A method and system for dehydrating and refining aged oil

A refining method, a technology for aging oil, applied in the direction of using waste oil refining, chemical dehydration/demulsification, refining hydrocarbon oil, etc., can solve the problems of increased burden on enterprises, high operating costs, limited application, etc., and achieve short residence time. , the effect of reducing the extraction dose and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

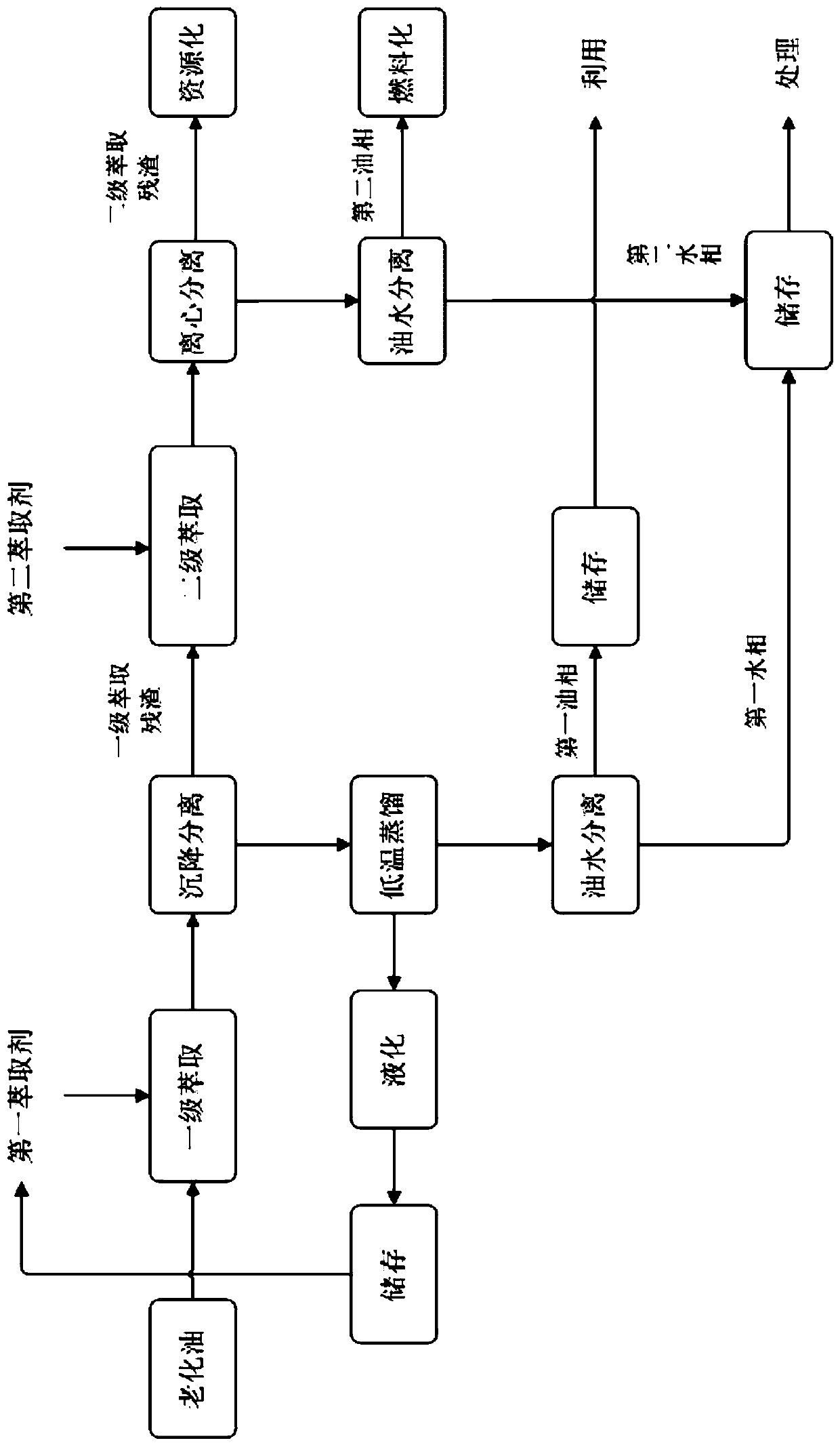

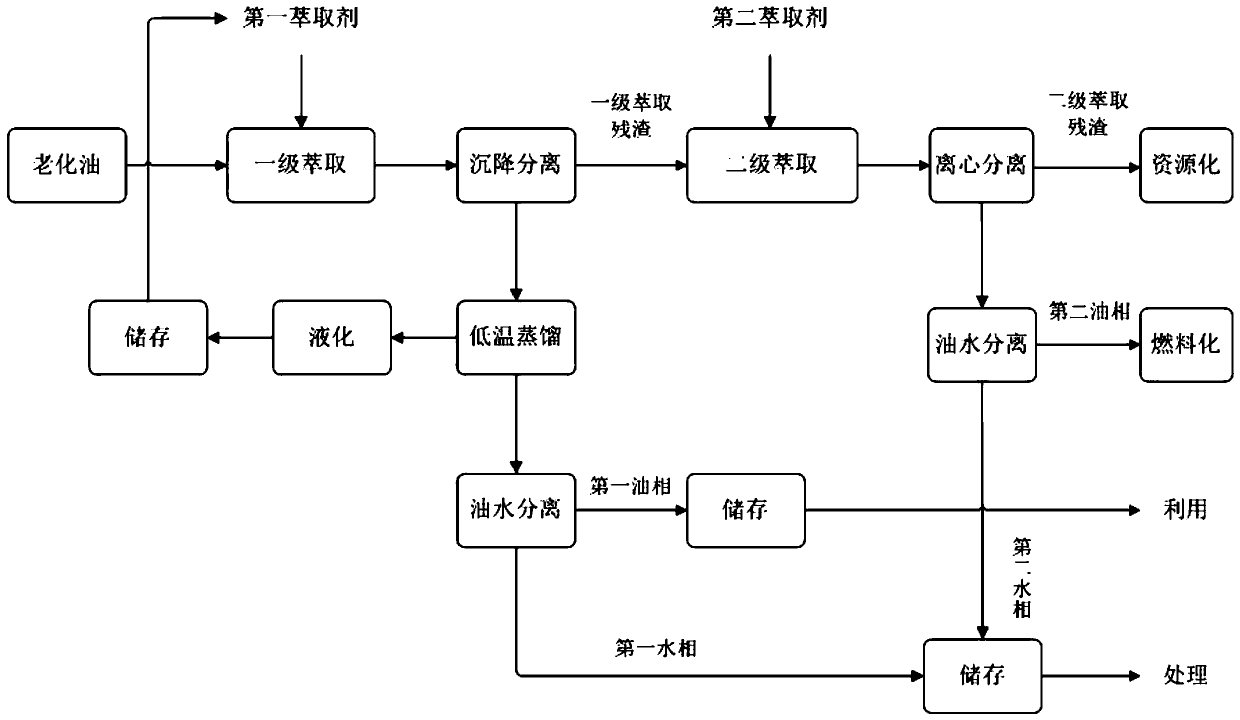

[0056] This embodiment provides a kind of aging oil dehydration refining method (flow process is as follows figure 1 shown).

[0057] The system used is summarized as follows:

[0058] The primary extraction unit, the primary extraction unit includes a primary extractor, a primary solid-liquid separator (sedimentation separation tank), a primary extractant recovery device (low temperature distillation device), a primary oil-water separator and a primary recovery oil storage device; the outlet of the primary extractor communicates with the inlet of the primary solid-liquid separator, the liquid phase outlet of the primary solid-liquid separator communicates with the first extraction agent recovery device, and the solid phase outlet of the primary solid-liquid separator leads to Subsequent secondary extraction unit; the extractant pipeline of the first extractant recovery device is communicated with the first-stage extractor, and the residual liquid pipeline of the first extrac...

Embodiment 2

[0081] Technical process is identical with embodiment 1, and the process parameter of change mainly is:

[0082] (1) primary extraction

[0083] The metered aged oil is transported to the primary extractor by a pump, and the first extractant is added in proportion. The dosage ratio is 5:1, and the first extractant is a compound of ether and methanol, and the volume ratio of the two is 2:1 in liquid state;

[0084] (2) Secondary extraction

[0085] The primary extraction residue is sent to the secondary extractor with a screw propeller, the second extraction agent is added, the temperature is controlled at 80°C, the reactor pressure is normal pressure, the stirring residence time is 30 minutes, the amount of the second extraction agent and the primary extraction residue The ratio is 3:1, the second extractant is polycyclic aromatic hydrocarbon extract of coal tar, mainly 2-5 ring polycyclic aromatic hydrocarbons, liquid at room temperature, density 0.9-1.2g / cm 3 ;

[0086] ...

Embodiment 3

[0088] Technical process is identical with embodiment 1, and the process parameter of change mainly is:

[0089] (1) One extraction

[0090] The metered aged oil is transported to the primary extractor by a pump, and the first extractant is added in proportion. The dosage ratio is 3:1, the first extractant is the compound of ether and ethanol, and the volume ratio of the two is 3:1 during the liquid state;

[0091] (2) Secondary extraction

[0092] The primary extraction residue is sent to the secondary extractor with a screw propeller, the second extraction agent is added, the temperature is controlled at 80°C, the reactor pressure is normal pressure, the stirring residence time is 30 minutes, the amount of the second extraction agent and the primary extraction residue The ratio is 3:1, the second extractant is polycyclic aromatic hydrocarbon extract of coal tar, mainly 2-5 ring polycyclic aromatic hydrocarbons, liquid at room temperature, density 0.9-1.2g / cm 3 ;

[0093]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com