Automatic sawing, punching and milling machining equipment for aluminum templates

A technology for processing equipment and aluminum formwork, applied in the field of automatic sawing, punching and milling processing equipment for aluminum formwork, can solve the problems of poor consistency of product quality, high labor intensity of workers, low degree of automation, etc., and achieves improved production efficiency, reasonable process connection and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

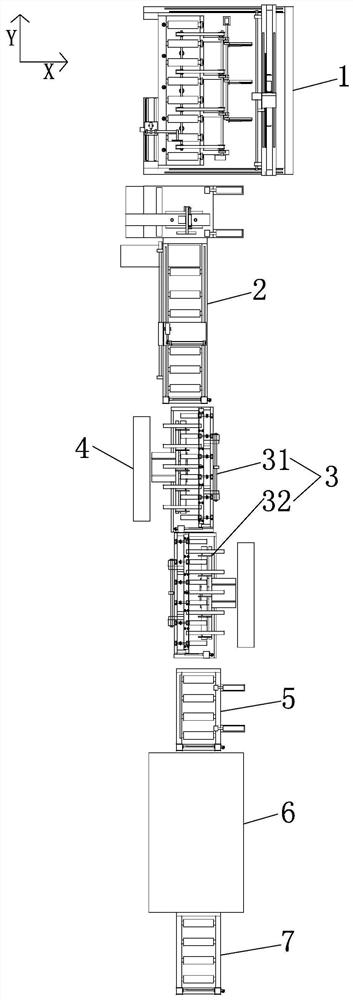

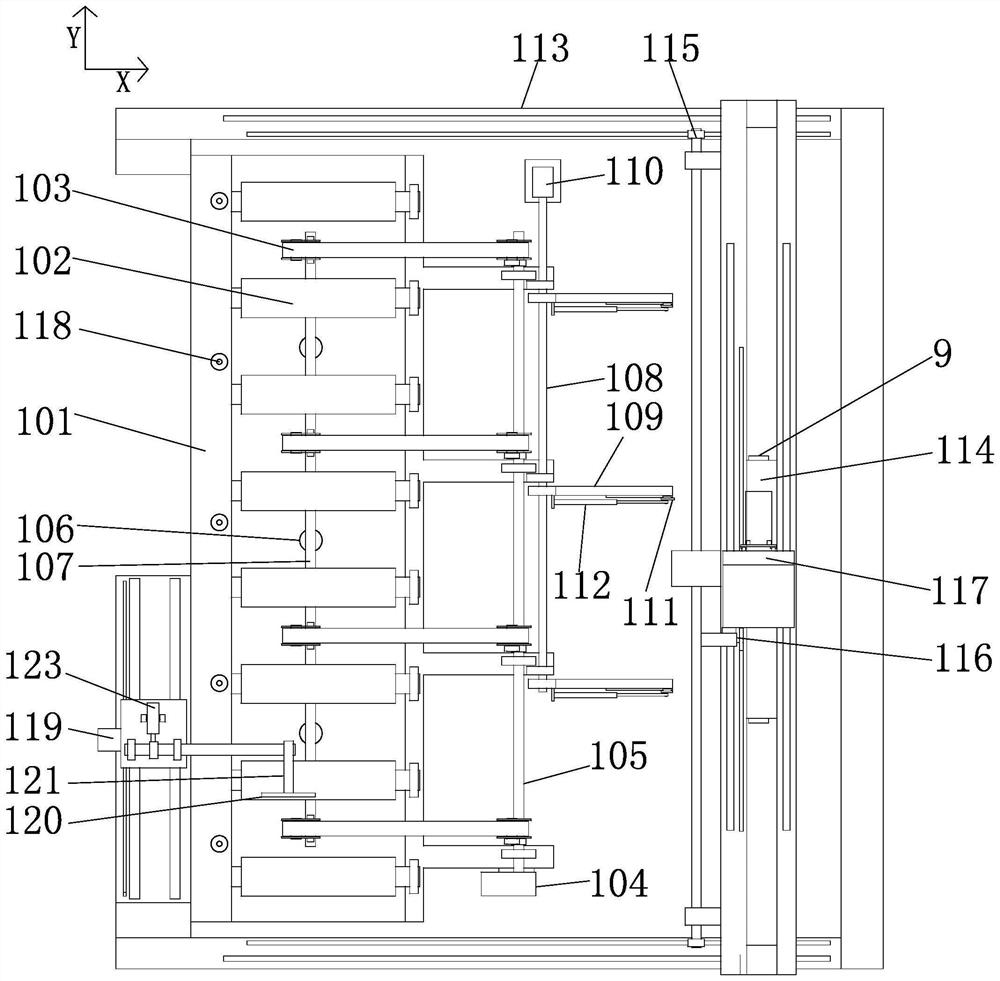

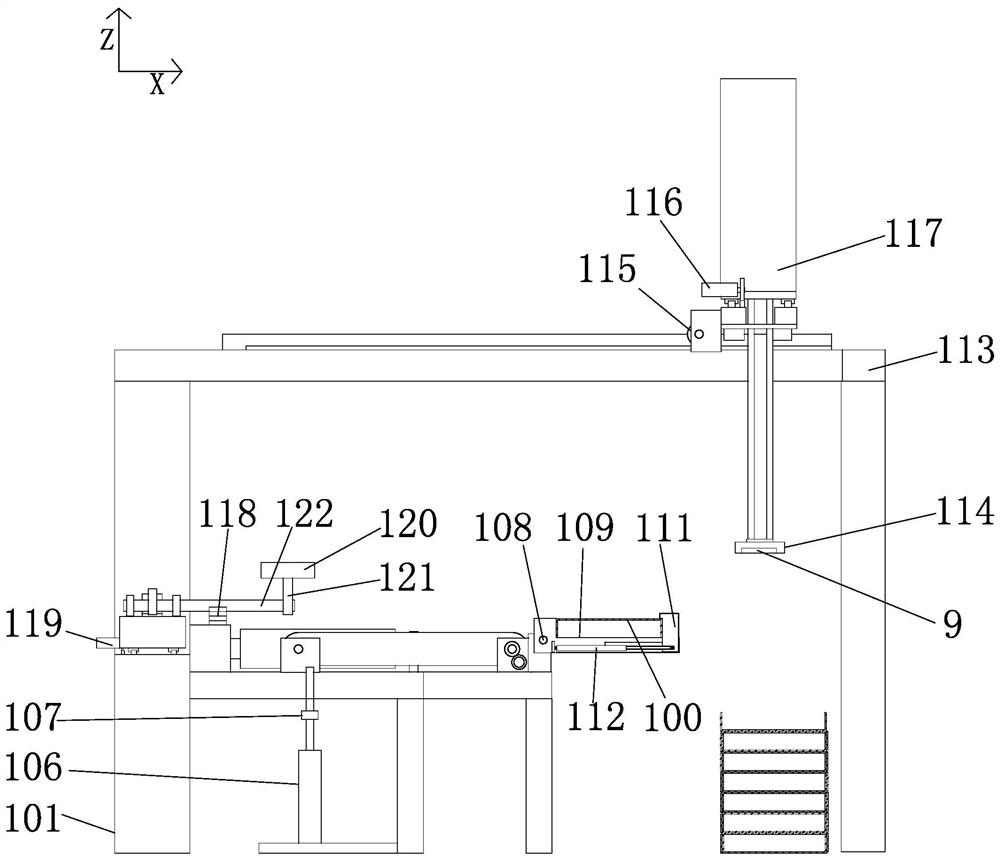

[0044] refer to Figure 1-18 , an aluminum template automatic saw punching and milling processing equipment, comprising a cutting and feeding unit 1, a cutting unit 2, a row punching and feeding unit 3, a row and punching unit 4, a row and milling feeding unit 5, a row and milling unit 6, a row and milling unit Milling and blanking unit 7; material cutting and loading unit 1, used to transport aluminum template 100 to material cutting unit 2; Receive the aluminum template 100 conveyed by the cutting and feeding unit 1 and saw the aluminum template 100 to a fixed length; After the side is turned upside down, it is sent to the row punching unit 4 for punching p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com