Ceramic membrane aeration and micro-positive pressure ozone membrane regeneration water treatment method and treatment device

A treatment method and technology of a treatment device, which are applied in biological water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of low system operation efficiency, low ozone utilization rate, and high operation cost, and achieve the use of Longer life, improved filtration efficiency, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

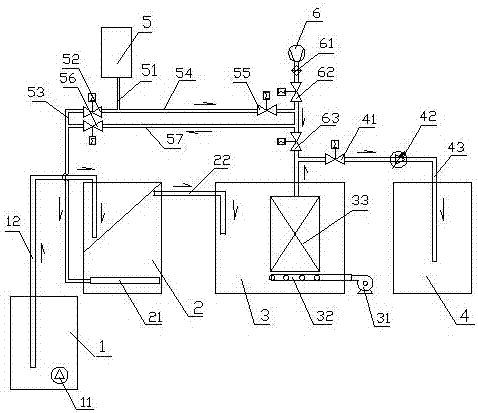

[0029] Such as figure 1 Among them, the water treatment device of the present invention includes a regulating tank 1, a pretreatment tank 2, a membrane tank 3, a water purification tank 4, an ozone generator 5 and an air compressor 6, and a submersible pump 11 is arranged in the regulating tank, and the regulating tank It is connected with the outlet pipe 12 of the regulating tank for the pretreatment tank. The pretreatment tank is provided with a nano-ceramic membrane aeration diaphragm 21. A membrane module 34 is arranged in the membrane tank, and an aeration pipe 32 is arranged at the lower part of the membrane module. The tube is connected to the Roots fan 31 (or its centrifugal fan), the pretreatment tank is connected to the membrane tank with the pretreatment tank outlet pipe 22, the ozone generator is connected to the ozone outlet pipe 51, and the ozone outlet pipe passes through the ozone aeration solenoid valve 52 and the ozone film washing electromagnetic valve 55 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com