Film made from graphene-carbon nanotube composite material and preparation method of film

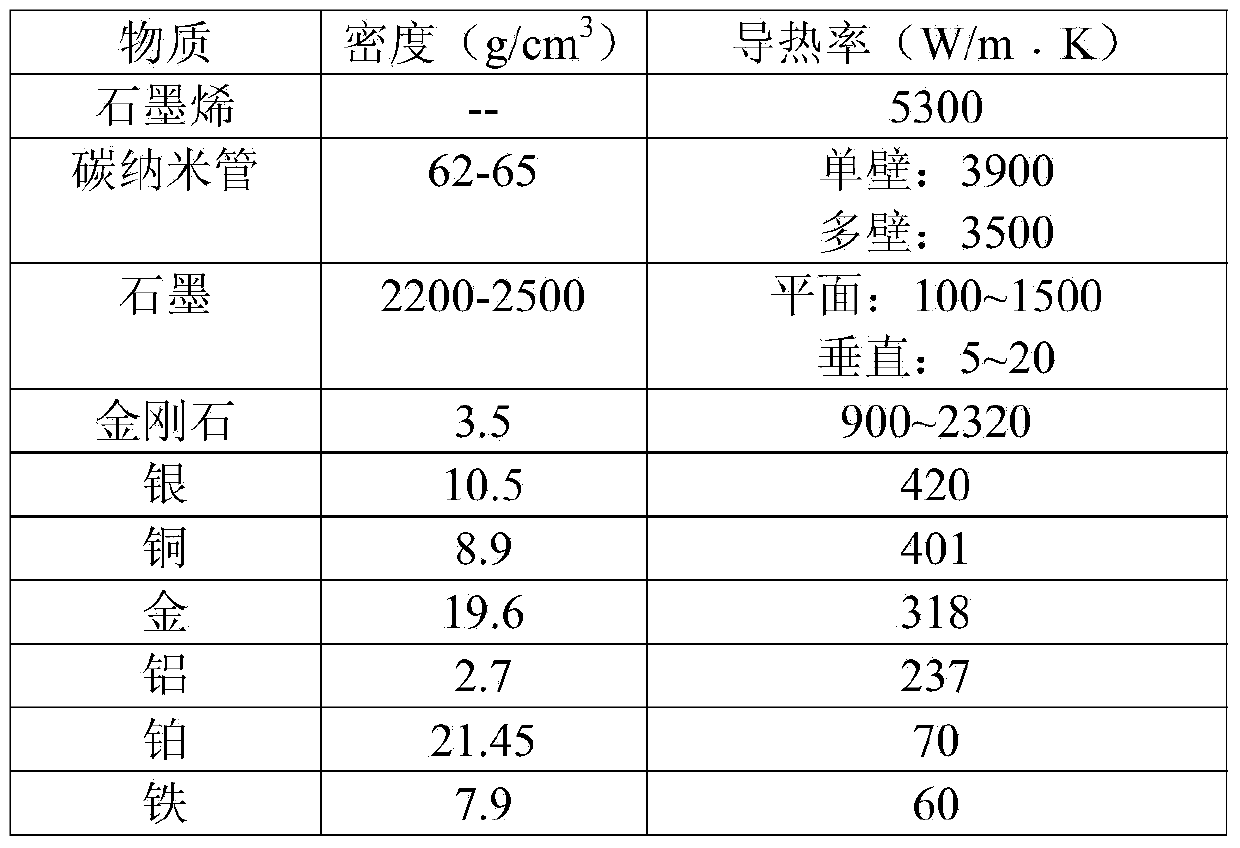

A technology of composite film and carbon nanotubes, which is applied in the field of preparation and application of nanocomposite materials, to achieve the effects of improving the overall thermal conductivity, increasing composite strength, and improving the uniformity and flatness of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of reduced graphene solution: at 25°C, measure 20 mL of DMF as a dispersion solvent, weigh 0.1 g of reduced graphene, and obtain a uniformly dispersed reduced graphene solution by mechanical stirring and ultrasound;

[0036](2) Preparation of single-walled carbon nanotube solution: at 25°C, measure 20 mL of DMF as a dispersing solvent, weigh 0.1 g of single-walled carbon nanotube, and obtain a uniformly dispersed single-walled carbon nanotube solution by mechanical stirring and ultrasonication ;

[0037] (3) Mix the two solutions obtained in the above (1) and (2), wherein the concentration of reduced graphene is 0.05 mg / mL, and the concentration of single-walled carbon nanotubes is 0.05 mg / mL, and the solution is stirred and ultrasonically dispersed to obtain Uniformly dispersed reduced graphene-single-walled carbon nanotube mixed solution;

[0038] (4) Put the mixed solution obtained in the above (3) into a polytetrafluoroethylene-lined reaction kettle...

Embodiment 2

[0042] (1) Preparation of graphene oxide solution: at 25°C, measure 20 mL of DMF as a dispersion solvent, weigh 0.1 g of graphene oxide, and obtain a uniformly dispersed graphene oxide solution by mechanical stirring and ultrasonication;

[0043] (2) Preparation of single-walled carbon nanotube solution: at 25°C, measure 20 mL of dispersing solvent DMF / hydroquinone (v / v=1 / 1), weigh 0.2 g of single-walled carbon nanotubes, and Stirring and ultrasonication to obtain a uniformly dispersed single-walled carbon nanotube solution;

[0044] (3) Mix the two solutions obtained in (1) and (2) above, wherein the concentration of graphene oxide is 0.05 mg / mL, and the concentration of single-walled carbon nanotubes is 0.1 mg / mL, and disperse by stirring and ultrasonication. Obtain a uniformly dispersed graphene oxide-single-walled carbon nanotube mixed solution;

[0045] (4) Put the mixed solution obtained in the above (3) into a polytetrafluoroethylene-lined reaction kettle. In the heati...

Embodiment 3

[0049] (1) Preparation of graphene oxide solution: at 25°C, measure 20 mL of dispersing solvent DMF / hydroquinone (v / v=1 / 1), weigh 0.1 g of graphene oxide, stir mechanically and ultrasonically, Obtain a uniformly dispersed graphene oxide solution;

[0050] (2) Preparation of multi-walled carbon nanotube solution: at 25°C, measure 20 mL of dispersing solvent DMF / hydroquinone (v / v=1 / 1), weigh 0.2 g of multi-walled carbon nanotubes, and Stirring and ultrasonication to obtain a uniformly dispersed multi-walled carbon nanotube solution;

[0051] (3) Mix the two solutions obtained in the above (1) and (2), wherein the concentration of graphene oxide is 0.05 mg / mL, and the concentration of multi-walled carbon nanotubes is 0.1 mg / mL. Stir and ultrasonically disperse to obtain Uniformly dispersed graphene oxide-multi-walled carbon nanotube mixed solution;

[0052] (4) Put the mixed solution obtained in the above (3) into a polytetrafluoroethylene-lined reaction kettle. In the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com