Solid rocket engine lining forming rotating tool

A technology of solid rockets and motors, which is applied to workbenches, manufacturing tools, etc. It can solve the problems of difficult positioning of screw holes and heavy tooling, and achieve the effect of simple structure, uniform lining thickness and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

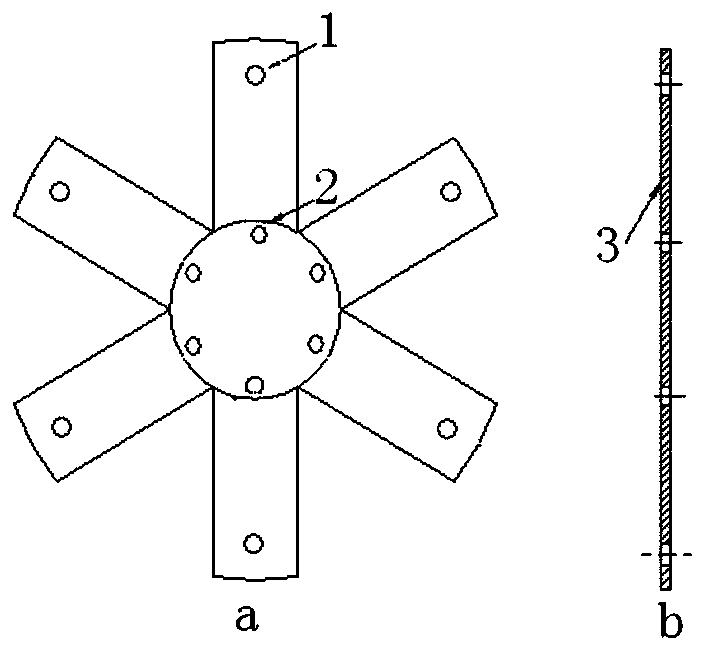

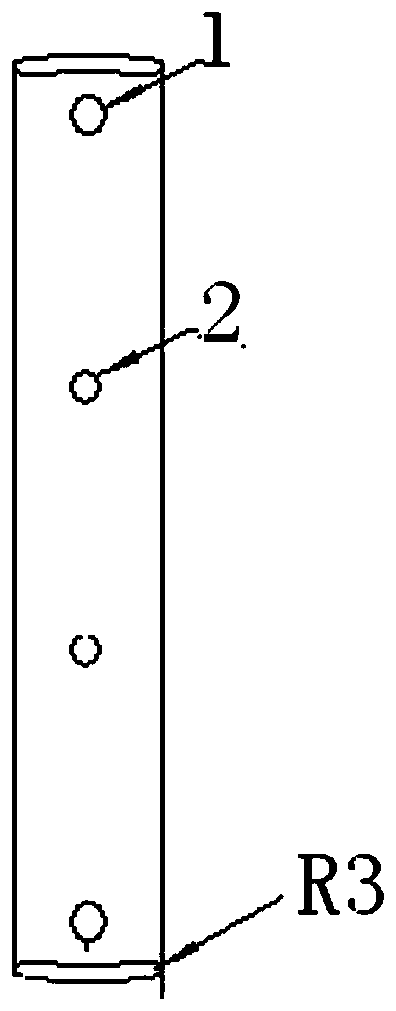

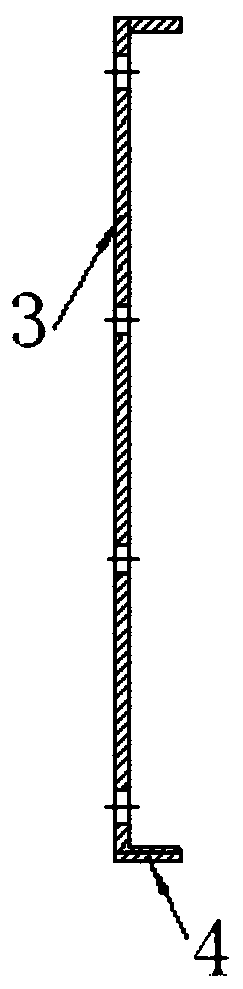

[0023] This embodiment is a solid rocket motor liner forming rotary tooling. The liner forming rotary tooling 3 is lath-shaped, and at both ends of the liner forming rotary tooling there are shell clips 4 bent toward the cylindrical surface of the outer surface of the shell, such as figure 2 shown. The axial length of the shell clamping plate is 25mm. Both the inner surface and the outer surface of the clamping plate are arc surfaces, and the radius R3 of the arc surface is the same as the radius of the outer peripheral surface of the housing 7 . Two housing skirt frame installation holes 1 with a diameter of 12 mm and two universal joint installation through holes 2 with a diameter of 10 mm are distributed on the tooling, and the two housing skirt frame installation holes are respectively located at the The seam covers the two ends of the frock so that the two universal joint installation through holes are located between the two housing skirt frame installation holes. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com