Method for manufacturing capacitive touch screen

A technology of a capacitive touch screen and a manufacturing method, which is applied in the direction of electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of increased thickness, volume cost, reduced anti-drop performance, low production efficiency, etc. The effect of good quality consistency, high yield and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

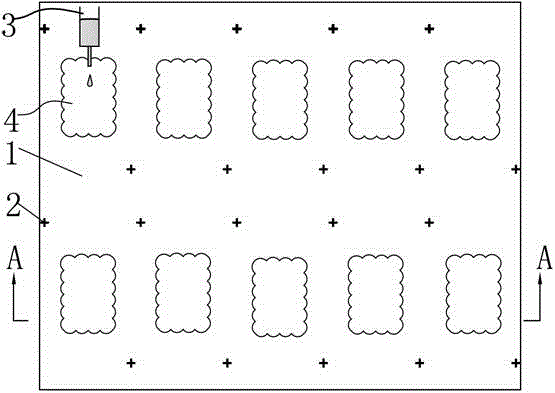

[0042] Below, the present invention will be further described by taking the capacitive touch screen of a mobile phone as an example in conjunction with the accompanying drawings:

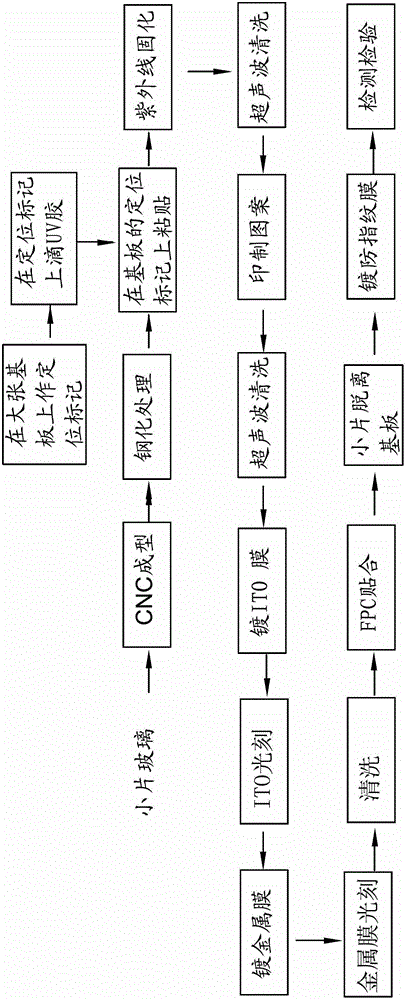

[0043] Referring to the accompanying drawings, the manufacturing method of the capacitive touch screen of the present invention includes process 1 and process 2.

[0044] Process one:

[0045] The large transparent substrate 1, as the carrier of the product glass 5, is made of 6-8mm thick flat glass or PC board, and its high strength and high transparency meet the requirements of the process of the present invention. Use the CCD positioning marking system to make array positioning marks on the large transparent substrate according to the designed product glass size. Since the designed product glass is rectangular, the positioning marks of each unit are marked at a right angle on a diagonal. can, if figure 2 Shown in mark 2.

[0046] Process two:

[0047] a. The small piece of glass that has bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com