Cleaning device and method for cleaning industrially manufactured components

A cleaning equipment, industrial manufacturing technology, applied in the direction of cleaning method using liquid, cleaning method using gas flow, cleaning method and utensils, etc., can solve the problems of less laundry replacement, washing clothes without consideration, unimportant, etc. To achieve the effect of improved heat absorption capacity, small loss, and increased temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

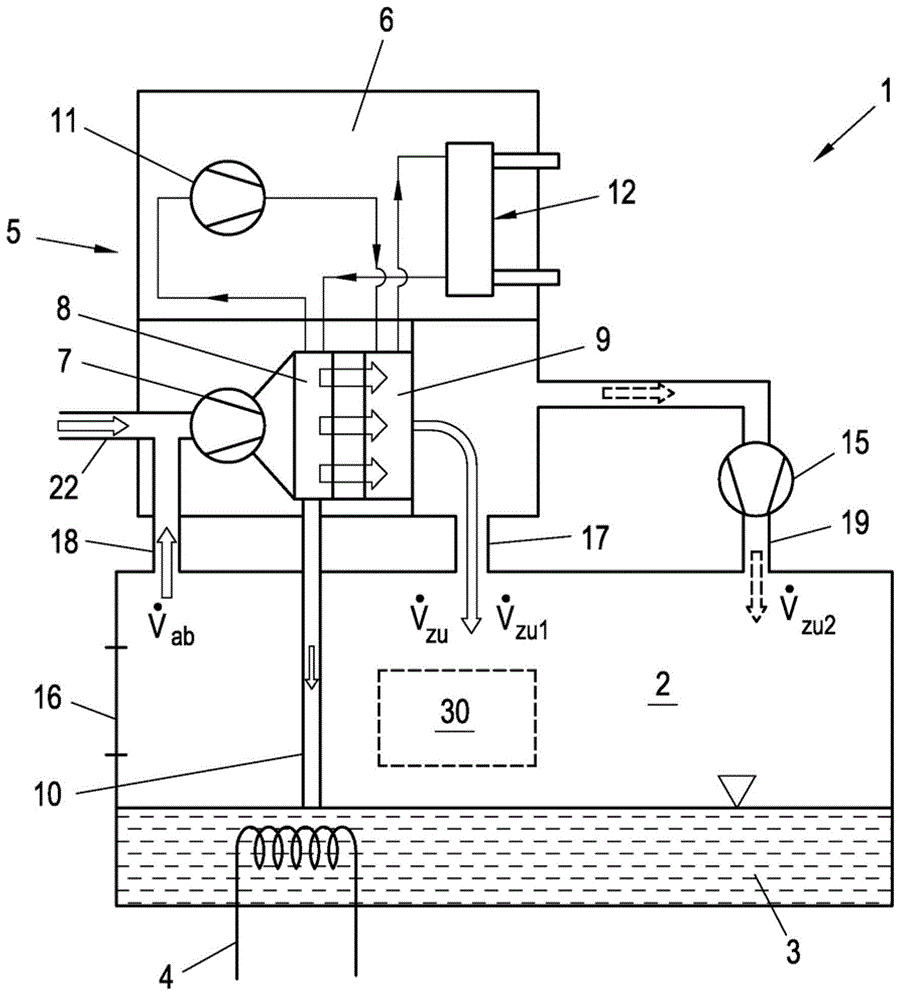

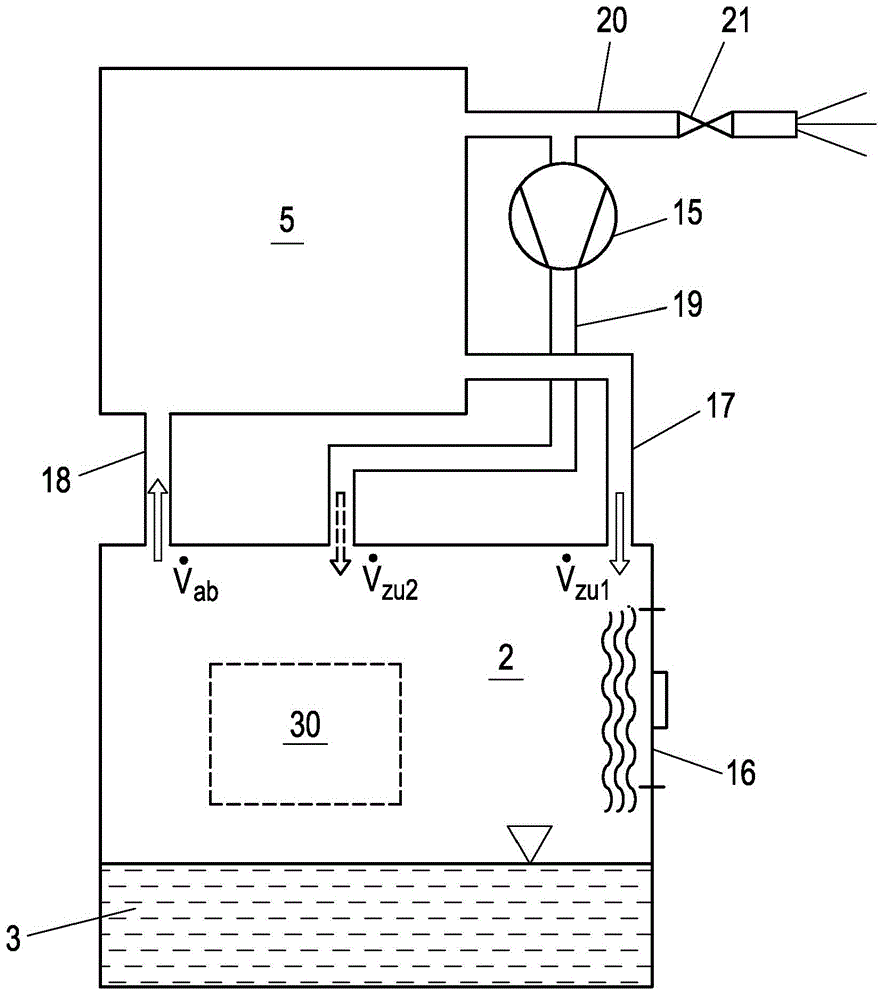

[0020] According to the cleaning device 1 of the present invention, such as figure 1 and figure 2 Schematically described, including a clean room 2, a cleaning agent container 3 and a recovery device 5, in which a component 30 is arranged during operation, such as figure 1 shown. The cleaning agent in the cleaning agent container 3 is kept at a defined operating temperature, for example 65° C. Also can be provided with detergent heating device 4 in detergent container 3 li for this, as figure 1 indicated, e.g. in order to bring the cleaning agent to or maintain the operating temperature. As cleaning agents, for example, water and chemical cleaning agents can be used. The manner in which the component 30 is cleaned in the clean room 2 is not decisive for the invention. For example, spray nozzles can be provided in the cleaning chamber 2, or robot-controlled nozzles or robot-controlled components 30 can be used. As a result of the cleaning process, a cleaning agent mist, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com