Solid waste size reduction treatment device

A processing device and technology for solid waste, applied in the direction of grain processing, etc., can solve the problems of high cost of solid waste treatment, impact on the marine ecological environment, and high labor intensity of workers, and achieve long-term overseas navigation convenience, widening the size range, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

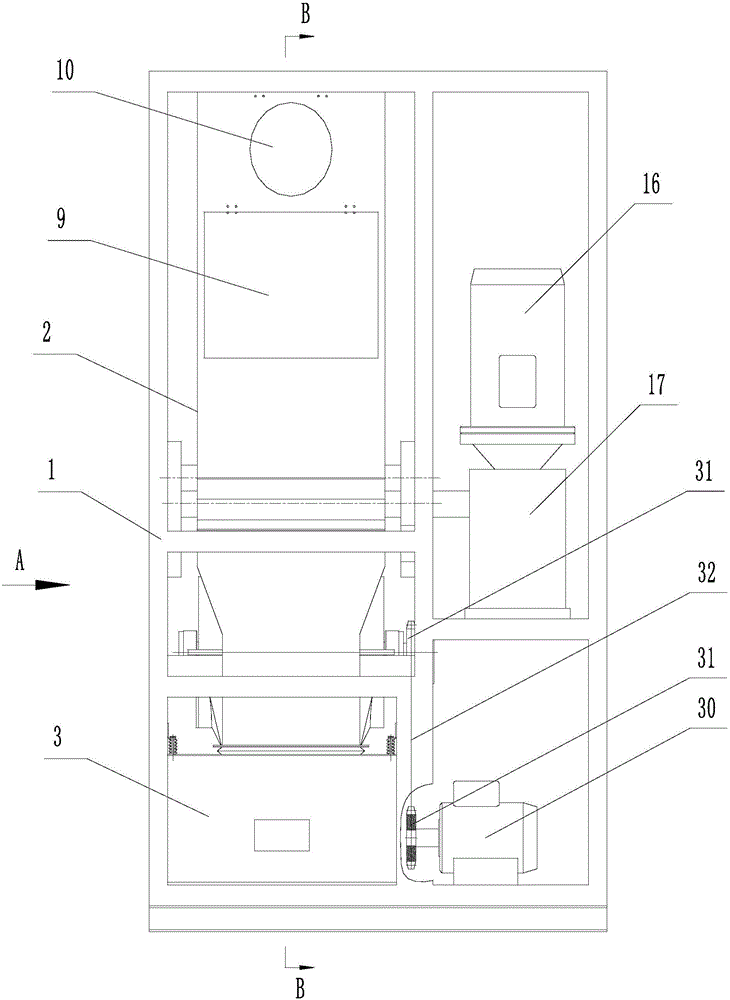

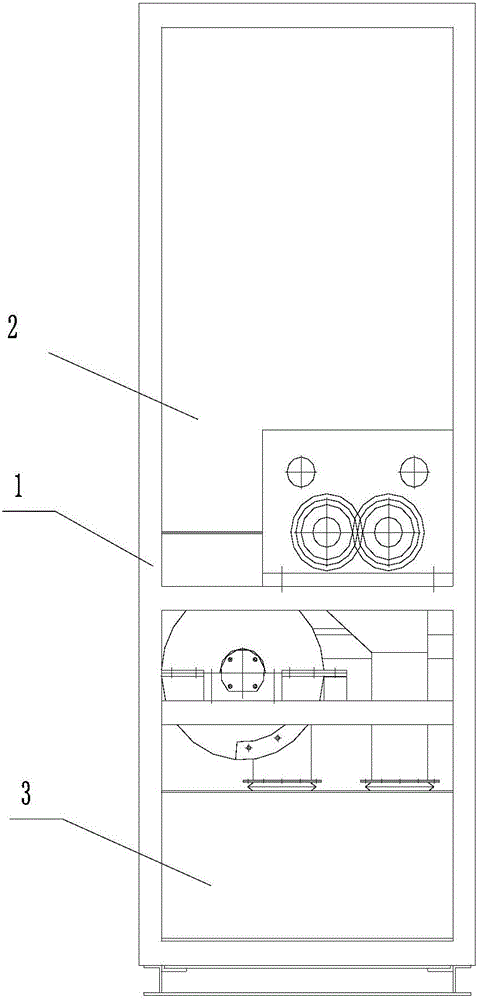

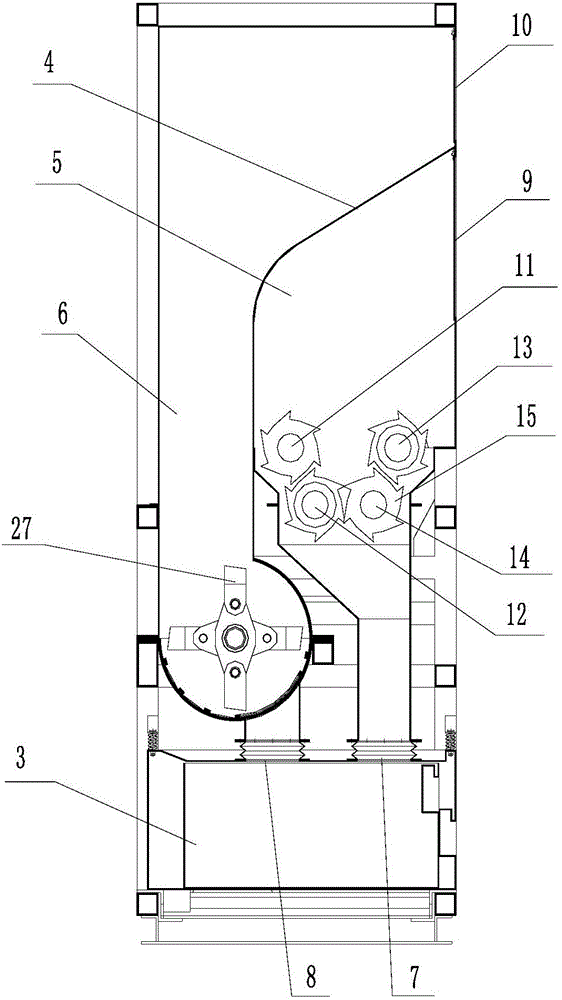

[0036] In this embodiment, a solid waste volume reduction treatment device, such as Figure 1 to Figure 3As shown, it includes frame 1, hopper 2, slag receiving box 3, hob crushing mechanism, hob driving mechanism, hammer breaking mechanism and hammer driving mechanism. The hopper is installed on the upper part of the frame, and the slag receiving box is installed on the frame. In the lower part, there is a partition 4 inside the hopper, and the partition divides the inner cavity of the hopper into a hob crushing chamber 5 and a hammer crushing chamber 6. The hob crushing mechanism is installed in the hob crushing chamber, and the hammer crushing chamber is installed Mechanism, the hob crushing mechanism is connected with the hob driving mechanism, the hammer breaking mechanism is connected with the hammer driving mechanism, and both the hob driving mechanism and the hammer driving mechanism are installed on the frame. The hopper is divided into two independent processing cham...

Embodiment 2

[0050] This embodiment is a solid waste volume reduction treatment device. Compared with Embodiment 1, the difference lies in that: in the hammer crushing cavity, a screen is provided below the hammer crushing mechanism. The screen is set near the outer edge of the hammer. When the material is crushed by the hammer, if the size of the material is smaller than the aperture of the screen, the material will be sent out directly from the second outlet. If the size of the material is larger than the screen If the hole diameter is large, the material stays under the hammer crushing mechanism, and is further crushed by the constantly rotating hammer until the material can be discharged through the screen.

Embodiment 3

[0052] This embodiment is a solid waste volume reduction treatment device. Compared with Embodiment 1, the difference is that: there is also a guide rail assembly at the connection between the bottom of the slag receiving box and the frame, and the guide rail assembly generally adopts a circular guide rail commonly used in the market. The components are convenient for users to take out or put into the slag receiving box.

[0053] Example 2

[0054] This embodiment is a four-shaft shredder for solid waste. Compared with Embodiment 1, the difference is that: the frame is also provided with a recovery box, and the recovery box is located below the discharge port. Recycling bins are added to facilitate the collection of recyclable materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com