Domestic sludge pyrolysis treatment process

A treatment process and technology for domestic sludge, which is applied in the directions of pyrolysis sludge treatment, dewatering/drying/concentrating sludge treatment, and by-product vaporization, etc. The effect of low emissions, high energy efficiency and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

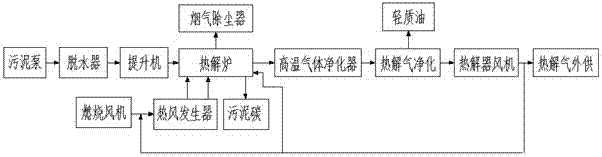

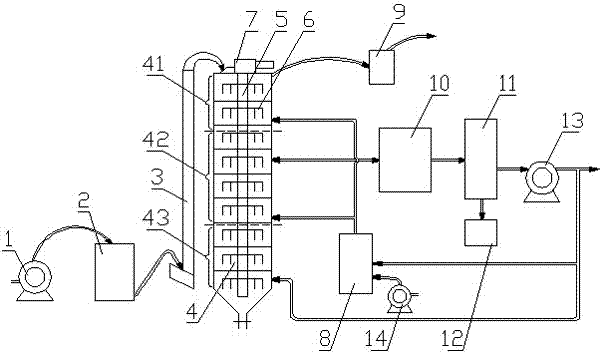

[0021] figure 1 It is a flow chart of domestic sludge pyrolysis treatment process, figure 2 It is a structural schematic diagram of domestic sludge pyrolysis treatment, and the domestic sludge pyrolysis treatment process includes the following steps:

[0022] 1) Turn on the sludge pump 1, the sludge pump 1 sends the sludge into the dehydrator 2, the dehydrator 2 dehydrates the sludge and then enters the elevator 3, and the elevator 3 lifts the dehydrated sludge and enters it into the pyrolysis furnace 4 tops.

[0023] 2) A stirring shaft 5 is arranged in the pyrolysis furnace 4 along its axial direction, and stirring blades 6 are evenly distributed on the stirring shaft 5, and the motor 7 drives the stirring shaft 5 to drive the stirring blades 6 to stir in the pyrolysis furnace 4; the pyrolysis furnace 4 The interior is divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com