Leftover material recycling and granulating machine

A technology of scrap recycling and granulator, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of scrap recycling pollution and inability to recycle online, achieve good recycling effect, avoid scrap pollution, and improve equipment adaptation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

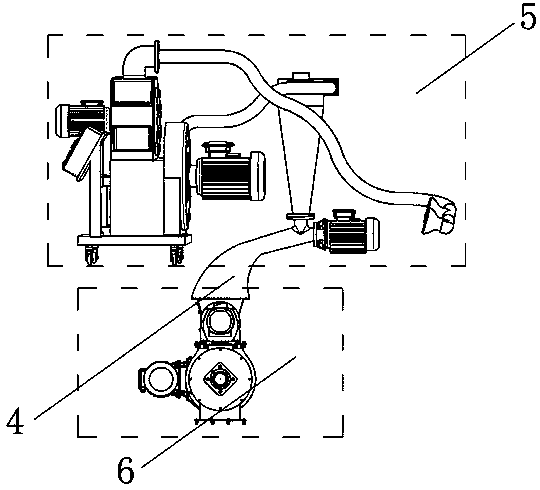

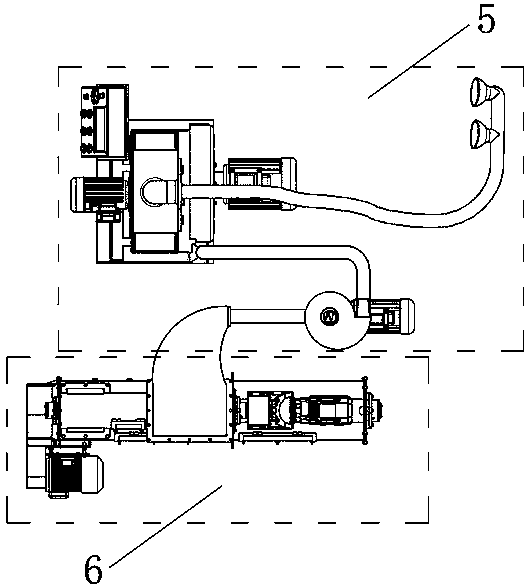

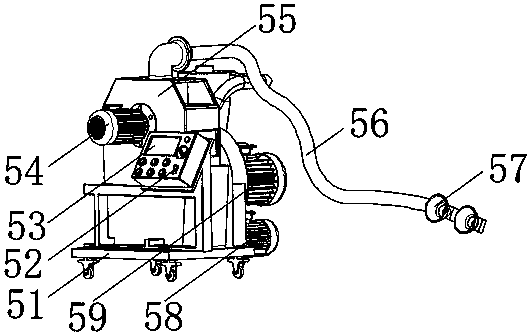

[0027] Such as Figure 1-5 As shown, the embodiment of the present invention provides a side material recovery granulator, including a side material recovery component 5 and a granulation component 6, characterized in that a communication pipeline 4 is provided between the side material recovery component 5 and the granulation component 6 , the scrap recycling assembly 5 includes a main machine base 51, the top of the main chassis 51 is provided with a crushing main chamber 55, the end of the crushing main chamber 55 is provided with a scrap recovery pipe 56, and the end of the scrap recycling pipe 56 is provided with a scrap suction pipe. Nozzle 57, granulation assembly 6 includes a screw main chamber 61, the end of the screw main chamber 61 is bolted to one side of the scrap recovery assembly 5 through a communication pipe 4, and one side of the screw main chamber 61 is provided with an extrusion chamber 63 , the top of the screw main cavity 61 is provided with an anti-drop ...

Embodiment 2

[0029] Such as Figure 1-3 As shown, the embodiment of the present invention provides a side material recovery granulator, a crushing motor 54 is provided on one side of the crushing main cavity 55, a main control panel 53 is provided at the middle of one side of the main machine base 51, and the surface of the main control panel 53 is An emergency switch 52 is embedded, a main suction fan 59 is provided in the middle part of the back of the main machine base 51, and an auxiliary fan 58 is provided at the bottom of the back of the main machine base 51. shape, and the spatial shape of the edge material suction nozzle 57 is a double-layer film nozzle, the edge material suction nozzle 57 is preferably formed by a thin film memory metal sheet metal as a whole, and the inner wall of the edge material recovery pipe 56 is coated with a nanometer layer, and the edge material The process control point on the inner wall of the recovery pipe 56 is smooth and has no protrusions. The conne...

Embodiment 3

[0031] Such as figure 1 , 4 As shown, the embodiment of the present invention provides a side material recovery granulator, the side surface of the screw main chamber 61 and the extrusion chamber 63 is hinged with a monitoring side door 62, and the bottoms of the two ends of the screw main chamber 61 and the extrusion chamber 63 are fixed Mounting feet 64 are welded, the end of the extrusion cavity 63 is provided with an extrusion nozzle 65, and the driving screw 68 is provided with a feeding screw motor 66 on the side of the anti-falling hopper 612, between the feeding screw motor 66 and the driving screw 68. Coupling reducer 67 is provided, and one end of driving screw 68 far away from feeding screw motor 66 is provided with lubricating oil cavity 69, and the other end of screw main cavity 61 is parallel fixedly bolted with driving force motor 611, and the output end of driving force motor 611 A protective cover plate 610 is provided for the transmission between the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com