Degradable resin pellet and molded product using same

A technology for degrading resin and molded products, applied in the field of degradable resin particles and molded products using them, can solve the problems of low resin demand properties of natural polymers, high manufacturing cost, lack of economic benefits, etc., and achieve excellent processability. , excellent flexibility, the effect of improving the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

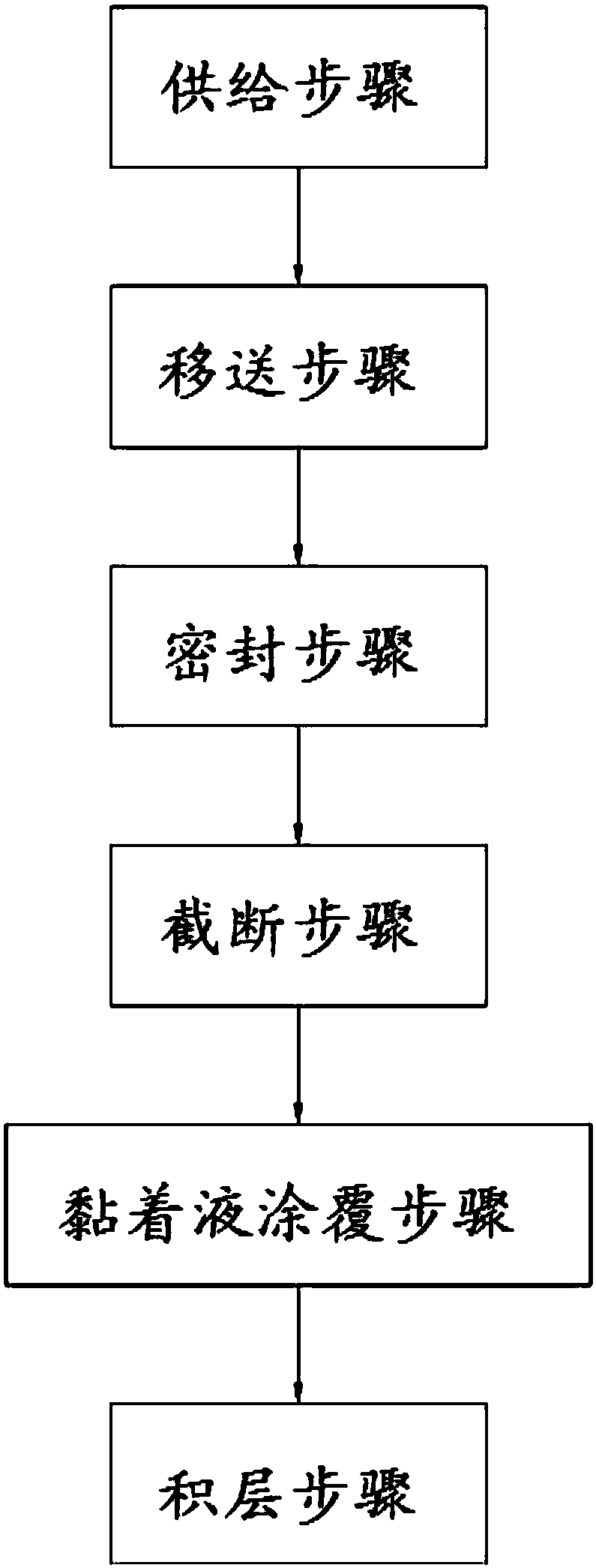

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below.

[0037] The present invention provides a kind of degradable resin particle, and it comprises following composition and is made: polylactic acid (PLA), calcium carbonate (CaCO 3 ), magnesium, aluminum, silicon, calcium.

[0038] In addition, the present invention provides a molded article utilizing degradable resin particles made of the following components: polylactic acid (PLA), calcium carbonate (CaCO 3 ), magnesium, aluminum, silicon, calcium.

[0039] The molded product refers to a product such as a thin vinyl bag such as a measuring garbage bag, a plastic bag, or a plastic bag.

[0040] The present invention, preferably, provides a kind of degradable resin particle, and it is made in the following way: In polylactic acid (PLA) 100 weight parts, comprise calcium carbonate (CaCO 3 ) 50 to 150 parts by weight, magnesium 0.1 to 10 parts by weight, aluminum 0.1 to 10 parts by weight, silicon 0.1 to 10 parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com