Fish cooking device and control method

A technology of cooking device and control method, applied in heating device, steam cooking utensils, irradiation, etc., can solve the problems of low fish processing efficiency and low processing precision, and achieve good quality consistency, high processing precision and high processing efficiency. The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

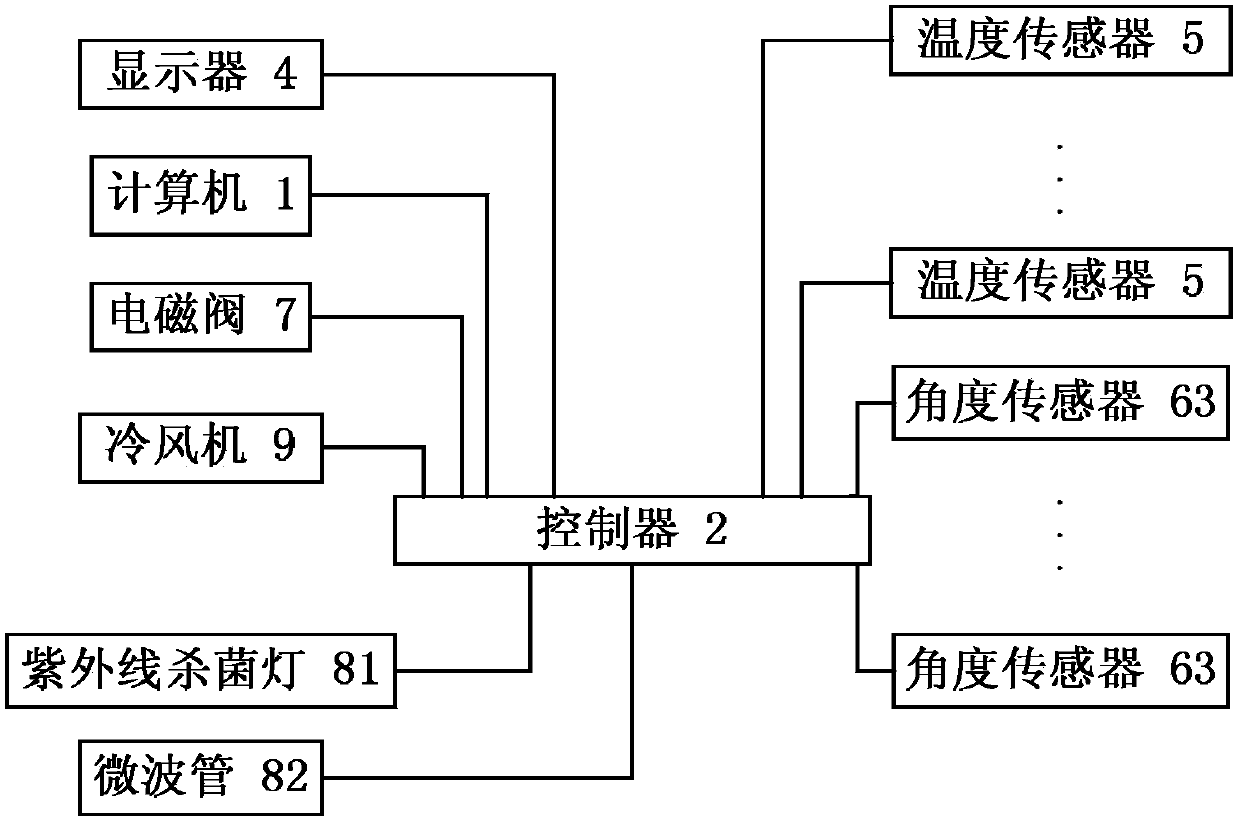

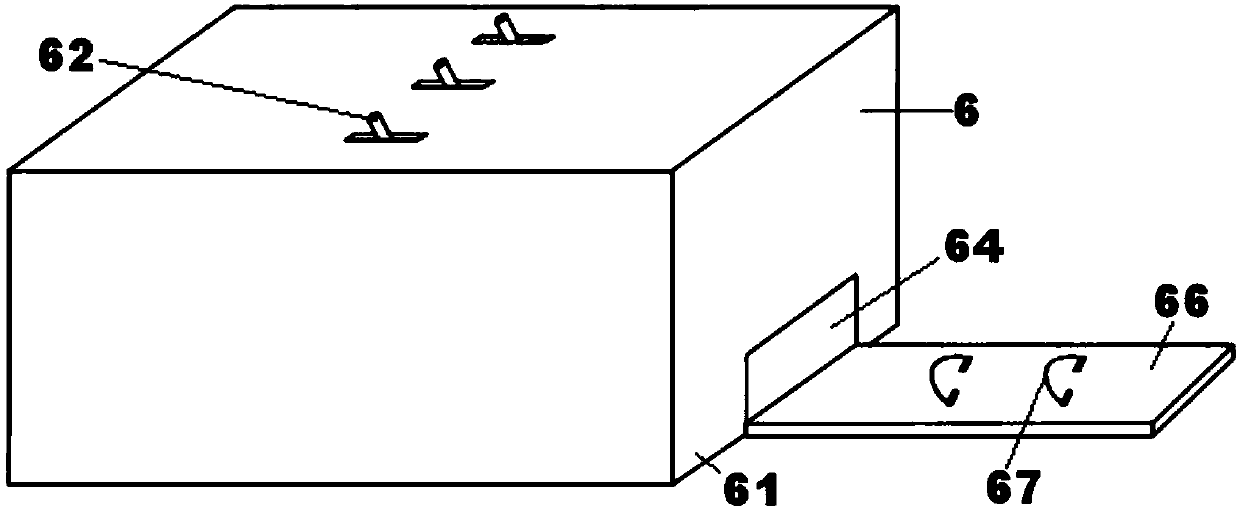

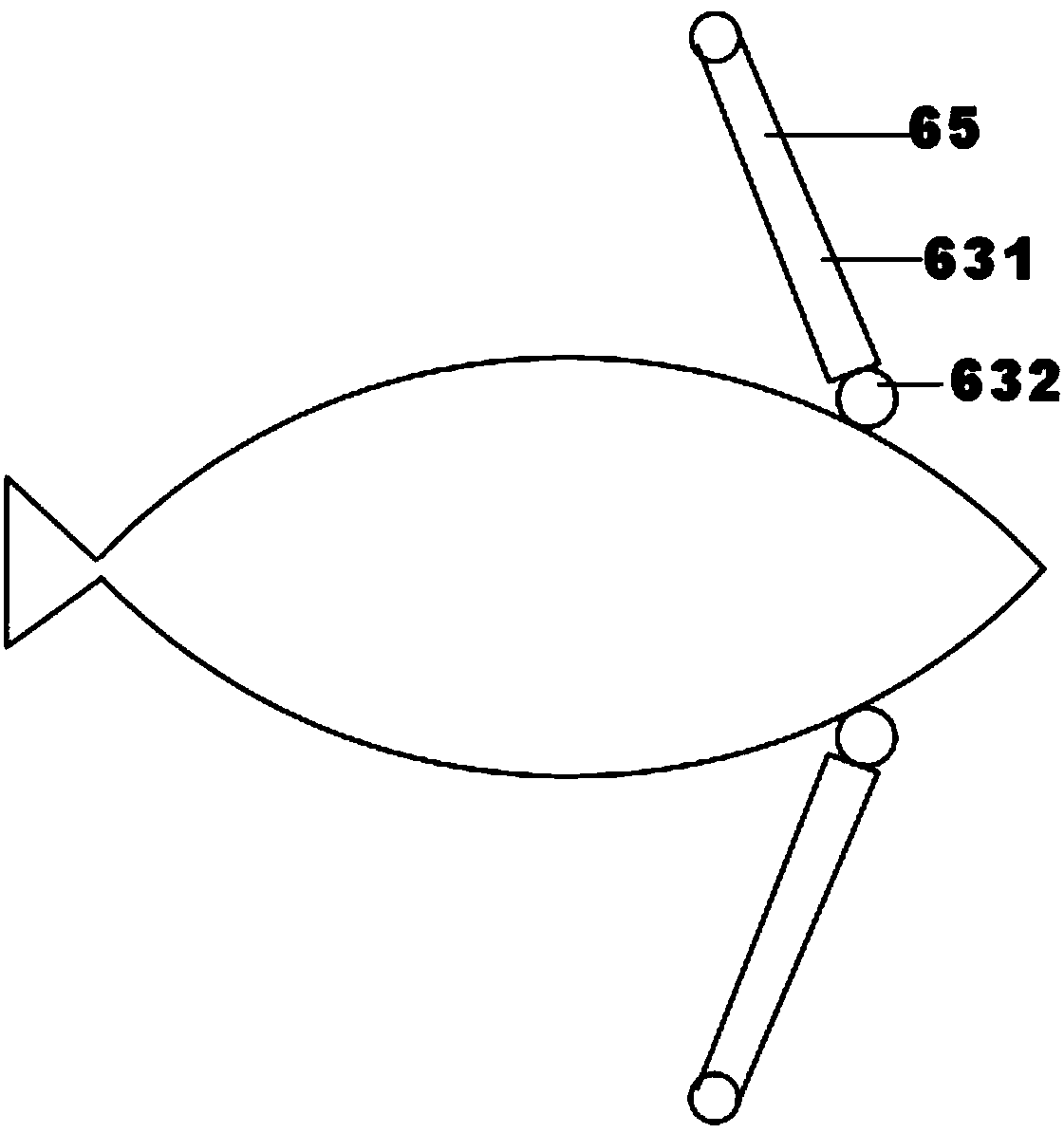

[0041] Such as figure 2 The illustrated embodiment is a fish cooking device, comprising a computer 1, a controller 2, a steamer, a display 4 arranged on the steamer, a steam inlet pipe arranged on the steamer and 5 temperature sensors 5, the dimensions The detection mechanism 6; the size detection mechanism includes a box body 61 with an open lower end, three first swing structures 62 that are rotatably connected to the cover plate of the box body, and five angle sensors 63 arranged on the cover plate; There is an opening 64, and the front and rear sides of the lower part of the box body are respectively provided with a second swing structure 65, and each angle sensor is connected with a corresponding first swing structure or a second swing structure, each first swing structure, each second swing structure Back-moving springs are arranged between the casing and the casing, and a solenoid valve 7 is arranged on the steam inlet pipe, such as figure 1 As shown, the controller i...

Embodiment 2

[0063] Embodiment 2 includes all structures and method parts of Embodiment 1, and Embodiment 2 also includes the following steps:

[0064] The temperature signal detected by each temperature sensor is processed as follows to obtain the detected temperature value:

[0065] The computer selects the current time period A1 and the previous time period B1 of each temperature sensor detection signal, and there are n1 detection values in each time period, A1 and B1 are 1 minute, and n1 is 60:

[0066] Set the detection value of time period A1 to x i , each detection value of time period B1 is y i , i=1,2,...,n;

[0067] use the formula Calculate the similarity of the detection values corresponding to the two time periods;

[0068] If s i i the corresponding y i delete; where, is the average value of all detected values in time period A1, is the average value of all detected values in the time period B1, and the computer calculates the remaining y in the time period...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com