Method for treating industrial organic waste through double-wave cracking

A technology for organic waste and pyrolysis treatment, applied in the field of double-wave pyrolysis treatment of industrial organic waste, to achieve the effect of low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

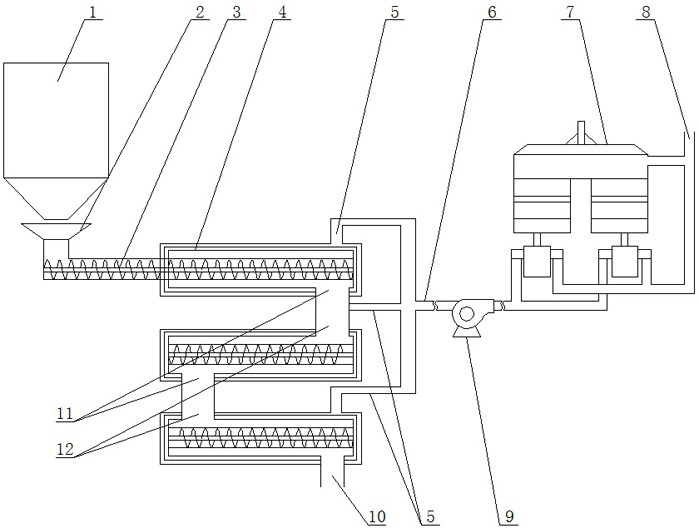

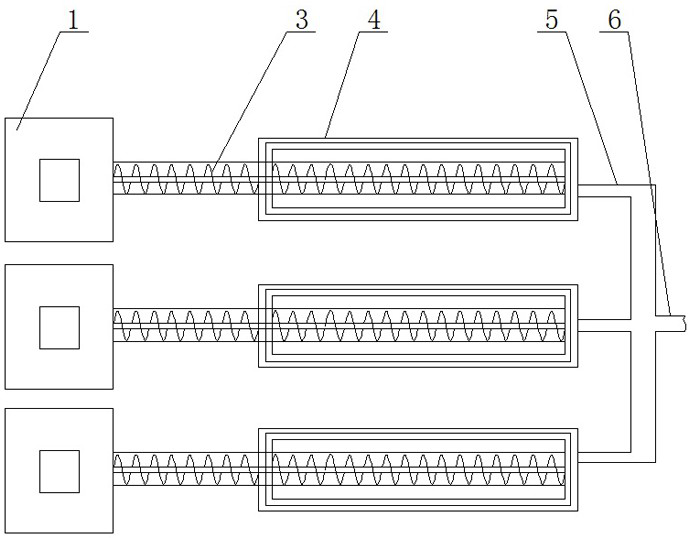

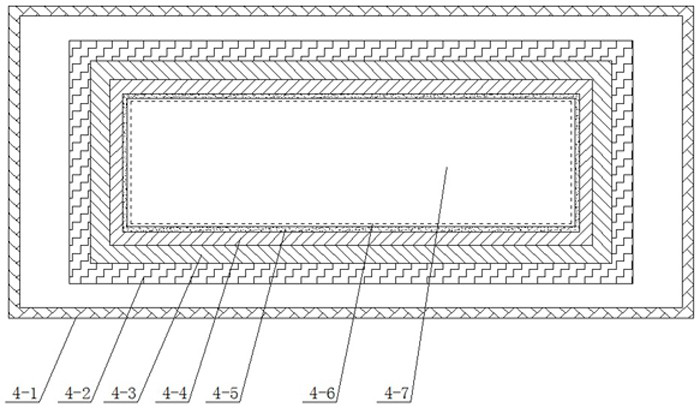

[0029] Example 1, the present invention provides a dual-wave pyrolysis device for industrial organic waste. The waste tank (1) is connected to the feed port (2), and the feed port (2) is connected to the pyrolysis chamber (4) through a pipeline. The chamber (4) is provided with a screw propeller (3); there are 9 cracking chambers (4), which are arranged in three vertical and three horizontal directions, and the three longitudinally arranged cracking chambers (4) form a group and are connected in series. That is, the discharge port (11) of the upper cracking chamber (4) is connected to the feed port (12) of the lower cracking chamber (4), and a cracking gas outlet (5) is arranged above the cracking chamber (4), and the bottom cracking chamber ( The lower end of 4) is provided with a residue outlet (10); the three groups of cracking chambers are connected in parallel, and the cracking gas outlets (5) of the nine cracking chambers are all connected to the cracking gas collection p...

Embodiment 2

[0035] Embodiment 2, the present invention provides a kind of method of double-wave pyrolysis processing industrial organic waste, comprises the following steps:

[0036] S1 pretreatment, dehydration or crushing of industrial organic waste;

[0037] S2 thermal cracking, the industrial organic waste residue or waste liquid obtained by pretreatment is continuously sent into the cracking chamber of the double wave cracking device through the feed port, and under microwave irradiation, the thermal cracking effect of microwave is used to remove the organic waste in the organic waste Large molecules are split into small organic molecules and polar and non-polar substances, such as H 2 S, CH 4 etc., the cracking temperature can reach 600-800°C;

[0038]S3 catalytic cracking, after thermal cracking, microwave cracking enters the microwave catalytic cracking stage, through the polarization of microwaves, the polar bonds of polar substances are oscillating, twisting, and activated uns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com