Hydrogen flame ionization detector system with ultralow energy consumption and material consumption

A detector system, hydrogen flame technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of high occupation of public resources, impact of working environment, increase of system energy consumption, etc., to reduce system energy consumption and realize cycle The effect of running and reducing the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

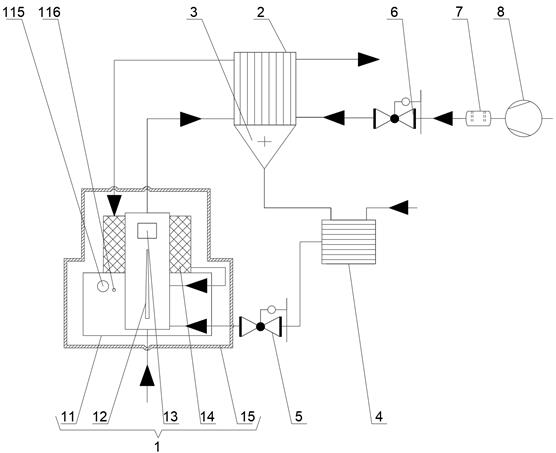

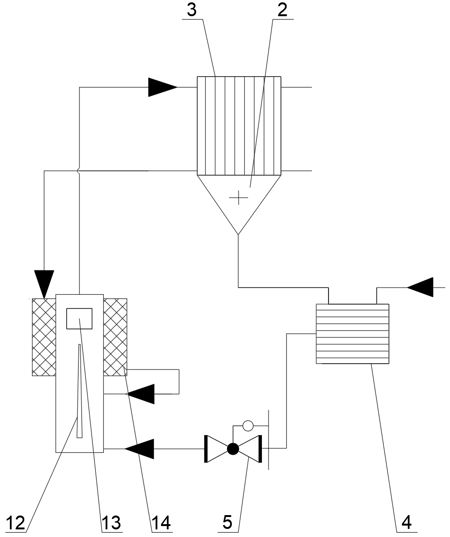

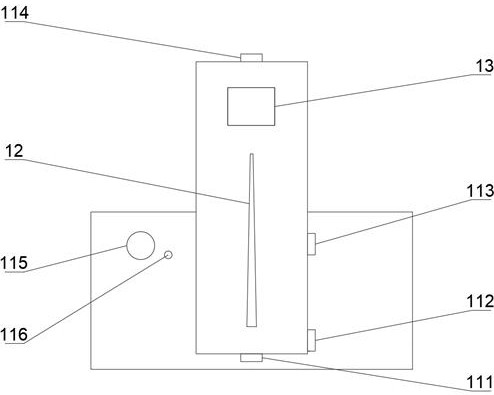

[0043] Embodiment: The concrete detection method of hydrogen flame ionization detector detection system is:

[0044] Step 1: The auxiliary gas is continuously injected into the auxiliary gas pump 8 through the pipeline for pressurization, and the pressurized auxiliary gas enters the filter 7 through the pipeline for water removal, filtration and purification, and the auxiliary gas precision flow controller 6 controls the purified auxiliary gas. The flow rate of 350mL / min enters the heat exchanger 2 for preheating. When the auxiliary gas is preheated to 220°C, it enters the catalytic oxidation reactor 14 through the auxiliary gas inlet 2 142 for purification again. The purified preheated auxiliary gas passes through the auxiliary gas outlet 143. , the pipeline and the auxiliary gas inlet 113 enter the detector body 1, and the auxiliary gas is preheated to 220 ℃ through the heat exchanger 2 to ensure that the auxiliary gas reaches the reaction temperature of the catalytic oxidant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com