Metal and composite material connecting method based on bionic structure

A composite material and connection method technology, applied in the direction of coating, etc., can solve problems such as failure to meet metal and composite material connection requirements, stress concentration, bonding failure, etc., to avoid long-term reliability problems, stability enhancement, and good connection intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

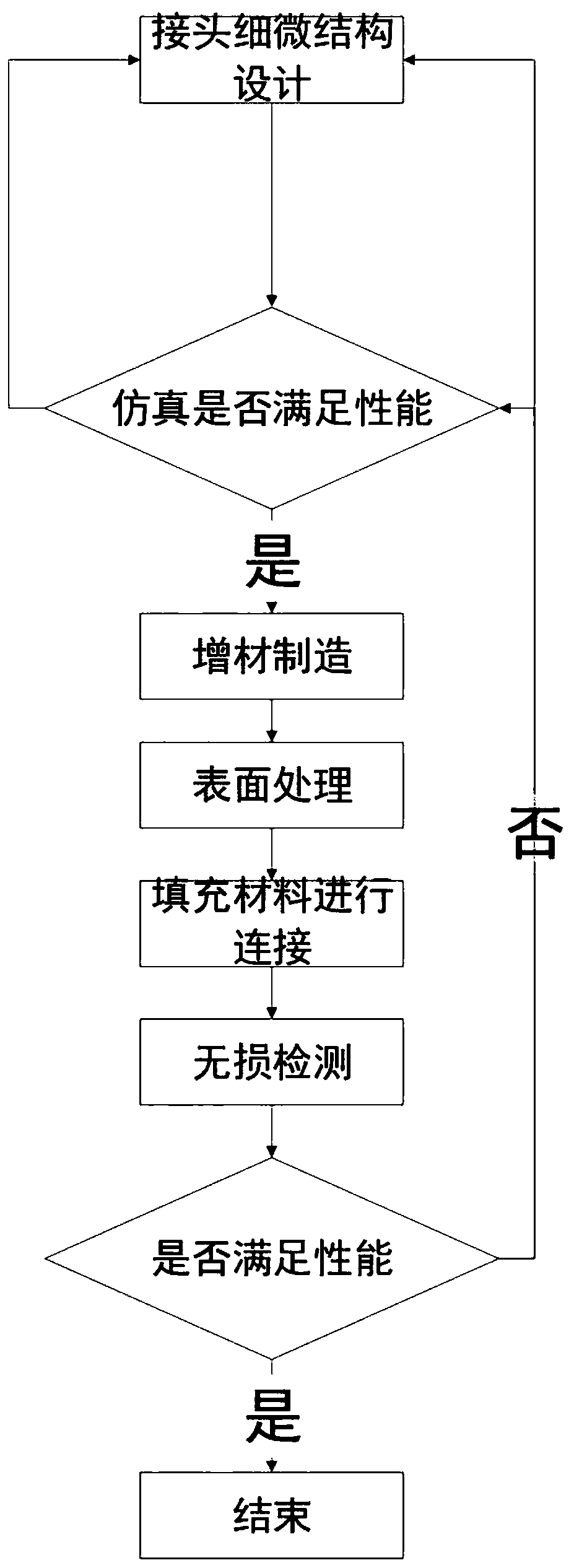

Method used

Image

Examples

Embodiment 1

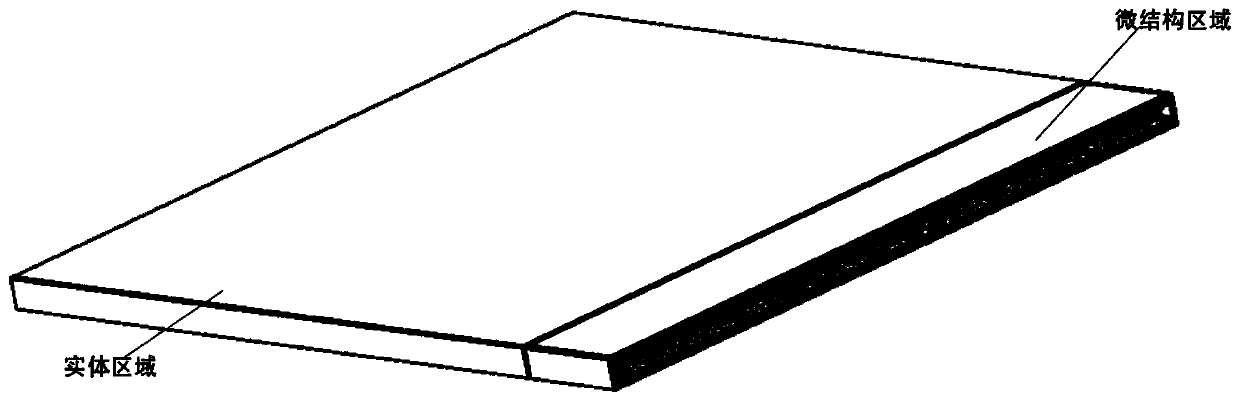

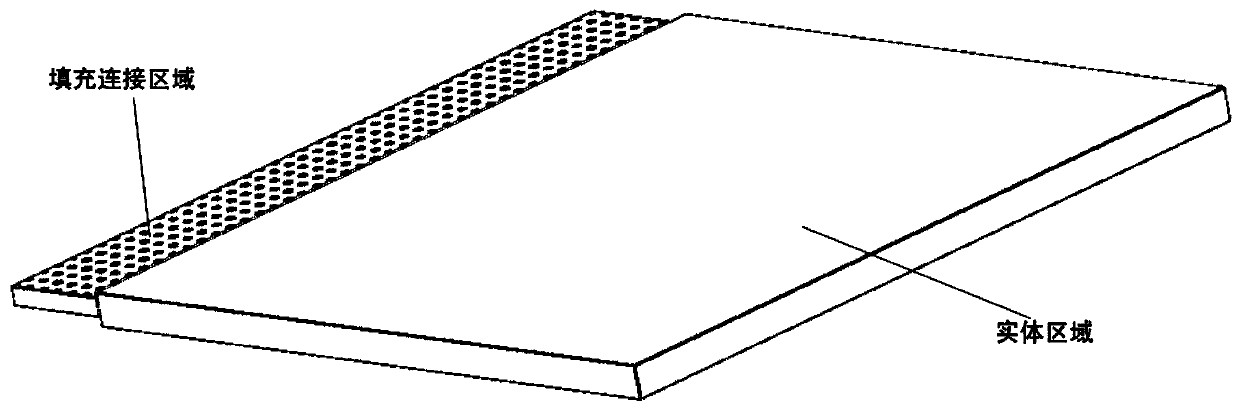

[0027] figure 2 The metal joint to be connected in this embodiment is manufactured by additive materials, including a solid area and a microstructure area, the solid area undertakes specific functions, and the microstructure area undertakes the connection function with the composite material; image 3 It is the connecting part of the composite material, including the solid area of the composite material and the filling connection area. The solid area undertakes specific functions, and the filling connection area and the filling connection area are figure 2 The microstructured regions in the

[0028] Figure 4 In this embodiment, after the metal joint and the composite material are connected as a whole, the metal region and the composite region are connected through a connection region with a microstructure, so that the metal region and the composite material region can realize their respective functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com