A low-medium radioactive waste treatment device

A waste treatment and low-radioactivity technology, which is applied in the field of waste treatment devices and medium-low radioactive waste treatment devices, can solve the problems of occupying large nuclear waste yard space, etc., and achieve good economic benefits, reliable principles, and high volume reduction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

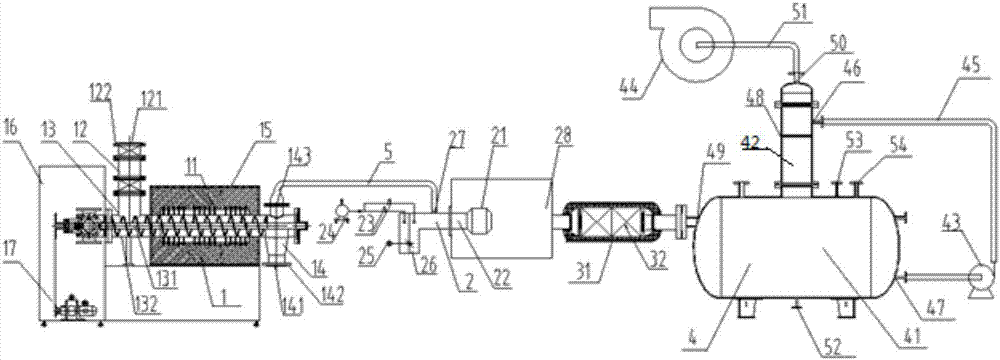

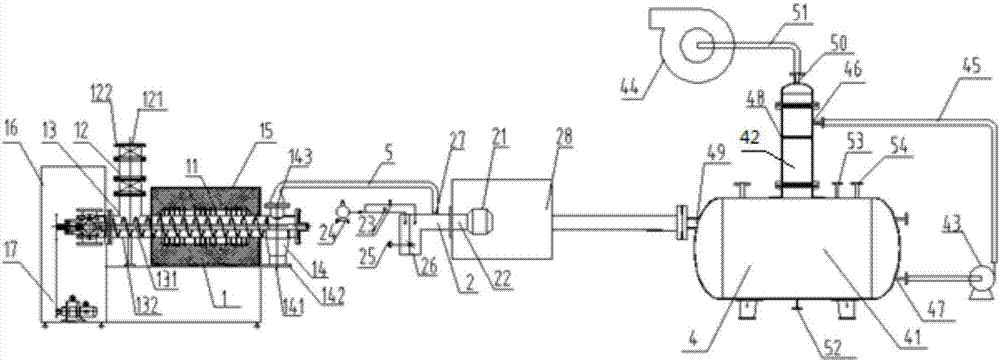

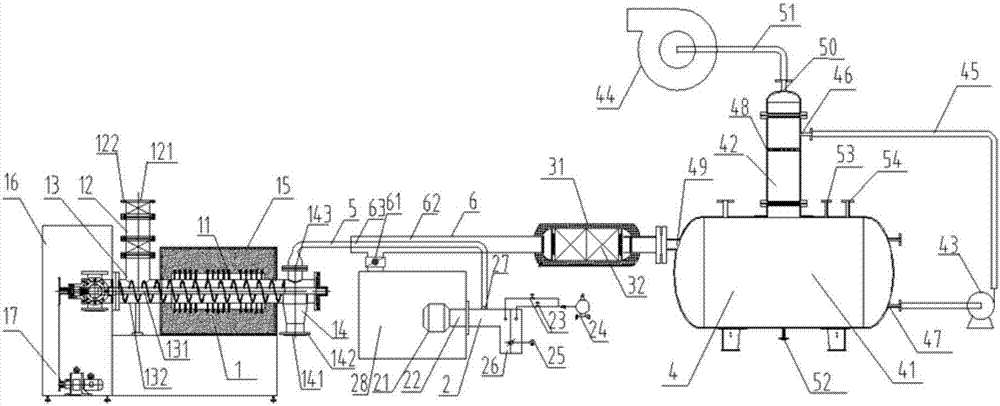

[0030] The main structure of the medium and low radioactive waste treatment device involved in this embodiment includes a pyrolysis reactor 1, a burner 2, a catalytic converter 3, a spray water washing tower 4 and a high temperature resistant pipeline 5, a pyrolysis reactor 1, a burner 2. The catalytic converter 3 and the spray washing tower 4 are connected through a high-temperature resistant pipeline 5. The pyrolysis reactor 1 includes a heating device 11, a closed feed system 12, a screw propeller 13, a closed discharge system 14, an electric Heating furnace 15, first temperature controller 16 and motor 17, closed feed system 12 includes feed inlet 121 and sealed feed valve 122, screw propeller 13 includes worm screw 131 and feed pipe 132, and closed discharge system 14 includes Solid residue outlet 141, sealed discharge valve 142 and gas outlet 143; the burner 2 includes a combustion head 21 and a burner body 22, and the burner body 22 includes a two-stage solenoid valve 23...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the structure of the catalytic converter 3 is omitted, and the output end of the burner 2 communicates with the second air inlet 49 of the spray water washing tower 4 through the high temperature resistant pipeline 5 .

Embodiment 3

[0046]The difference between this embodiment and Embodiment 1 is: the structure of the heat exchanger 6 is added, the heat exchanger 6 is a high temperature resistant pipeline 62 with a control valve 61, and the input end of the heat exchanger 6 communicates with the exhaust gas outlet of the burner 2 , the output end of the heat exchanger 6 communicates with the catalytic converter 3, and the high-temperature resistant pipeline 62 of the heat exchanger 6 is spirally arranged on the outside of the gas inlet pipeline 63 of the burner 2, through which the high-temperature resistant pipeline 62 makes the burned The high-temperature tail gas exchanges heat with the gas at the burner 2 inlet; the difference between its processing steps and embodiment 1 is step (2), before starting the burner 2, the control valve 61 of the burner 2 tail gas outlet is opened to realize the burner 2 tail gas and The heat exchange of the inlet gas increases the temperature of the inlet gas of the burner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com