Welding device for side sealing plate barb of switch cabinet

A welding device and switchgear technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of laborious welding and poor welding quality, and achieve the effect of good connection strength and good quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

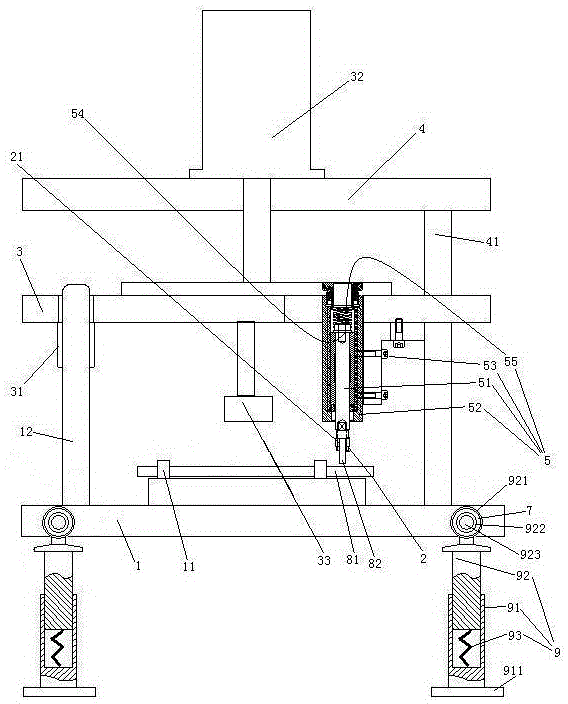

[0028] Embodiment one, see figure 1 , a barb welding device for the side sealing plate of a switchgear, including a support column 9, a lower seat 1, a conductive block 33, a suspension plate 3 and an upper seat 4 arranged from bottom to top.

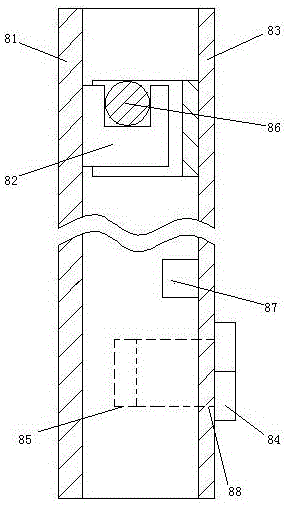

[0029] There are four supporting columns 9. The support column 9 includes a lower section 91 and an upper section 92 . The lower end of the lower section 91 is provided with a mounting base 911 . The upper end of the lower section 91 is slidably sleeved on the lower end of the upper section 92 . The lower section 81 is provided with a damping spring 93 supporting the upper section 92 . The upper end of the upper section 92 is provided with a connecting ring 921 . An inner ring 922 passes through the connecting ring 921 . The inner ring 922 is connected with the connecting ring 921 through the rubber ring 7 . The inner ring 922 is pierced with connecting pins 923 . The connecting pin 923 is connected with the lower end of the lowe...

Embodiment 2

[0042] Embodiment two, the difference with embodiment one is:

[0043] see Figure 9 , The supporting column 9 is also provided with a drive mechanism 6 . The inner ring 922 is rotatably connected to the rubber ring 7 , and the rubber ring 7 is fixedly connected with the connecting ring 921 .

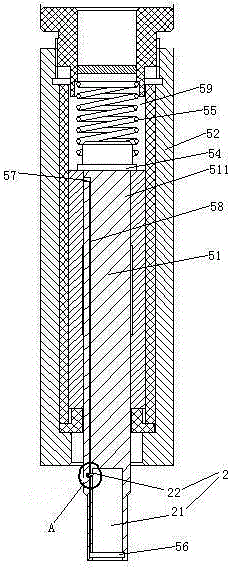

[0044] The drive mechanism 6 includes a ratchet 61 , a pawl 62 for driving the ratchet, and a drive lever 63 . The ratchet 61 is coaxially connected with the inner ring 922 . The ratchet 61 is integrated with the inner ring 922 . The pawl 62 is fixedly connected to one end of the driving rod 63 . The upper section 92 is provided with a sliding hole 924 . The other end of the driving rod 63 can slide through the sliding hole 924 two-dimensionally. The lower end of the drive rod 63 is slidably hooked to the lower section 91 along the radial direction of the connecting ring 921 (see figure 2 ) and connected with the next paragraph. The driving rod 63 is provided with a storage hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com