Flange used for heating tube of plastic inner container of water heater

A water heater liner and heating pipe technology, which is applied to flange connections, fluid heaters, lighting and heating equipment, etc., can solve the problems of easy water leakage or water seepage, easy safety hazards, inconvenient disassembly and assembly at the connection parts, etc. Wide range of use, compact structure and good connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

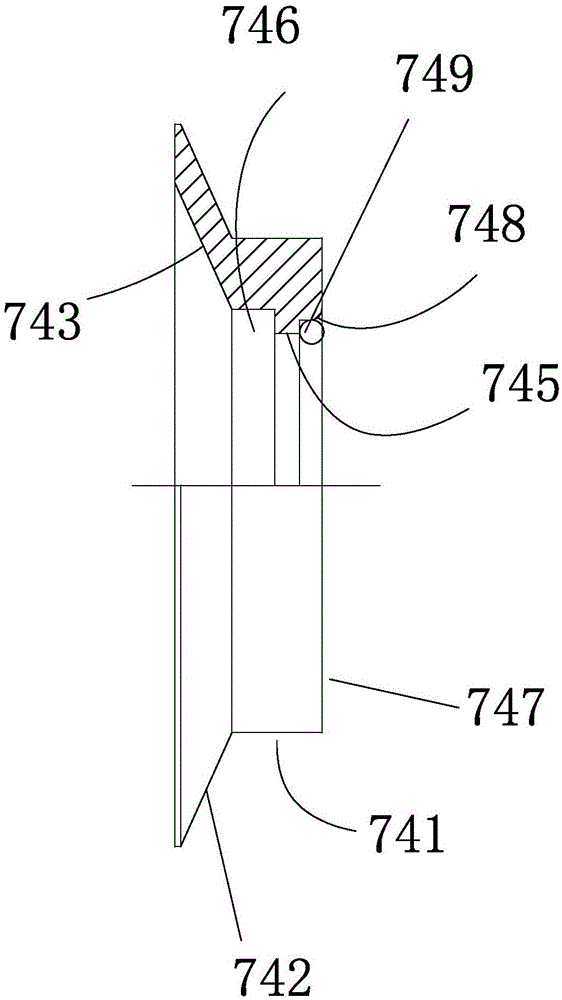

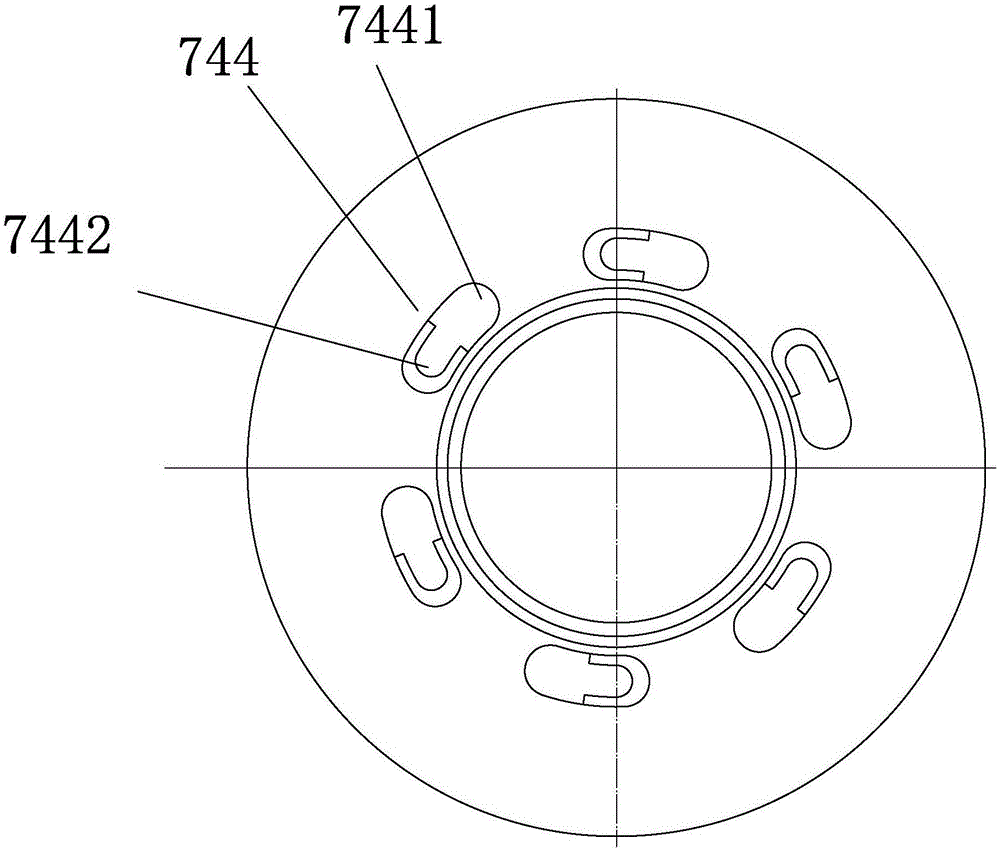

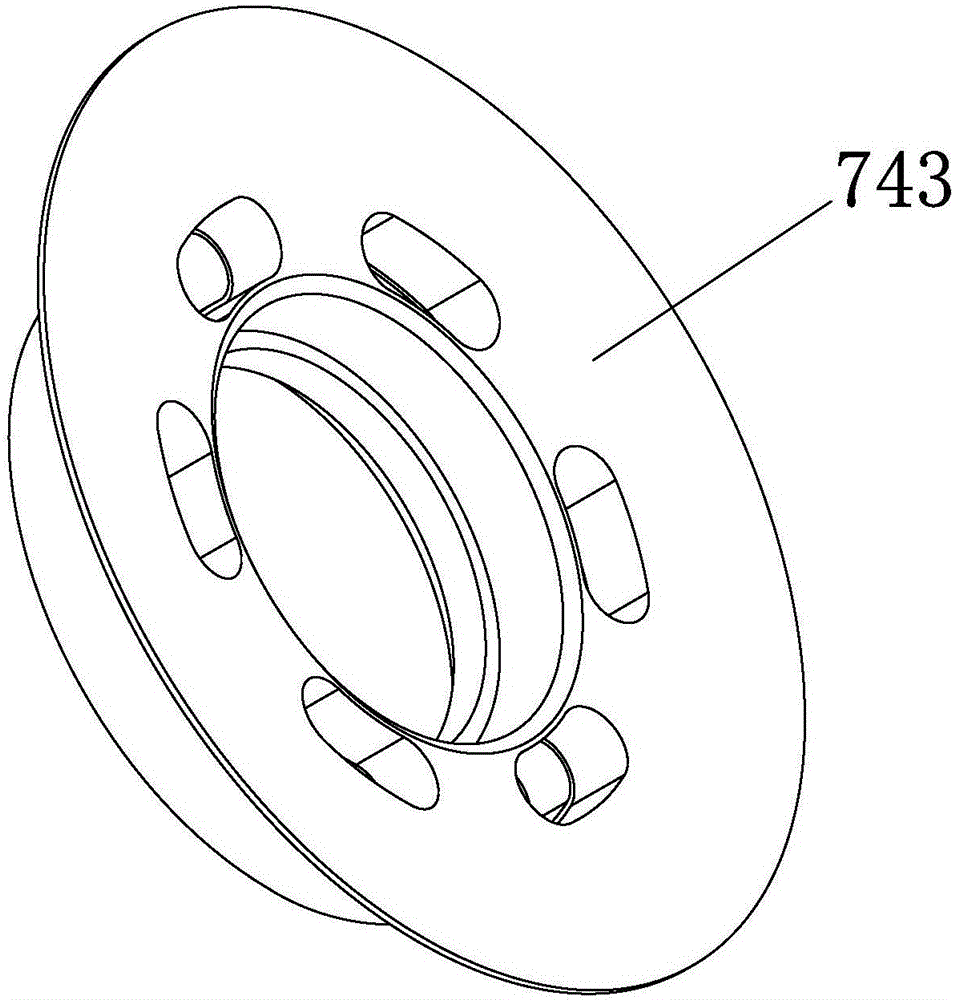

[0022] combine Figure 1 to Figure 3 , a water heater plastic liner heating pipe flange, comprising a connected cylindrical portion 741 and a conical portion 742, the cylindrical portion 741 is provided with a cylindrical hole, the cylindrical hole and the water heater liner spherical surface seal The outer circle of the cylindrical sleeve protruding outward from the head end fits, the inner surface 743 of the cone part 742 is in contact with the connecting surface of the water heater inner tank, and the outer end surface 747 of the cylinder part is provided with a flange near the edge The connecting hole 744, the flange is connected with the external heating structure through the flange connecting hole 744 and bolts.

[0023] The cylindrical inner hole is provided with excessive round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com