Preparation method of high-quality self-support diamond thick film

A diamond thick film and diamond film technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of difficult diamond thick film, easy local cracks, and increased phase content, so as to avoid Partial or penetrating cracks, good quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

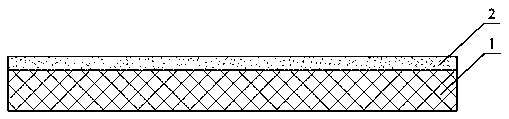

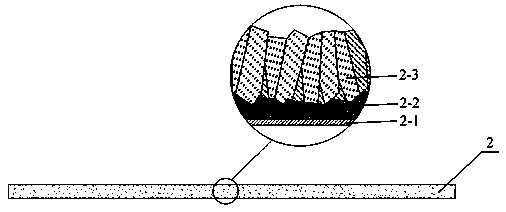

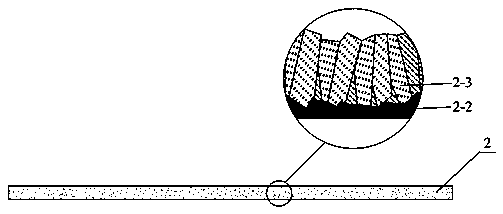

[0035] A high-quality diamond thick film with a diameter of 50 mm and a thickness of 2 mm was prepared using MPCVD equipment with a frequency of 2.45 GHz.

[0036] 1) Prepare a high-quality diamond film with a diameter of 50 mm and a thickness of 0.5 mm: use a Si disc with a thickness of 2 mm and a diameter of 50 mm as the substrate for preparing the diamond film, and grind the Si disc with diamond powder with a particle size of 0.2 μm to make it The surface is uniformly roughened to increase the diamond nucleation density, then ultrasonically cleaned in acetone solution, and dried with hot air. Open the reaction chamber of the MPCVD equipment, place the cleaned Si wafer at the center of the substrate table in the reaction chamber, close the reaction chamber and turn on the vacuum system, and wait until the vacuum degree of the chamber reaches 1×10 -2 When it is below Pa, feed hydrogen with a purity of 99.9999%, and its flow rate is 300 sccm, adjust the pressure of the reactio...

Embodiment 2

[0040] A high-quality diamond thick film with a diameter of 70 mm and a thickness of 3 mm was prepared using an MPCVD equipment with a frequency of 2.45 GHz.

[0041] 1) Preparation of a high-quality diamond film with a diameter of 70 mm and a thickness of 0.6 mm: use a Si disc with a thickness of 3 mm and a diameter of 70 mm as the substrate for preparing the diamond film, and grind the Si disc with diamond powder with a particle size of 0.2 μm to make it The surface is uniformly roughened to increase the diamond nucleation density, then ultrasonically cleaned in acetone solution, and dried with hot air. Open the reaction chamber of the MPCVD equipment, place the cleaned Si wafer at the center of the substrate table in the reaction chamber, close the reaction chamber and turn on the vacuum system, and wait until the vacuum degree of the chamber reaches 1×10 -2 When it is below Pa, feed hydrogen with a purity of 99.999%, and its flow rate is 700 sccm, adjust the pressure of th...

Embodiment 3

[0045] A high-quality diamond thick film with a diameter of 150 mm and a thickness of 3.5 mm was prepared using MPCVD equipment with a frequency of 915 MHz.

[0046] 1) Preparation of a high-quality diamond film with a diameter of 150 mm and a thickness of 0.7 mm: use a Si disc with a thickness of 5 mm and a diameter of 150 mm as the substrate for preparing the diamond film, and grind the Si disc with diamond powder with a particle size of 0.5 μm to make it The surface is uniformly roughened to increase the diamond nucleation density, then ultrasonically cleaned in acetone solution, and dried with hot air. Open the reaction chamber of the MPCVD equipment, place the cleaned Si wafer at the center of the substrate table in the reaction chamber, close the reaction chamber and turn on the vacuum system, and wait until the vacuum degree of the chamber reaches 1×10 -2 When it is below Pa, feed hydrogen gas with a purity of 99.99999%, and its flow rate is 2000 sccm, adjust the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com