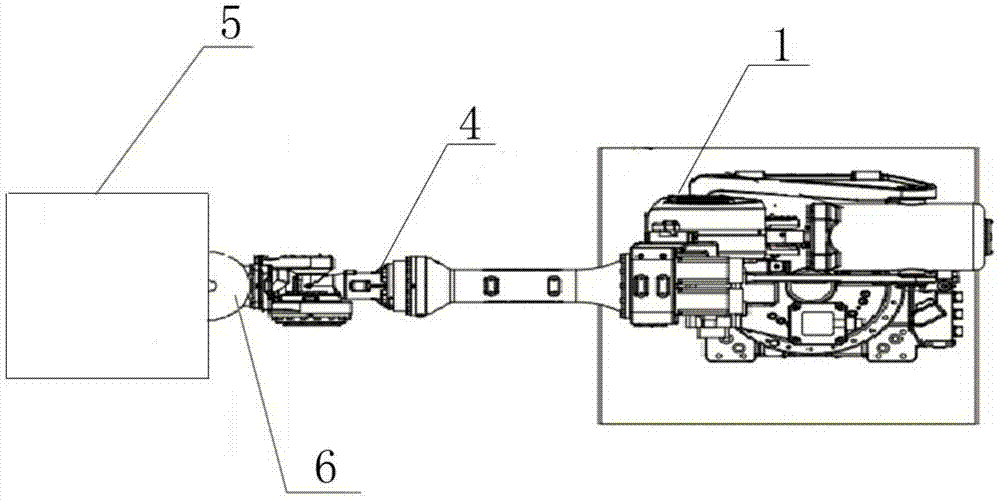

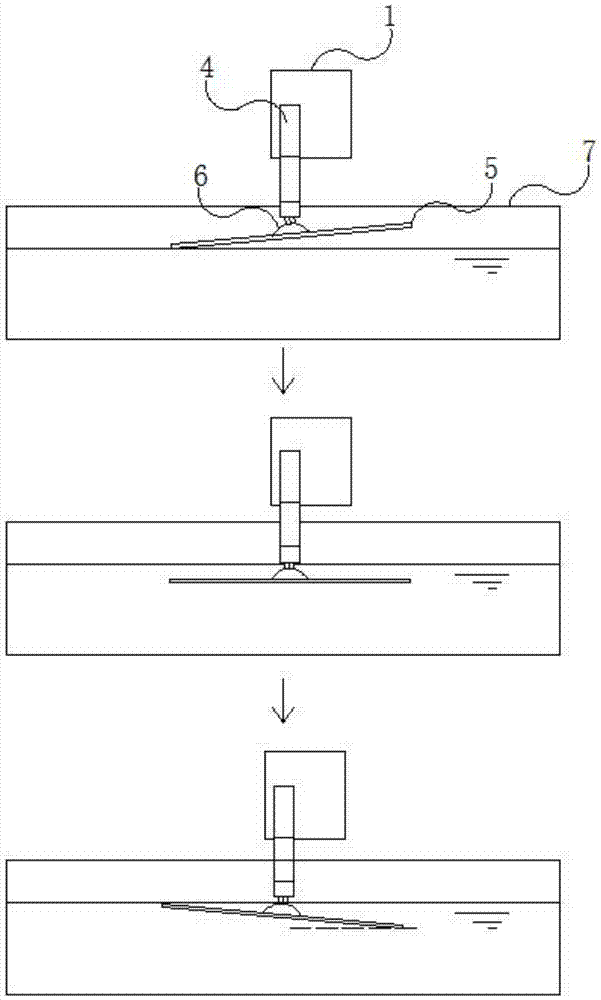

[0046] The robot 1 is provided with an operating arm 4, the front end of the operating arm 4 is provided with several suction cups 6 for absorbing the substrate substrate 5, and the robot 1 drives the operating arm 4 to move; the side of the circulating slide rail 3 is provided with a coating solution tank 7 and cleaning tank 8.

[0047] The continuous horizontal immersion coating system also includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com