Treatment agent and method for removing hexavalent chromium in sludge

A treatment agent, hexavalent chromium technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, sludge detoxification, etc., can solve the problems of difficult application, complex composition, and increased difficulty of sludge reprocessing, etc. Achieve the effect of reducing moisture content and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

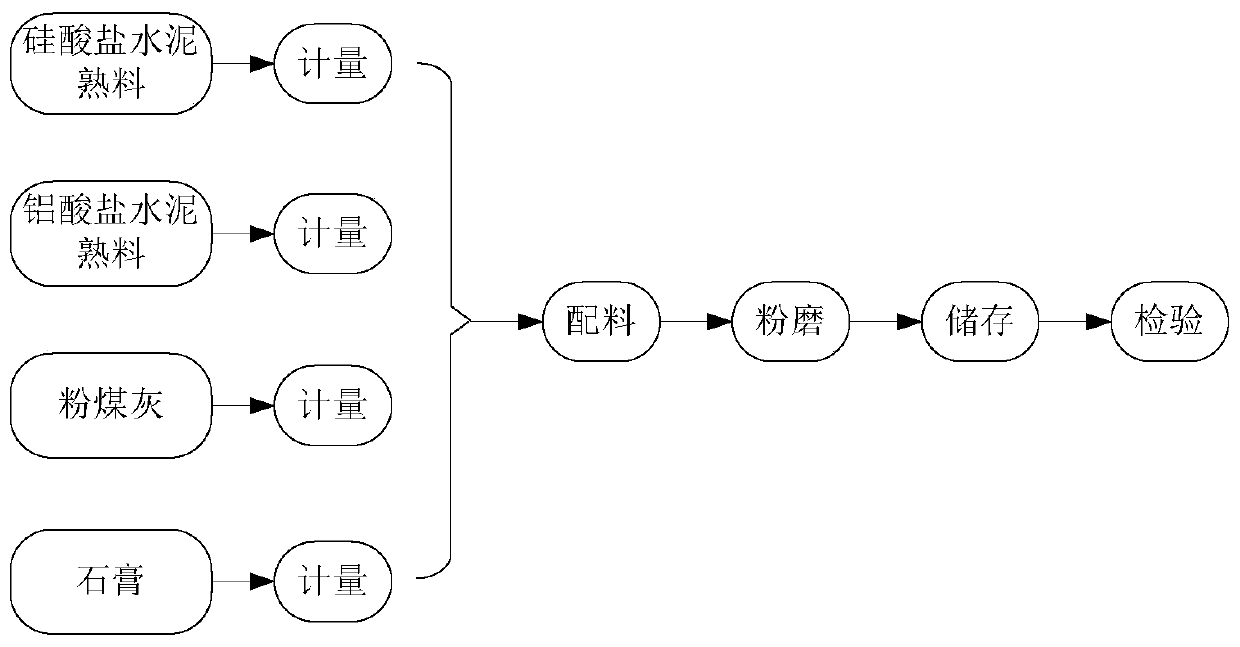

[0033] In view of the above deficiencies, the present embodiment provides a treatment agent for removing hexavalent chromium in sludge, which comprises the following components: Portland cement clinker, aluminate cement clinker, fly ash, gypsum and Carbonate, the mass ratio of each component is Portland cement clinker: aluminate cement clinker: fly ash: gypsum: carbonate is 100:20~120:5~40:4~8:0.1~ 5.

[0034] Among the above treatment agents, the strength of Portland cement clinker is greater than 52.5MPa, the fly ash meets the requirements of GB / T1596, the content of alumina in aluminate cement clinker is ≥50%, and SO in gypsum 3 Content ≥ 32%. The carbonate is an industrial-grade water-soluble carbonate, such as any one of ammonium carbonate, sodium carbonate, and potassium carbonate, or other commonly used industrial-grade carbonate that can realize water-soluble generation of carbonate.

[0035] In a preferred embodiment of the present embodiment, the above-mentioned tr...

Embodiment 2

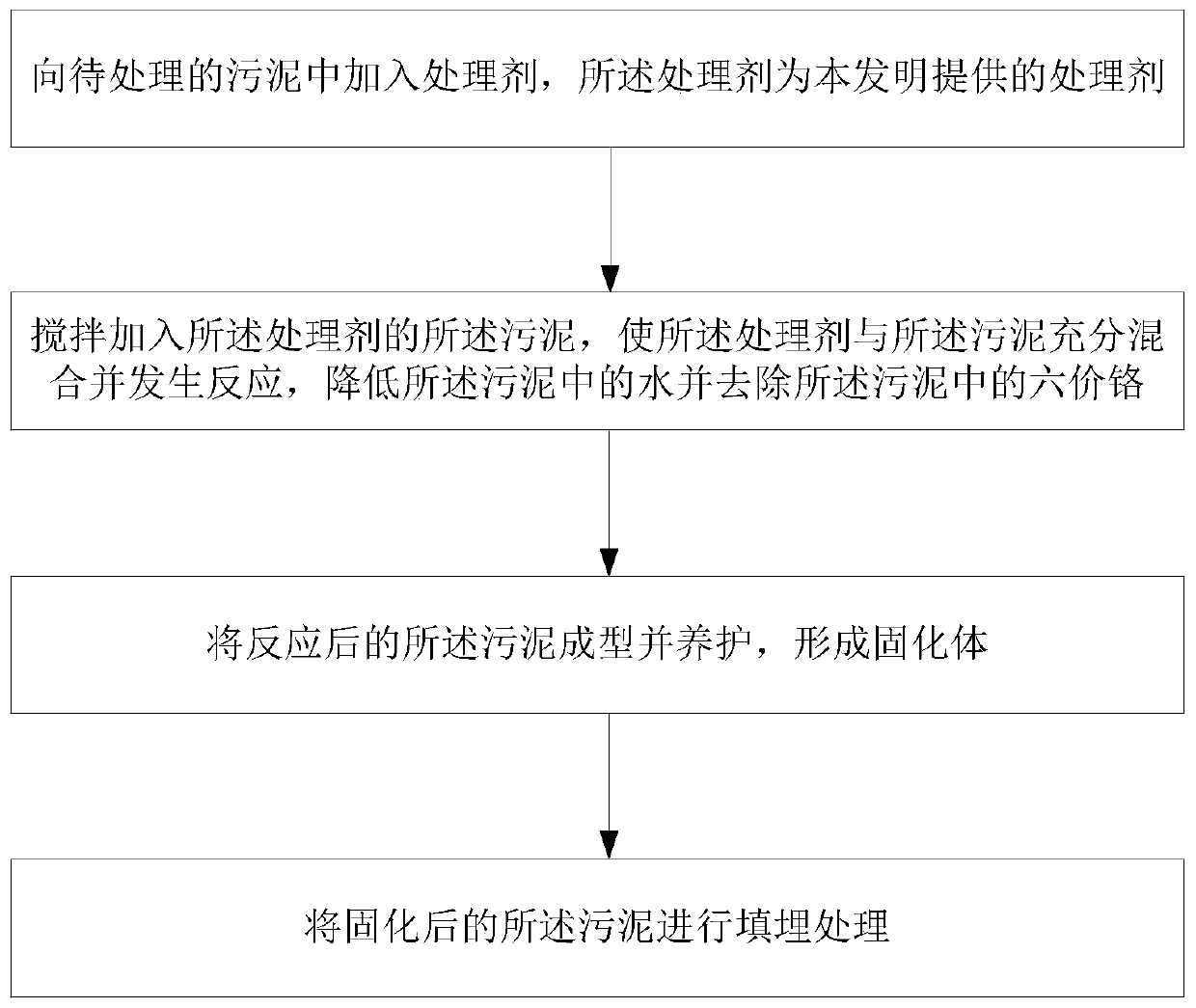

[0040] This embodiment provides a method for removing hexavalent chromium in sludge, such as figure 2 As shown, the method includes the following steps:

[0041] Adding a treatment agent to the sludge to be treated, the treatment agent is the treatment agent provided by the present invention;

[0042] Stirring the sludge to which the treating agent is added, allowing the treating agent to fully mix and react with the sludge, reducing water in the sludge and removing hexavalent chromium in the sludge;

[0043] forming and curing the reacted sludge to form a solidified body;

[0044] The solidified sludge is landfilled.

[0045] In this embodiment, the sludge that needs to be treated is the sludge of a water treatment plant, and the sludge is usually high-water sludge with a water content less than or equal to 96%, and the hexavalent chromium content in the high-water sludge is about 1 mg / 1000g. The above-mentioned treatment agent accounts for 5 to 40% of the wet weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com