Cleaning method of immersion membrane filtration system

A technology of submerged membrane and filtration system, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of short service life of membrane components, prolong service life, avoid operation errors, and improve cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

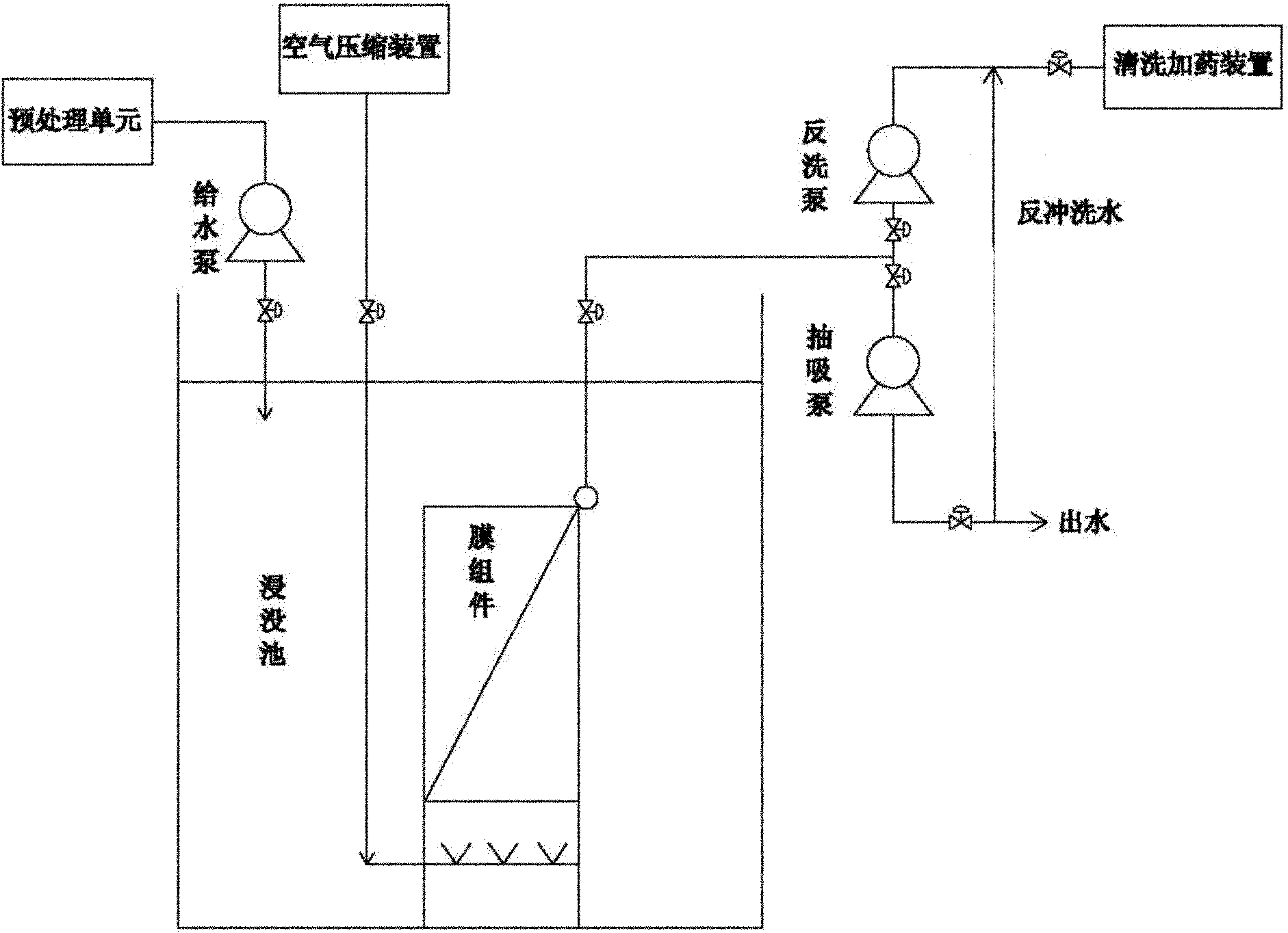

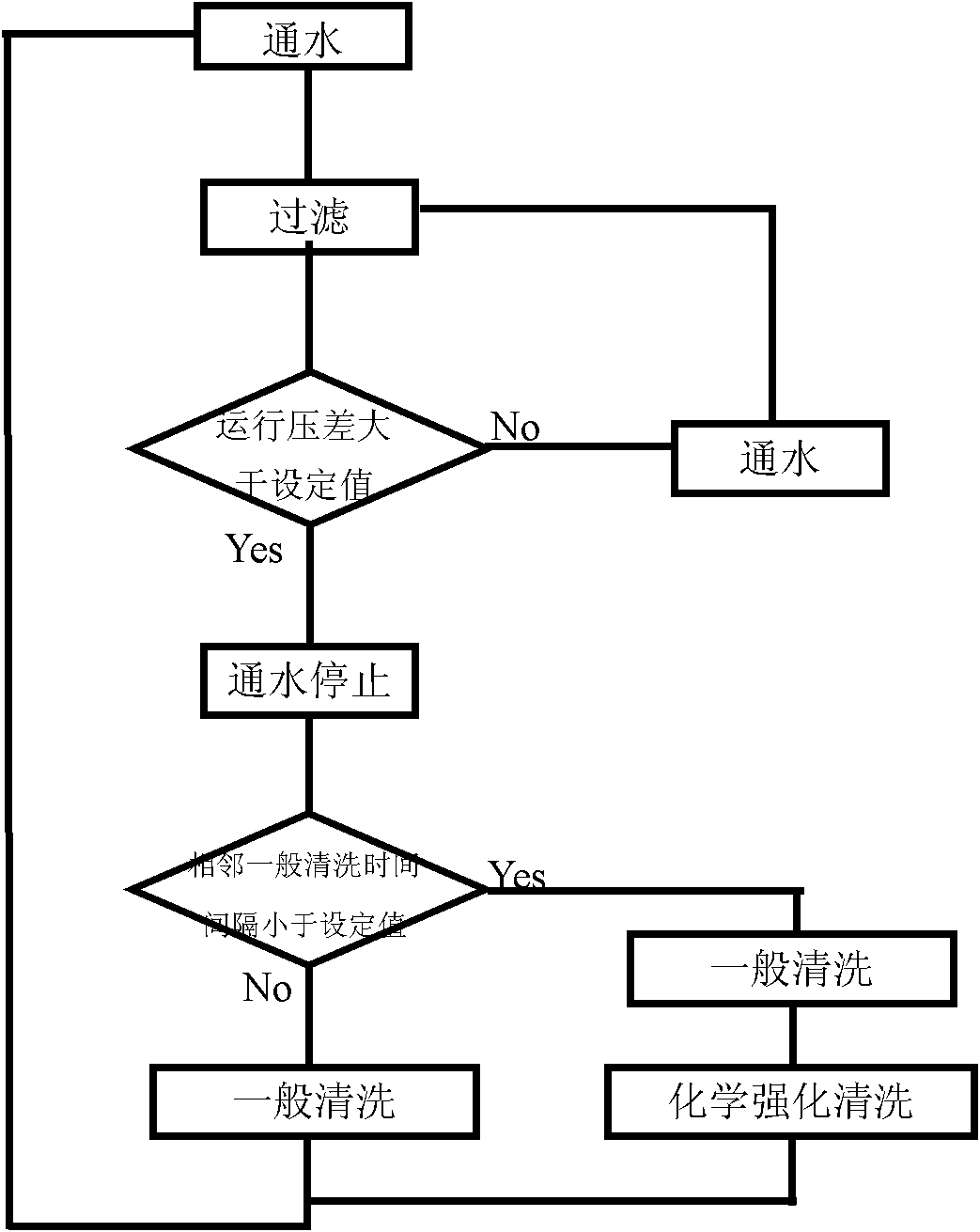

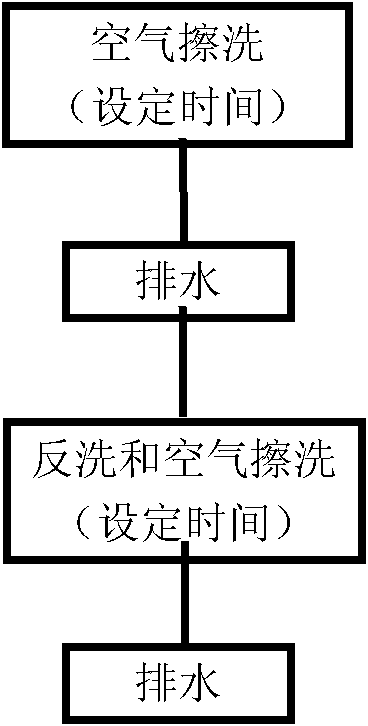

Method used

Image

Examples

Embodiment 1

[0033] This test uses a certain surface raw water, its turbidity is about 10NTU, COD Mn At about 3mg / L, iron at about 0.3mg / L. The raw water quality belongs to Class III water body, and the water body is only slightly polluted. The operating process of the system is the process of online coagulation + submerged ultrafiltration. The submerged ultrafiltration membrane is a hollow fiber ultrafiltration membrane with a pore size of 0.01 micron and the material is PVDF ultrafiltration membrane. The operating flux is 1.5m / d. The set pressure difference of the whole system is 50KPa, that is, when the pressure difference of the ultrafiltration membrane is greater than 50KPa for 35s, the system will automatically perform general cleaning on the submerged ultrafiltration system, and then the system will continue to operate. If the time interval between two adjacent general cleanings is reduced to 25 minutes, the system will automatically perform chemical enhanced cleaning on the subm...

Embodiment 2

[0039] This test uses a certain surface raw water, its turbidity is about 40NTU, COD Mn Around 5mg / L, iron around 2mg / L. The quality of the raw water belongs to Class V water body, and the pollution is relatively serious. The operating process of the system is the process of online coagulation + submerged ultrafiltration. The submerged ultrafiltration membrane is a hollow fiber ultrafiltration membrane with a pore size of 0.01 micron and the material is PVDF ultrafiltration membrane. The operating flux is 1.3m / d. The set pressure difference of the whole system is 45KPa, that is, when the pressure difference of the ultrafiltration membrane is greater than 45KPa for 45s, the system will automatically perform general cleaning on the submerged ultrafiltration system, and then the system will continue to operate. If the time interval between two adjacent general cleanings is less than 20 minutes, the system will automatically perform chemical enhanced cleaning on the submerged u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com