Processing method and processing equipment of light guide plate with protective film and light guide plate

A processing method and protective film technology, applied in the field of light guide plates, can solve the problems such as the difficulty of tearing off the protective film, and achieve the effect of improving efficiency and convenience, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be more clearly and completely described below by means of embodiments and in conjunction with the accompanying drawings.

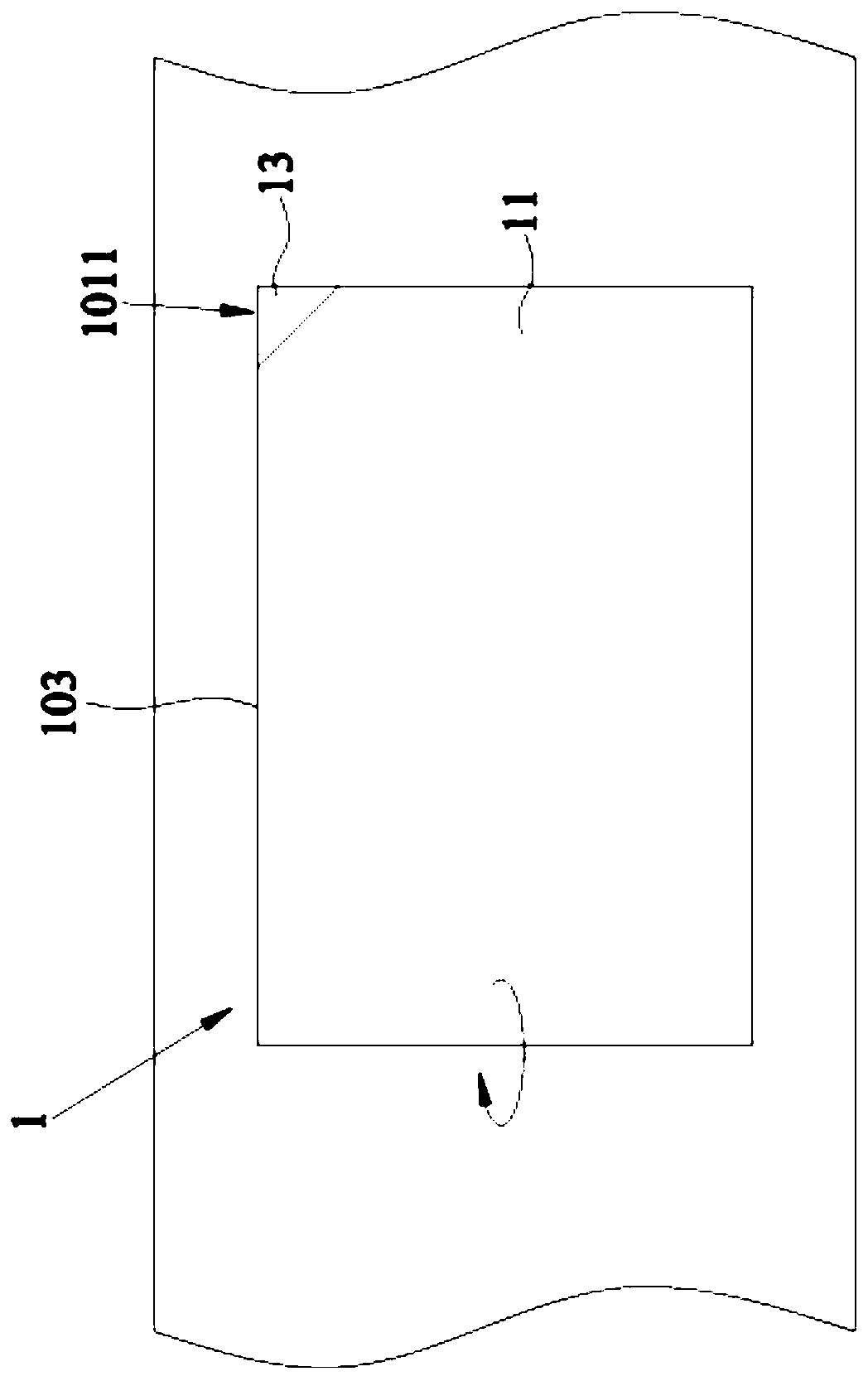

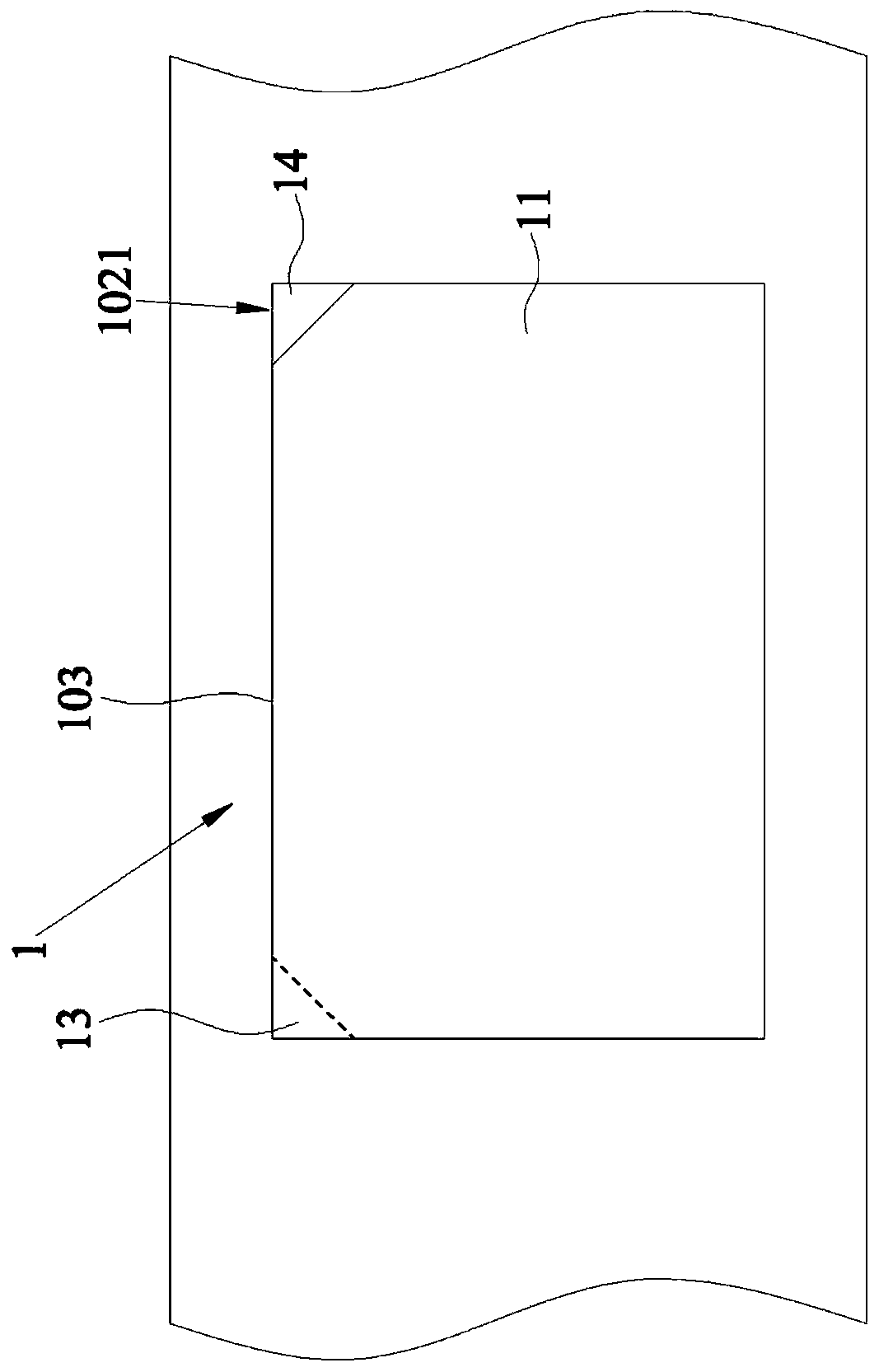

[0031] In order to improve the effect and convenience of removing the protective film of the current light guide plate, and thereby improve the efficiency and convenience of subsequent assembly applications, the inventor conceived and proposed a processing method, processing equipment and a processing method for a light guide plate with a protective film. The structure of the light guide plate formed after the method is described below for each technical feature one by one. Wherein, each drawing of the present invention is used to illustrate the technical features and means of the present invention, and does not represent the actual structural shape, thickness, size and other scale conditions.

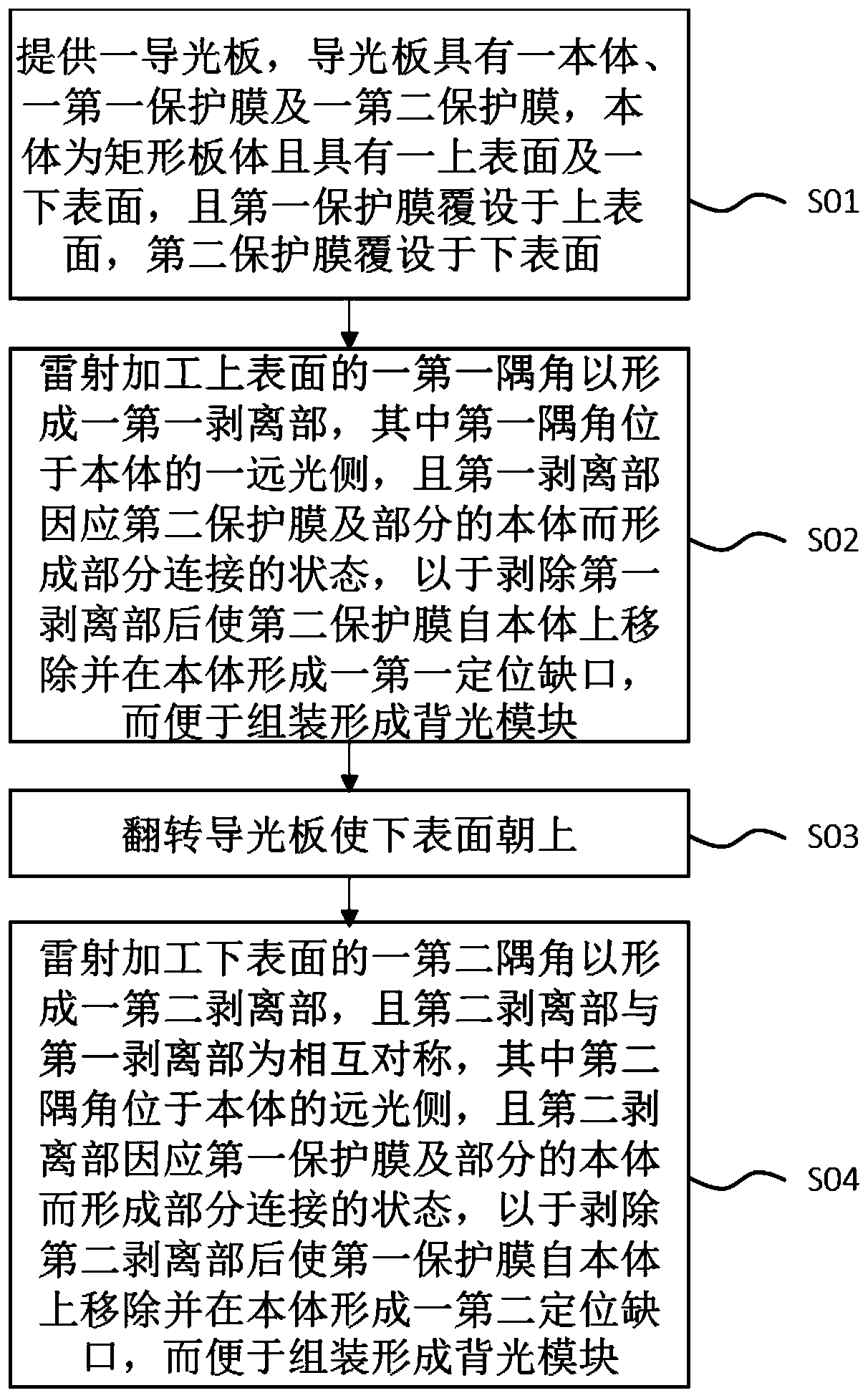

[0032] Please refer to figure 1 , which is the step diagram of the processing method of the present embodiment, and reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com