Fixing part connected with photo frame backboard and manufacturing method of fixing part

A technology of backplane connection and fixing parts, which is applied in the direction of fasteners, picture frames, applications, etc., can solve the problem of the consistency of the connection of the fixing parts, the consistency of the tightness of the connection of the difficult fixing parts, the difficulty of firm connection and flexibility Rotation and other problems, to achieve the effect of material saving, good processing stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

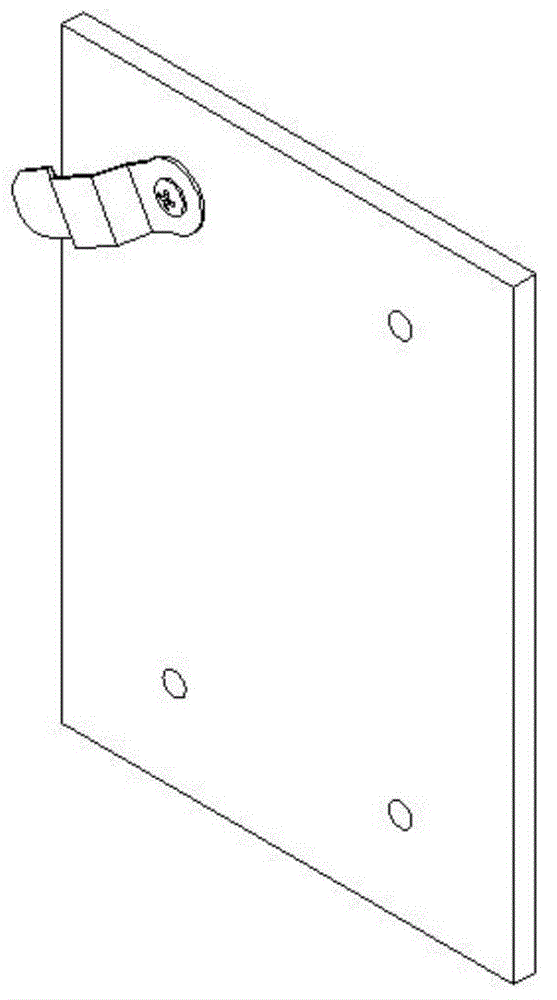

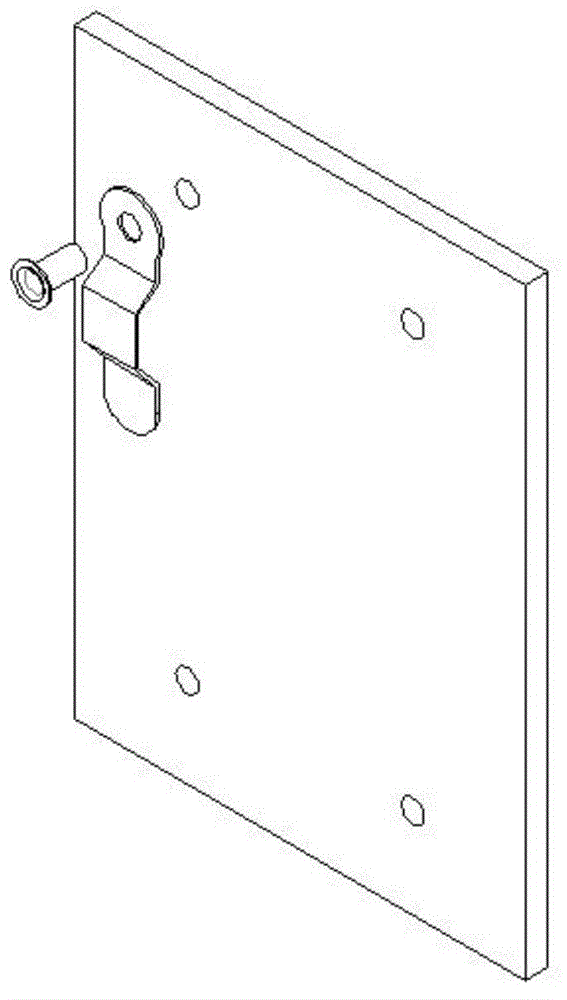

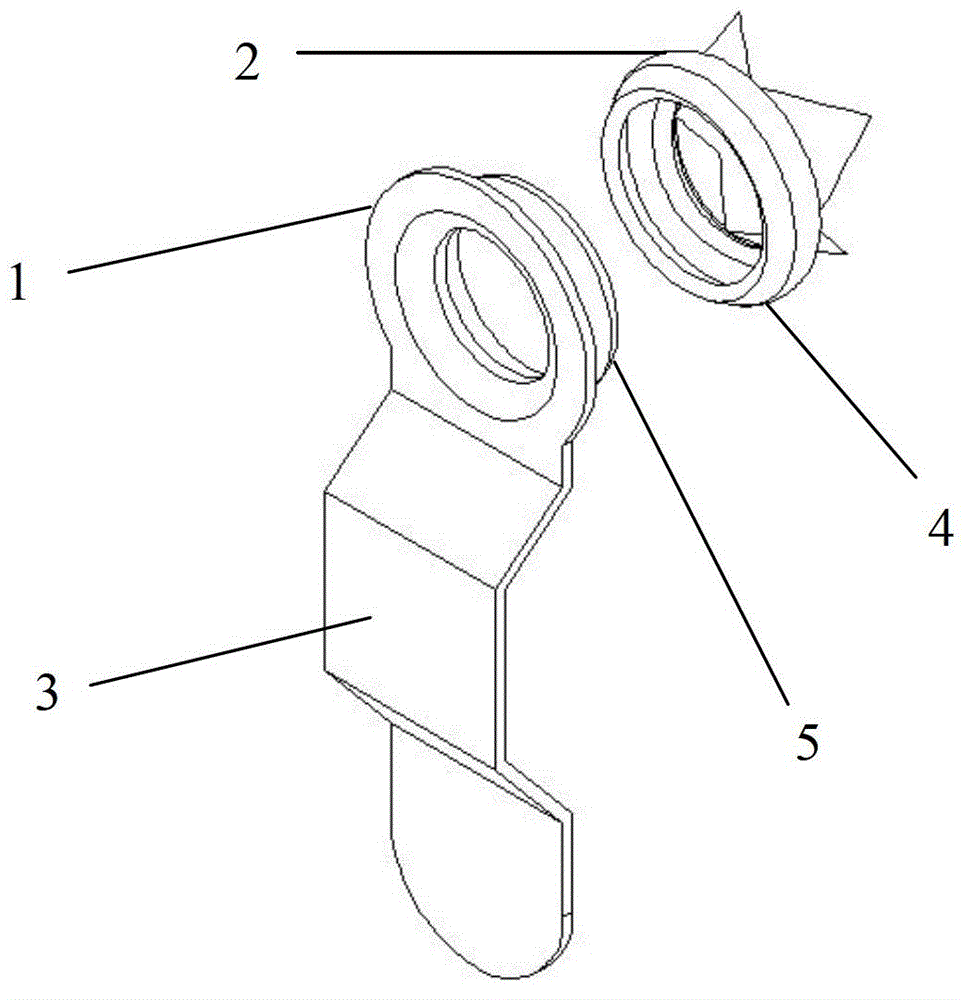

[0047] image 3 A specific embodiment of the present invention is shown, by image 3 It can be seen that the fixing part used to connect with the photo frame backboard includes a rotating part 1 and a fixing part 2 connected with the photo frame, one end of the rotating part 1 is connected with the fixing part 2, and the other end is connected with a fixing part for fixing the photo frame. The base body 3 is connected; the rotating part 1 is formed by the embedded connection of the concave rotating surface 4 and the convex rotating surface 5; the concave rotating surface 4 is a concave groove in the ring, and the convex rotating surface 5 is a ring flange. In this combined form, the two rotating surfaces are all in the shape of a complete ring.

[0048] The concave rotating surface 4 of the rotating part 1 is connected to the fixed part 2, the convex rotating surface 5 is connected to the fixed base 3, the convex rotating surface 5 is embedded in the concave rotating surface ...

Embodiment 2

[0054] Figure 5 Another specific structure of the present invention is shown, by Figure 5 It can be seen that this embodiment is the same as Embodiment 1 except for the following features: the concave rotating surface connected with the spikes is a two-section arc concave groove 7 . This form of rotating surface is not a complete ring shape, which can save materials relatively. In addition, if there is debris or dirt that hinders relative rotation between the two rotating surfaces, this structural form is also convenient for removing debris or dirt from Gap discharge between arcs.

Embodiment 3

[0056] Figure 6 Another specific structure of the present invention is shown, by Figure 6 It can be seen that this embodiment is the same as Embodiment 2 except for the following features: the concave rotating surface connected with the spikes is a three-segment arc concave groove 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com