Solid waste plasma gasification treatment device and method

A plasma and solid waste technology, applied in separation methods, chemical instruments and methods, gasification technology, etc., can solve the problems of a large amount of fly ash produced by incineration technology, limited applicability, high technical requirements, etc., and solve the problem of secondary pollution , the effect of strengthening the degree of harmlessness and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

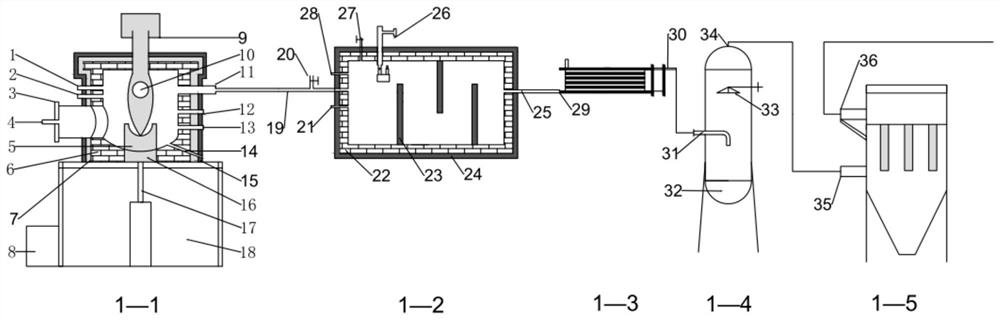

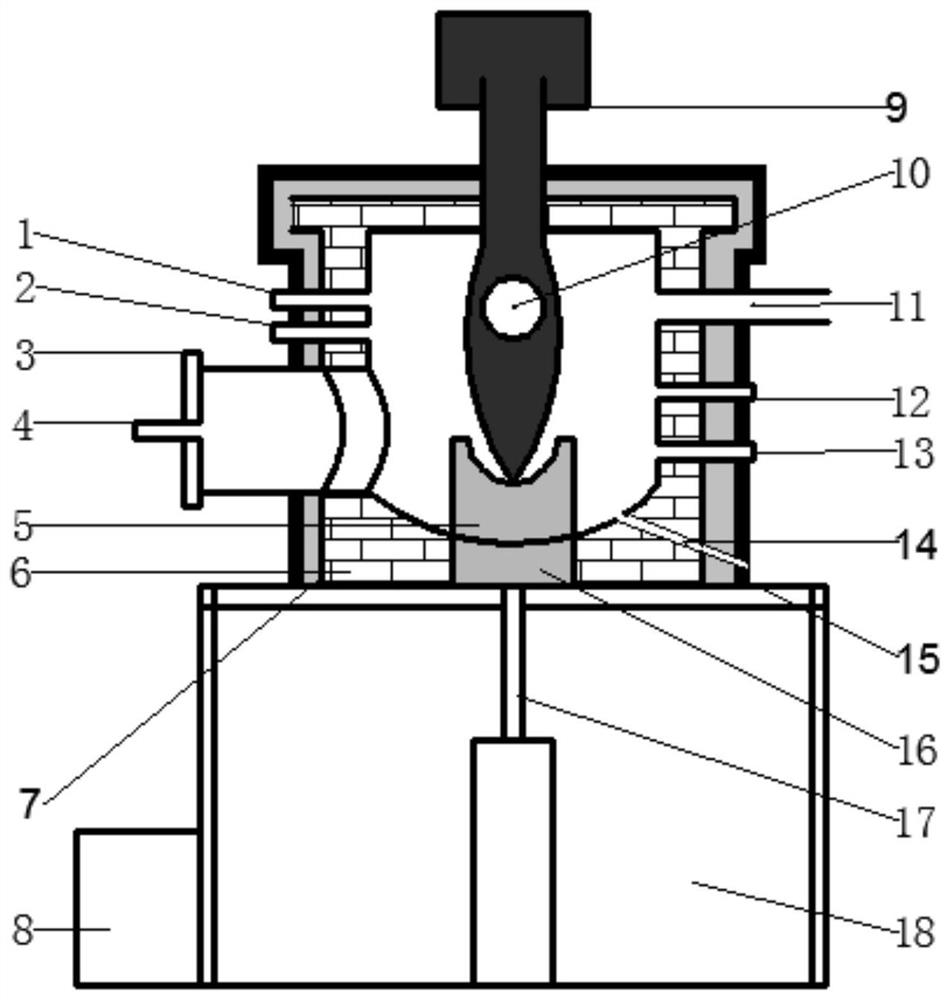

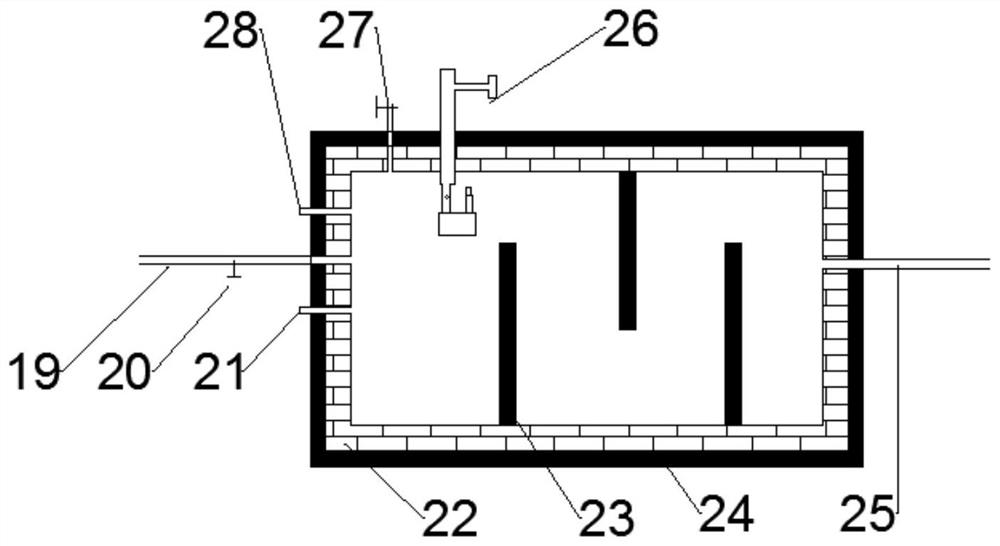

[0036] Such as figure 1 As shown, the system mainly includes a plasma gasifier (1-1), a secondary combustion chamber (1-2), a condenser (1-3), a spray tower (1-4) and a bag filter (1 —5). The specific content is as follows:

[0037]The gasification furnace adopts the plasma gasification furnace, which utilizes the characteristics of fast heating speed and high temperature of plasma technology to quickly gasify solid waste, and has strong adaptability to raw materials, and can be used to treat hazardous waste such as medical waste. In the gasifier, a plasma torch (9) with a power of 10-1000KW is vertically inserted into the top of the furnace, which can be lifted; the pressure range of the working gas (such as air, etc.) at the entrance of the plasma torch is 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com