Application of divalent iron to promoting fermentation of floras for treating organic waste

A ferrous iron and waste technology, applied in biological sludge treatment, solid waste removal, etc., can solve problems such as difficulty in organic waste, efficient waste disposal, and inability to eliminate the odor of organic wastes, and achieves a high level of improvement. The effect of volume reduction rate and shortening fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

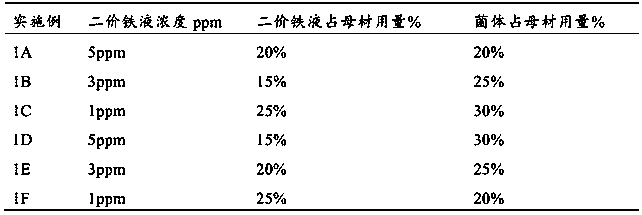

Embodiment 1A~1F

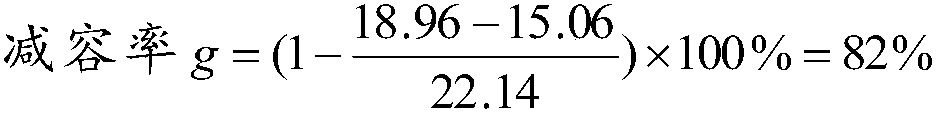

[0017] Mix small pieces of wood and rice husks at a mass ratio of 1:0.5 to obtain the base material used as a fungal bed, a total of 15.06kg, which is 30 times the daily processing capacity. Then add ferrous solution and mix well. Then put into the bacterial population (Sporocytophaga, Rhizopus nigricans, Streptomycetaceac, Pseudomonas, Aspergillus oryzae, Penicillium glaucum, photosynthetic bacteria Rhodopseudomonaspalustris, subtilis Bacillus subtilis, lactic acid bacteria, Candida Albicans), stir well. Add 500 g of sludge from a sewage plant to the above-mentioned parent material containing liquid ferrous iron and bacteria groups, and the moisture content of the sludge is 60%. The humidity of the base metal is between 20-30%, and the temperature is about 10-25 degrees. After 10 hours, check the base metal, and it can be found that a large amount of heat rises in the base metal, and the temperature of the base metal rises to 65 degrees. It can be confirmed by naked eyes an...

Embodiment 2

[0022] Mix small pieces of wood and rice husks at a mass ratio of 1:0.5 to obtain the base material used as a fungal bed, a total of 15.06kg, which is 30 times the daily processing capacity. Then add liquid divalent iron accounting for 20% of the mass of the base material, and mix the liquid divalent iron with a concentration of 5 ppm of the liquid divalent iron. Then put into the bacterial population (Sporocytophaga, Rhizopus nigricans, Streptomycetaceac, Pseudomonas, Aspergillusoryzae, Penicillium glaucum, photosynthetic bacteria Rhodopseudomonaspalustris, Bacillus subtilis Bacillus subtilis, lactic acid bacteria, Candida Albicans), the thalline accounts for 20% of the mass of the base material, and is stirred and mixed. Add 500 g of sludge from a sewage plant to the above-mentioned parent material containing liquid ferrous iron and bacteria groups, and the moisture content of the sludge is 60%. The humidity of the base metal is between 20-30%, and the temperature is about ...

Embodiment 3

[0025] Mix wood chips and sawdust at a mass ratio of 1:1 to obtain 15.06 kg of base material, which is 30 times the daily processing capacity. Then add liquid ferrous iron with a concentration of 5ppm, which accounts for 30% of the mass of the base material, and mix well. Re-enter the bacterial population (Sporocytophaga, Rhizopus nigricans, Streptomycetaceac, Pseudomonas, Aspergillus oryzae, Penicillium glaucum, photosynthetic bacteria Rhodopseudomonaspalustris, subtilis Bacillus subtilis, lactic acid bacteria, Candida Albicans), the thalline accounts for 25% of the mass of the base material, and is stirred and mixed. Add 500 g of sludge from a sewage plant to the above-mentioned parent material containing liquid ferrous iron and bacteria groups, and the moisture content of the sludge is 60%. The humidity of the base material is between 20% and 30%, and the temperature is about 10-25 degrees. After 10 hours, the base metal was inspected, and it was found that a large amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com