Stainless steel cold-rolled strip steel production device

A technology for cold-rolled strip steel and production equipment, which is applied in heat treatment equipment, metal processing equipment, workpiece surface treatment equipment, etc., can solve the problems of inability to roll and flatten welds, bottlenecks in production specifications of varieties, and small total deformation rate. Achieve the effect of strong applicability, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

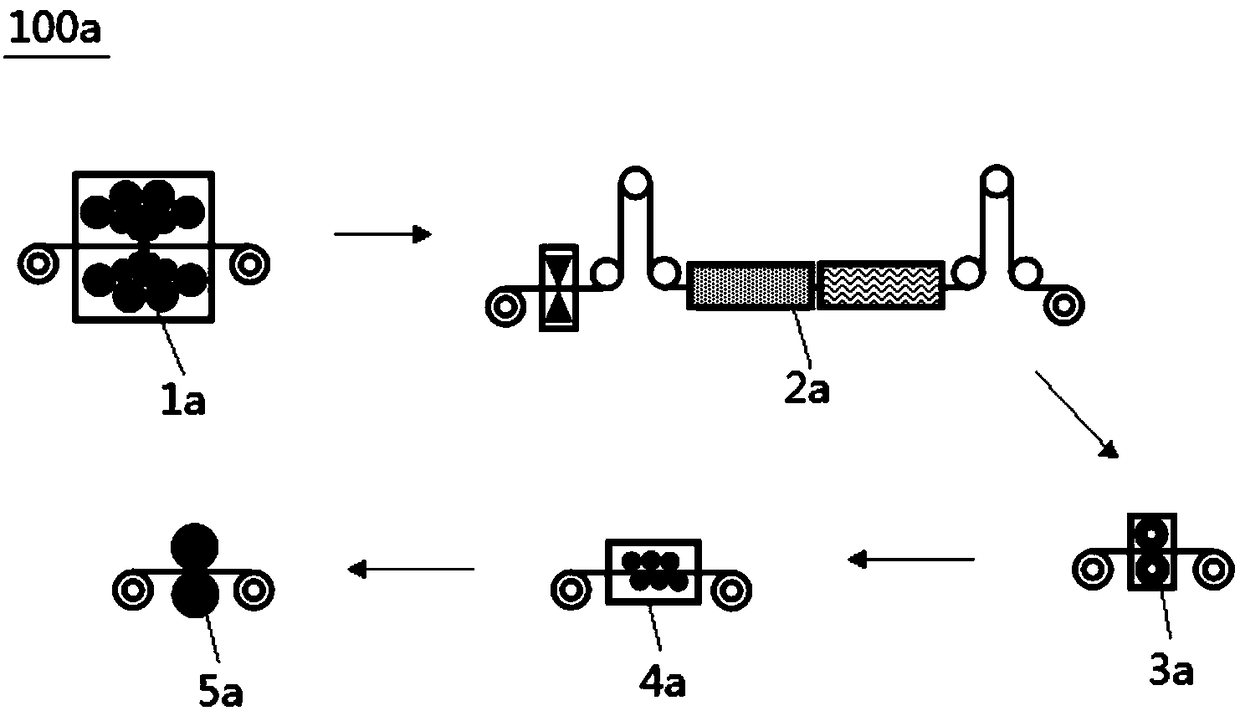

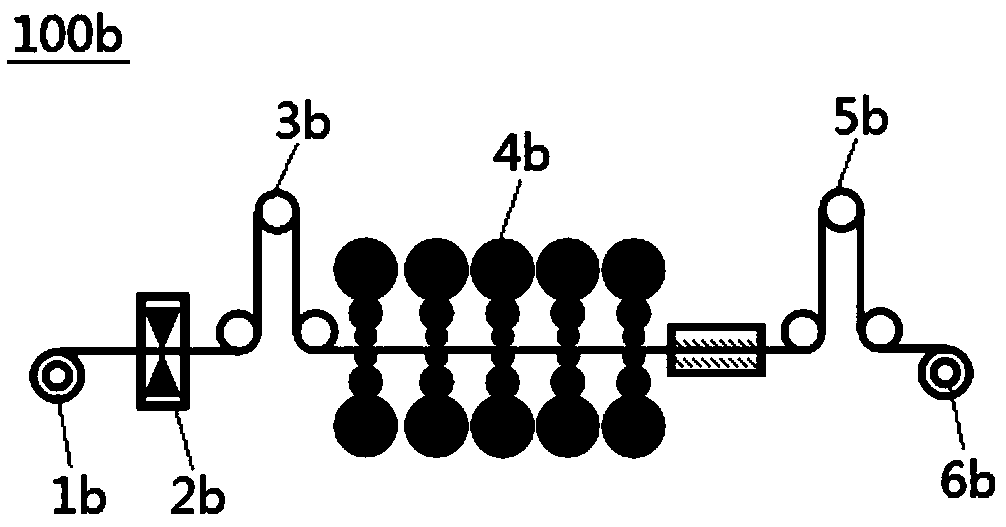

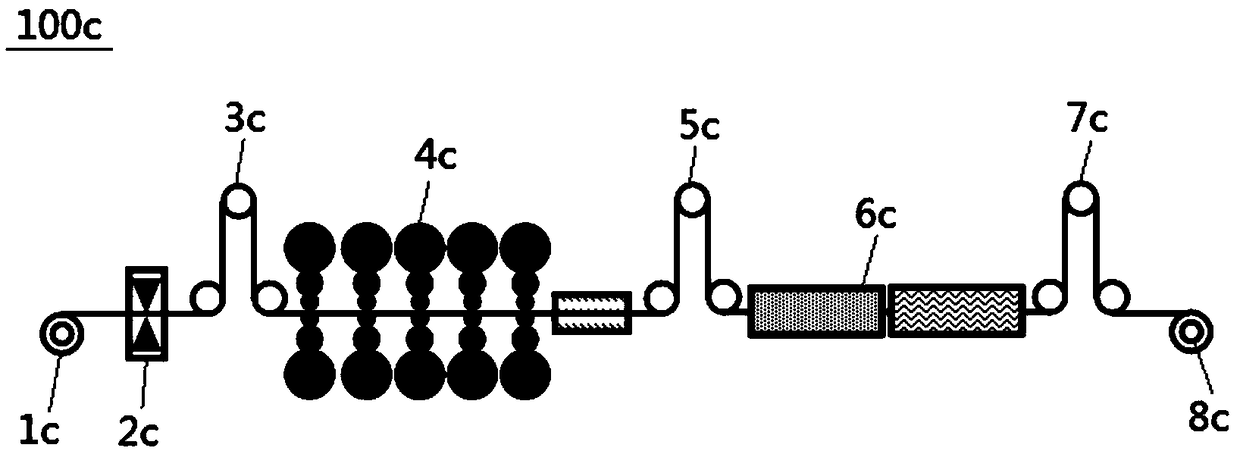

[0027] Figure 4 A schematic structural diagram of a stainless steel cold-rolled strip production equipment 100 according to the present invention is shown. Such as Figure 4 As shown, the stainless steel cold-rolled strip production equipment 100 includes successively connected raw material uncoiling and welding equipment 1, rolling equipment 2, annealing and pickling equipment 3, leveling and straightening equipment 4, edge finishing equipment 5 and finished product coiling equipment. Equipment 6, the raw material coils are uncoiled and loaded by the welding equipment 1 in turn to realize the welding of the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com