Car door conveying device

A conveying device and door technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of large area and high cost, reduce the area occupied by the equipment, reduce the manufacturing cost and save the area of the equipment area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

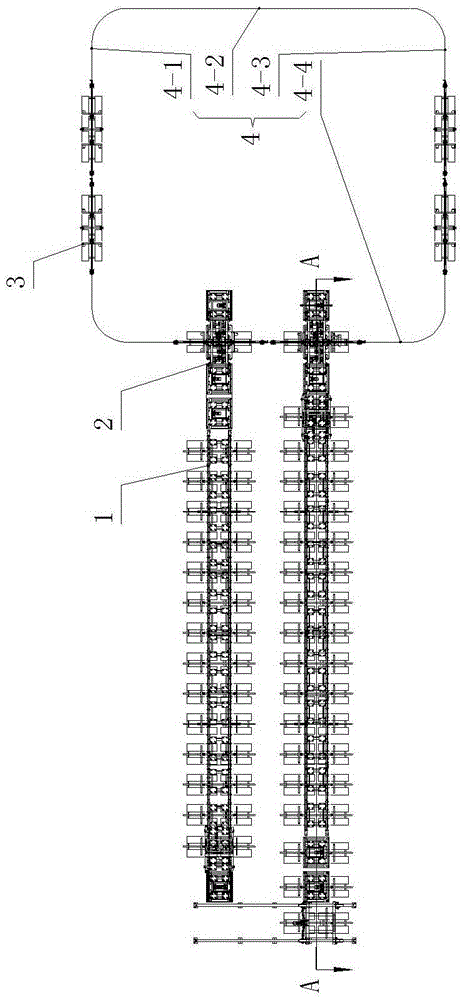

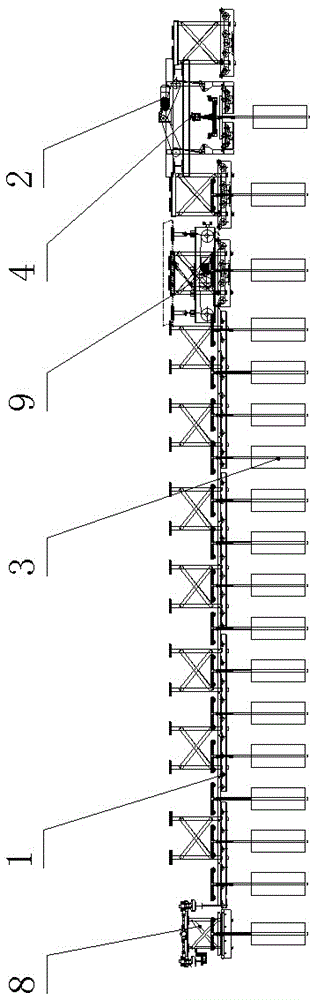

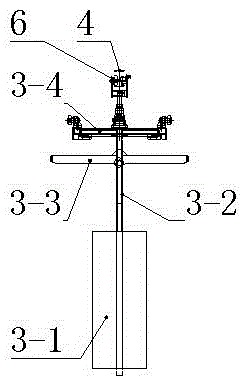

[0019] Such as figure 1 and figure 2 The shown car door conveying device includes two main raceways 1 and a spreader 3 that slides on the two main raceways 1 through a cart machine 9 and a transplanter 8 respectively, and the spreader 3 includes a lower hanger 3-1 and a Two hangers arranged opposite to each other on the lower hanger 3-1, the hanger includes two vertical bars 3-2 mounted on the lower hanger 3-1 and connected with the two vertical bars 3-2 respectively The crossbeam 3-3 is connected with the hanging bar 3-4 on the crossbeam 3-3; 3 and the bow frame formed by the hanging rods 3-4 are oppositely arranged; in this embodiment, a circular slide rail unit is provided on the two main raceways 1, and the circular track unit includes a sliding rail that slides on the circular rail 4 through the traveling wheels 7. The frame 5 and the circular rail 4 are sequentially connected by the longitudinal rail 4-4, the transverse rail 4-3, the longitudinal rail 4-2 and the tran...

Embodiment 2

[0022] Such as Figure 6 The vehicle door conveying device shown includes two main raceways 10 on which a circular slide rail unit 11 and a circular slide rail unit 12 are sequentially arranged, and other features are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com