Connecting machine for wardrobe connecting columns

A technology of connecting column and connecting machine, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor quality consistency, time-consuming and labor-intensive wardrobe connecting columns, etc., and achieve good quality consistency, convenient movement, and good connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

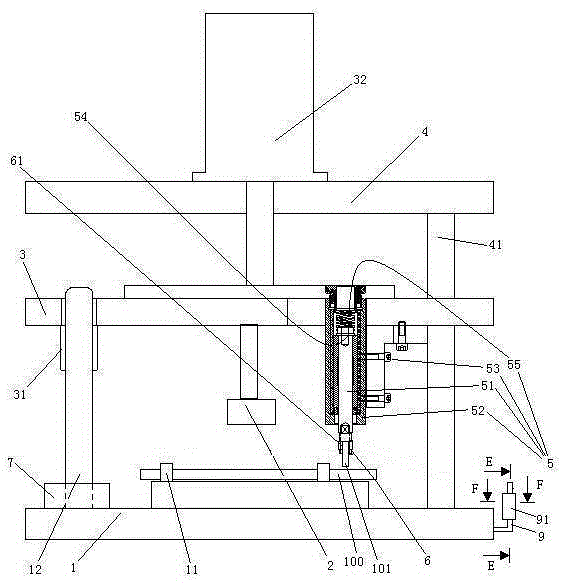

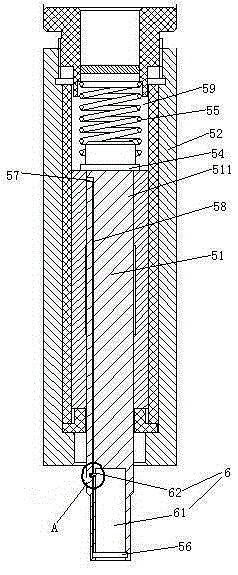

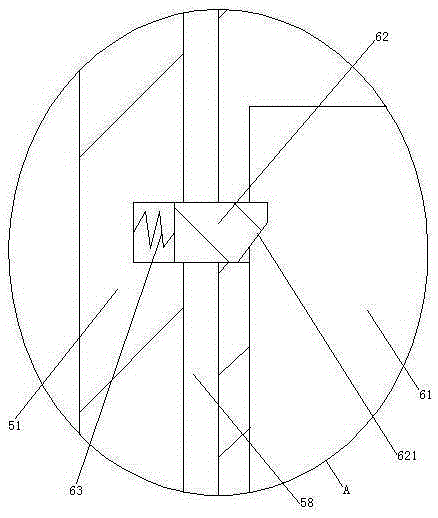

[0026] see figure 1 , a wardrobe connecting column connecting machine, comprising a base 1, a conductive block 2, a suspension plate 3 and an upper seat 4 arranged from bottom to top.

[0027] The base 1 is provided with a handle bar 9 . The outer elastic sleeve of the handle bar 9 is provided with a sleeve 91 .

[0028] The base 1 is provided with clips 11 and guide rods 12 . There are two clips 11. The guide bar 12 is provided with a rubber pad 7 . The rubber pad 7 is positioned under the suspension plate 3 . The conductive block 2 is fixed below the suspension plate 3 . Conductive block 2 is electrically connected together with the positive pole of electric welding machine (not shown in the figure). The suspension plate 3 is provided with a guide sleeve 31 . The guide sleeve 31 is slidably sleeved on the guide rod 12 . Suspension plate 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com