Tire blank conveying system and conveying method thereof

A conveying system and embryonic technology, which is applied to the embryo conveying system and its conveying field, can solve the problems of inconsistent work efficiency and set work efficiency, unbalanced pallet supply in pallet transfer operations, and accumulation of embryos in molding stations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

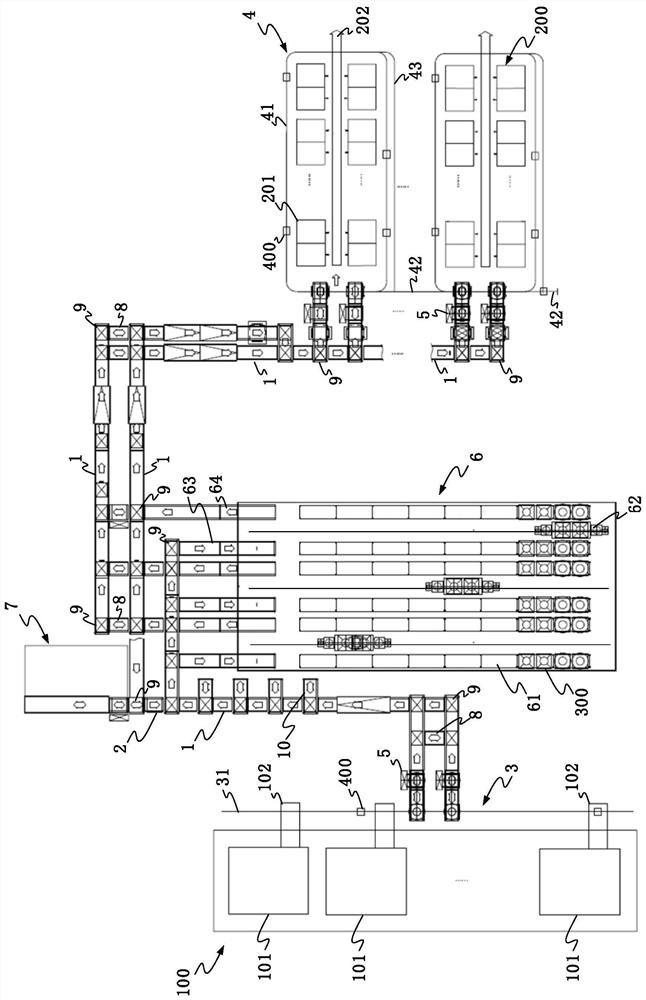

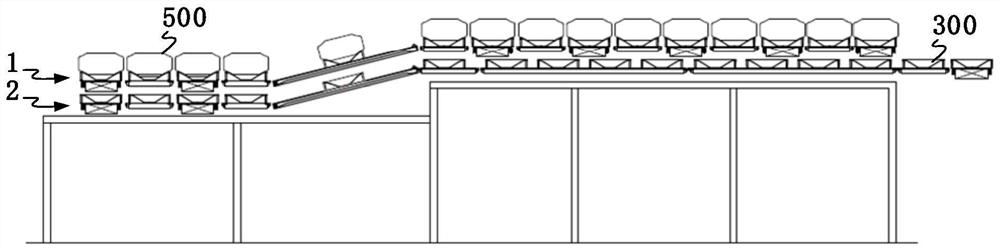

[0061] see figure 1 , the present embodiment provides a embryo conveying system, the embryo conveying system can be applied in the embryo production factory, it can transport the tray 300 from the molding station 100 for forming the embryo 500 to the vulcanizing embryo 500 The vulcanization station 200 of the vulcanization station 200, and the green tire 500 is placed on the tray 300, and the green tire 500 output from the molding station 100 is transported to the vulcanization station 200.

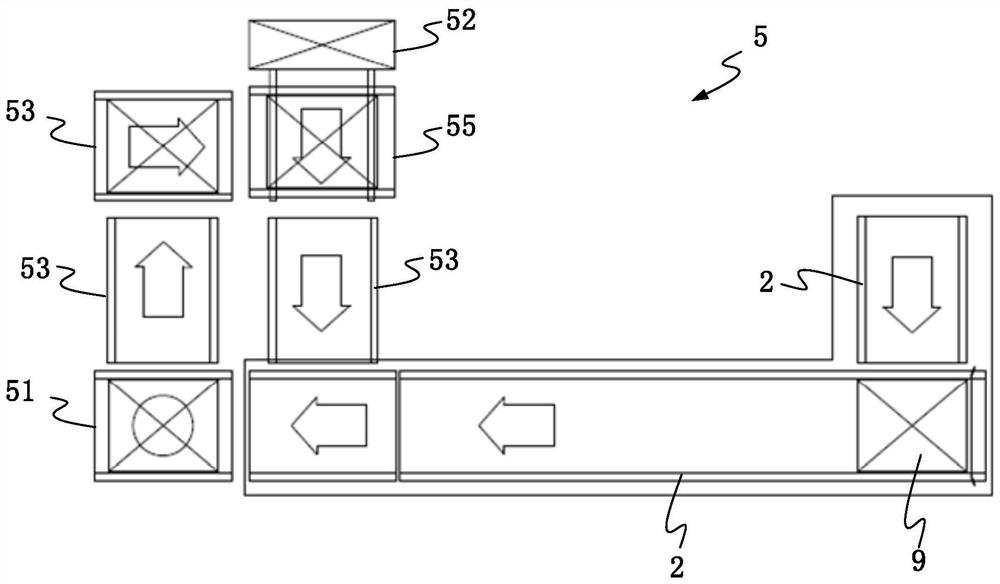

[0062] In order to enable the tray 300 to flow back to the molding station 100 for standby after being transported to the vulcanization station 200, and to receive the embryo 500 again, the embryo conveying system provided in this embodiment specifically includes a conveying line 1, a return line 2, a second A conveying device 3 and a second conveying device 4 and a transfer device 5 . Wherein, the first conveying device 3 is arranged at the output end of the molding station 100, and it ...

Embodiment 2

[0107] see Figure 8 The embryo conveying system provided in this embodiment is generally the same as that in Embodiment 1, the difference is that in this embodiment, a different structure is used to adjust the number of trays 300 circulating in the embryo conveying system. In the present embodiment, only one turnover warehouse (i.e. the first turnover warehouse 6) is arranged, and the second turnover warehouse 7 is not provided. The pallet 300 of the embryo 500 is used to adjust the number of pallets 300 on the conveying line 1; the turnover warehouse is also configured to store and output the empty pallets 300 transported by the return line 2, so as to adjust the number of pallets 300 on the return line 2 quantity.

[0108] Specifically, the input end and the output end of the turnover warehouse are respectively provided with a warehouse-in line 63 for receiving the pallet 300 and a warehouse-out line 64 for outputting the pallet 300, wherein a pair of warehouse-in lines 63...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com