High-temperature melting and solidifying method for heavy metal sludge

A technology of heavy metal sludge, high temperature melting, applied in chemical instruments and methods, sludge treatment, fixed/solidified sludge treatment, etc. The effect of high utilization efficiency, high stability and low leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

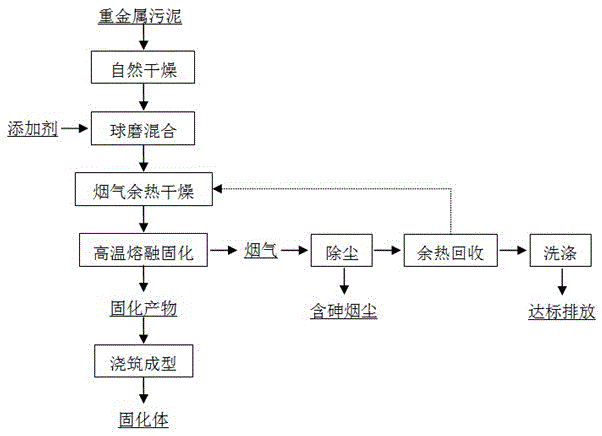

[0019] Such as figure 1 As shown, the heavy metal sludge high-temperature melting solidification method, its specific steps are as follows:

[0020] (1) First, add 1% of the weight of the natural air-dried heavy metal sludge to the natural air-dried heavy metal sludge (see Table 1 for the composition of the heavy metal sludge) and mix it with ball mill until the particle size is 2 ;

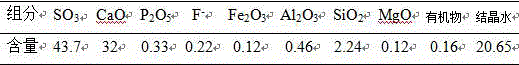

[0021] Table 1 Chemical composition of arsenic-containing heavy metal sludge (%)

[0022]

[0023] (2) Dry the ball-milled material obtained in step (1) for 3 hours at a temperature of 100° C. using the waste heat of flue gas;

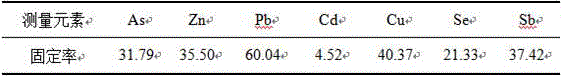

[0024] (3) Heat the material dried in step (2) to a temperature of 1000°C and melt it at a high temperature for 3 hours. The flue gas generated during this process is dedusted and returned to step (2) for drying and ball milling. The temperature of the material is reduced to 50°C Post-washing (washing with a sodium hydroxide solution with a concentration of 3mol / l fo...

Embodiment 2

[0033] Such as figure 1 As shown, the heavy metal sludge high-temperature melting solidification method, its specific steps are as follows:

[0034] (1) First, add 10% of the weight of the natural air-dried heavy metal sludge to the natural air-dried heavy metal sludge (the composition of the heavy metal sludge is shown in Table 4) and mix it with ball mill until the particle size is 2 ;

[0035] Table 4 Chemical composition of arsenic-containing heavy metal sludge (%)

[0036]

[0037] (2) Dry the ball-milled material obtained in step (1) for 0.1 h at a temperature of 800° C. using the waste heat of flue gas;

[0038] (3) Heat up the material dried in step (2) to a temperature of 1400°C and melt it at high temperature for 0.1 hour. The flue gas generated during this process is dedusted and returned to step (2) for drying and ball milling. The temperature of the material drops to 80 After washing at ℃ (using a sodium hydroxide solution with a concentration of 3mol / L for 0...

Embodiment 3

[0047] Such as figure 1 As shown, the heavy metal sludge high-temperature melting solidification method, its specific steps are as follows:

[0048] (1) First, add 15% of the weight of the natural air-dried heavy metal sludge to the natural air-dried heavy metal sludge (see Table 7 for the composition of the heavy metal sludge) and mix it with ball mill until the particle size is 2 ;

[0049] Table 7 Chemical composition of arsenic-containing heavy metal sludge (%)

[0050]

[0051](2) Drying the ball-milled material obtained in step (1) for 1.5 hours at a temperature of 500° C. using waste heat of flue gas;

[0052] (3) Heat up the material dried in step (2) to a temperature of 1200°C and melt it at high temperature for 1.5 hours. The flue gas generated during this process is dedusted and returned to step (2) for drying and ball milling. The temperature of the material drops to 100°C After washing at ℃ (with a concentration of 3mol / L sodium hydroxide solution, wash for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com