Titanium alloy equal-thickness thin-wall special-shaped annular piece rolling and expanding composite forming method

A compound forming and special-shaped ring technology, applied in metal rolling and other directions, can solve the problems of low precision, poor performance, and low material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

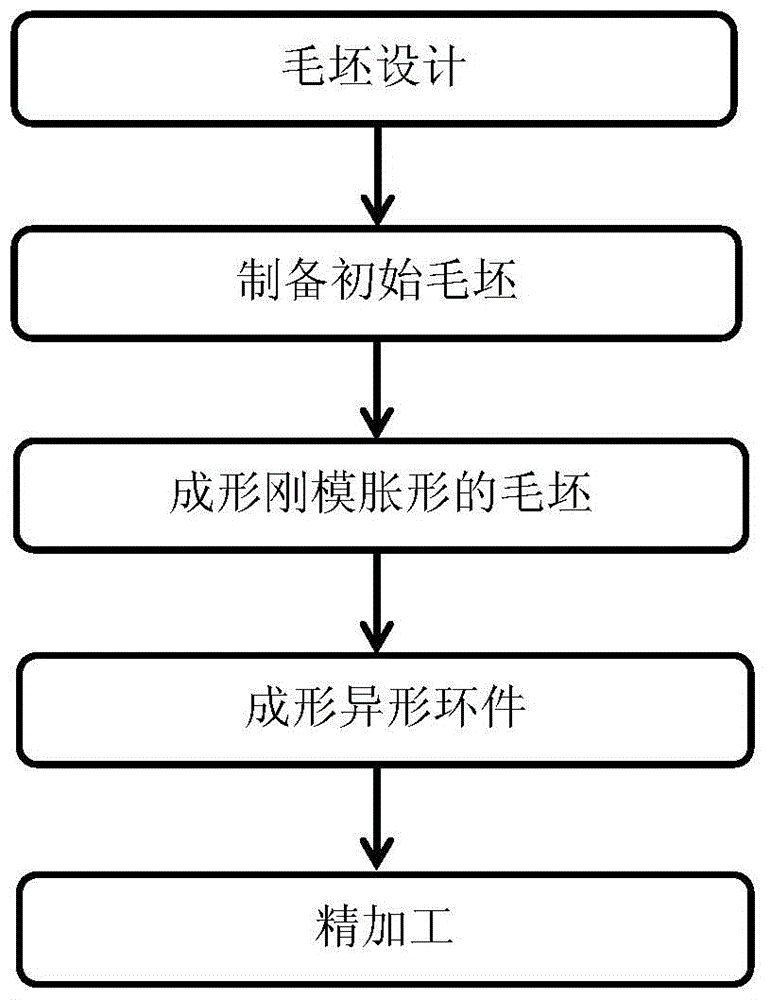

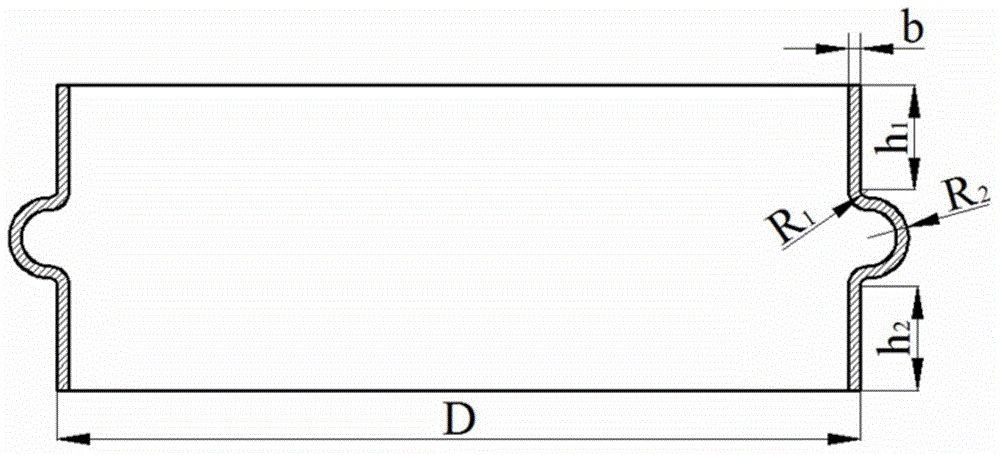

[0058] This embodiment is a composite forming process of titanium alloy rolling and expanding such as image 3 method of the ring shown.

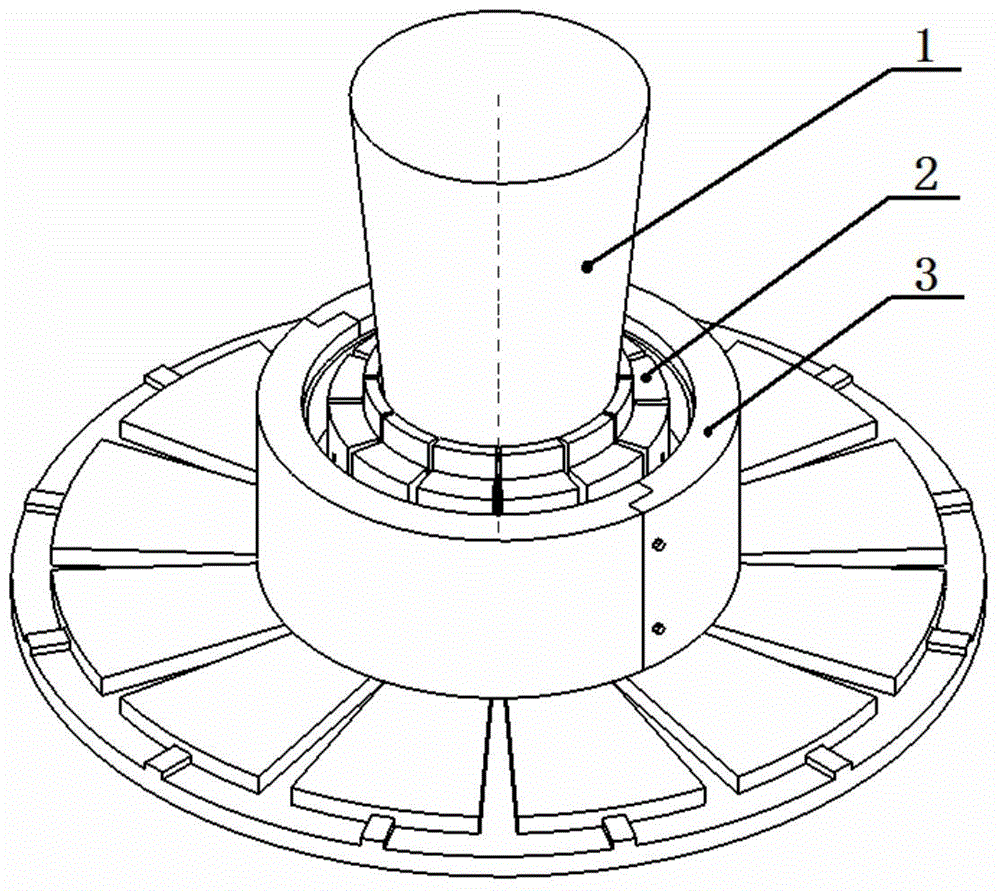

[0059] When the special-shaped ring is formed by the rolling-expansion composite forming process, the bulging die disclosed in the invention with the application number 201510197511.1 is used. The bulging mold includes a mandrel 1, n supports, n punches 2, dies 3 and a base; n slide rails are evenly distributed on the upper surface of the base, and the direction of each slide rail is the direction of the base. Radially; the chute on the lower surface of each bracket is respectively fitted with the slide rails on the upper surface of the base to form a circular assembly; the small diameter end of the conical mandrel is located in the assembly, and The inner surfaces of each bracket are attached; the distance between the lower end surface of the mandrel and the upper surface of the base is 1 / 3 of the vertical height of the bracket; n punches...

Embodiment 2

[0111] This embodiment is a composite forming process of titanium alloy rolling and expanding such as Figure 4 method of the ring shown.

[0112] When the special-shaped ring is formed by the rolling-expansion composite forming process, the bulging die disclosed in the invention with the application number 201510197511.1 is used. The bulging mold includes a mandrel 1, n supports, n punches 2, dies 3 and a base; n slide rails are evenly distributed on the upper surface of the base, and the direction of each slide rail is the direction of the base. Radially; the chute on the lower surface of each bracket is respectively fitted with the slide rails on the upper surface of the base to form a circular assembly; the small diameter end of the conical mandrel is located in the assembly, and The inner surfaces of each bracket are attached; the distance between the lower end surface of the mandrel and the upper surface of the base is 1 / 3 of the vertical height of the bracket; n punche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com