Blue-green alga mud deep-dehydration method based on thermal rearrangement of capsular polysaccharide soft lattices

A capsular polysaccharide and deep dehydration technology, applied in the field of environmental engineering, can solve the problems of increasing the difficulty of filtrate treatment, adding more types of drugs, and cumbersome pre-treatment, etc., to achieve the effects of expanding utilization channels, improving quality, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

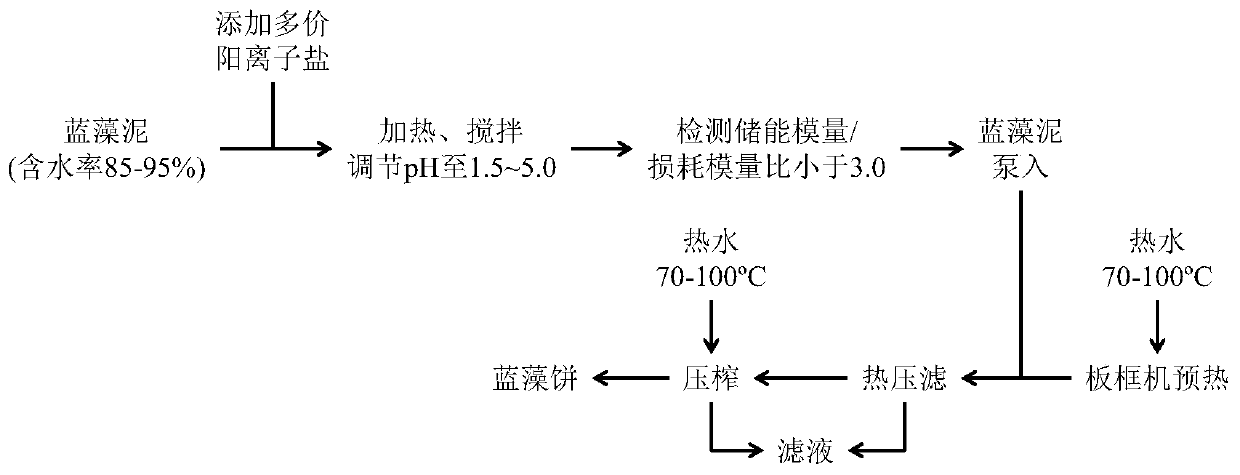

Method used

Image

Examples

Embodiment 1

[0028] Get 1.0 tons of fresh cyanobacteria mud with a water content of 90% (w / v), VS / TS as 91% in the stirring device, add 10kg of iron sulfate, that is, the amount of iron sulfate input is 10% (wt) of the cyanobacteria dry matter weight at this time. ). Use water vapor to heat the blue-green algae mud to 80°C, adjust the pH to 2.5, and stir for 30 minutes with a mixer. Take a sample and test the storage modulus and loss modulus under the corresponding temperature conditions, and confirm that the ratio of the two is less than 3.0. If it is higher than 3.0, add the amount of ferric sulfate, stir and mix, so that the storage modulus / loss modulus is less than 3.0 .

[0029] At the same time, pump 80°C circulating hot water into the unloaded diaphragm plate and frame filter press, filter out the hot water and return it to the hot water tank, preheat the diaphragm plate and frame filter press and stand by.

[0030] After the cyanobacteria slurry is stirred, it is pumped into a di...

Embodiment 2

[0035] Get 0.65 tons of fresh blue-green algae mud with a water content of 85% (w / v) and a VS / TS of 91%. Add 13kg of ferric chloride, that is, the dosage of ferric chloride is 13.3% (wt) of the dry matter weight of cyanobacteria. Use steam to heat the blue-green algae mud to 85°C, adjust the pH to 2.0, and use a mixer to stir for 25 minutes. Take samples and detect the storage modulus and loss modulus under corresponding temperature conditions, and confirm that the ratio of the two is less than 3.0. If it is higher than 3.0, adjust the pH value to 1.0-1.5, stir and mix well, so that the storage modulus / loss modulus is less than 3.0.

[0036] At the same time, pump 85°C circulating hot water into the unloaded filter press, filter out the hot water and return it to the hot water tank, preheat the filter press and stand by.

[0037] After the cyanobacteria slurry is stirred, it is pumped into a diaphragm plate and frame filter press for pressure filtration. After the feed press...

Embodiment 3

[0042] Get 1.6 tons of fresh blue-green algae mud with a water content of 94% (w / v) and a VS / TS of 91%. Add 6kg of aluminum sulfate, that is, the dosage of aluminum sulfate at this time is 6.25% (wt) of the dry matter weight of cyanobacteria. Use steam to heat the blue-green algae mud to 90°C, adjust the pH to 2.0, and use a mixer to stir for 20 minutes. Take samples and detect the storage modulus and loss modulus under corresponding temperature conditions, and confirm that the ratio of the two is less than 3.0. If it is higher than 3.0, supplement the amount of ferric sulfate, stir and mix, so that the storage modulus / loss modulus is less than 3.0.

[0043] At the same time, pump 90°C circulating hot water into the unloaded filter press, filter out the hot water and return it to the hot water tank, preheat the diaphragm plate and frame filter press and stand by.

[0044] After the cyanobacteria slurry is stirred, it is pumped into a diaphragm plate and frame filter press fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com