A thermochemical treatment method for low and medium radioactive waste

A technology for thermochemical treatment and waste, which is applied in the field of medium and low radioactive waste treatment equipment and thermochemical treatment of low and medium radioactive waste. It can solve the problem of increasing combustion air turbulence, increasing the burden and difficulty of flue gas post-treatment purification system, and increasing energy consumption. Pyrolysis products and other issues, to achieve the effect of reducing volume, reducing nuclear radiation pollution and the atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

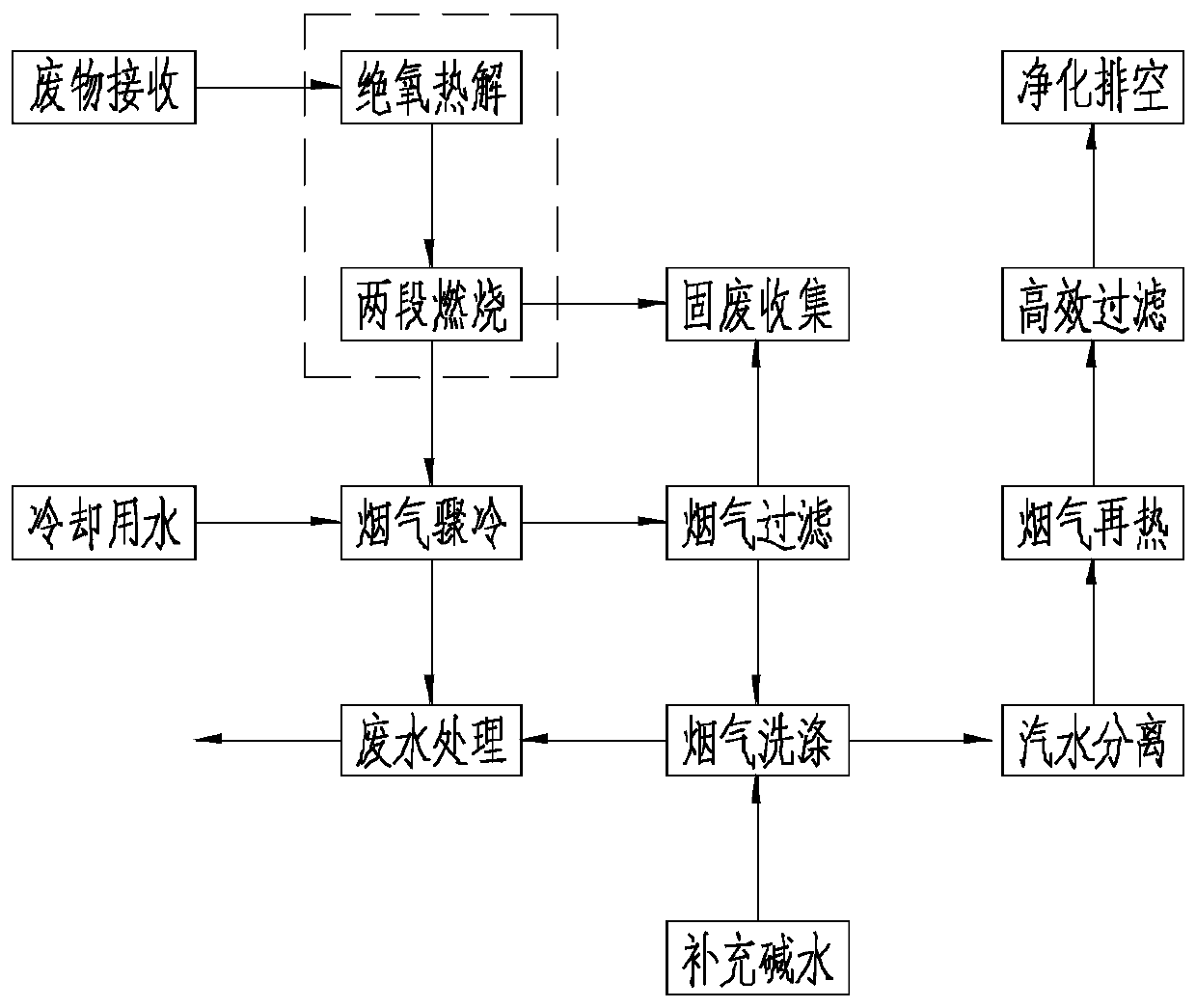

[0030] The specific process steps of the low-level combustible solid waste treatment method in the staged thermochemical treatment involved in this embodiment are:

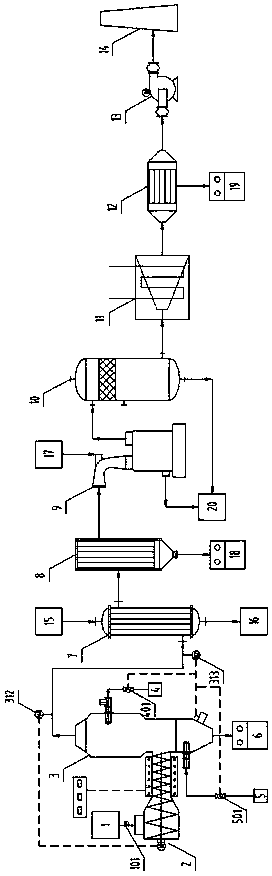

[0031] Step1, start each device: In order to ensure that the entire process is operated under negative pressure, first start the power unit 13, start the flue gas quenching device 7, the flue gas filtering device 8, the flue gas washing device 9, the steam-water separation device 10, Flue gas reheating device 11, high efficiency filter device 12 and first wastewater treatment device 16;

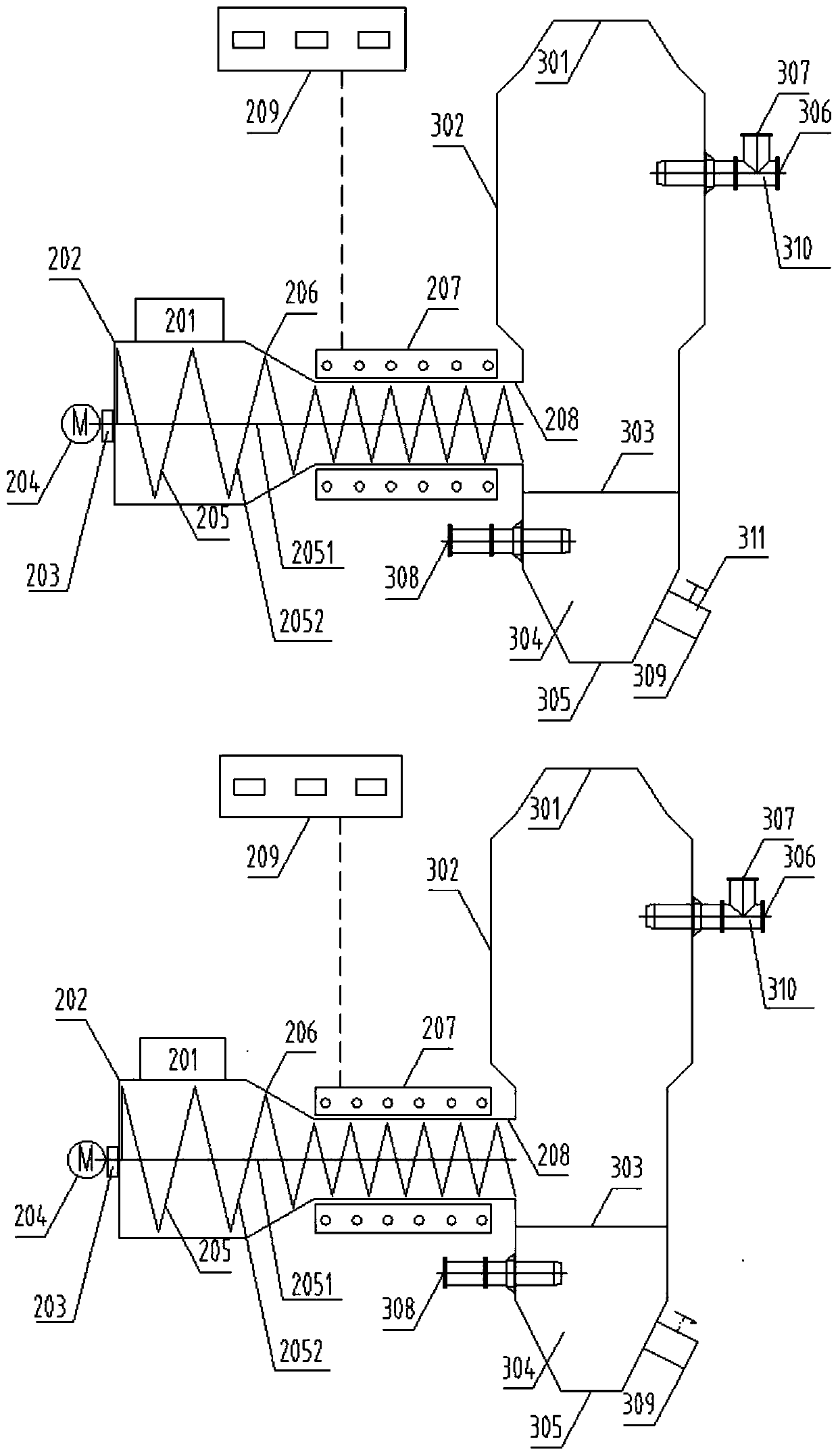

[0032] Step2, start the pyrolysis temperature: start the drive motor 204, set the pyrolysis temperature, turn on the heating mode of the pyrolysis device, use the heating device 207 to heat the pyrolysis delivery section 208, and the temperature controller 209 sets the temperature of the heating device 207 to 400°C;

[0033] Step3, start the combustion device: then start the gas-liquid combustion-supporting burner 306 in the gas-...

Embodiment 2

[0044] The difference between this implementation and Example 1 is: the temperature of the heating device 207 is set at 600°C in Step2; The gas is rapidly cooled to 150°C in the flue gas quenching device 7;

[0045] The ratio of the diameter of the gas-liquid combustion chamber to the diameter of the solid combustion chamber in the device for treating low-medium level combustible solid waste by this method is 2.2.

Embodiment 3

[0047] The difference between this implementation and Example 1 is: the temperature of the heating device 207 is set at 500°C in Step2; The gas is rapidly cooled to 100°C in the flue gas quenching device 7;

[0048] The ratio of the diameter of the gas-liquid combustion chamber to the diameter of the solid combustion chamber in the device for treating low-level and medium-level combustible solid waste by this method is 1.2, the equipment is more compact, and the floor space is small, which is suitable for projects with limited land use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com