Binary isogram replacing constant-speed pneumatic conveying method

A technology of pneumatic conveying and pneumatic conveying system, which is applied in the field of value replacement and constant speed pneumatic conveying method, can solve problems such as the limited effect of system balance, and achieve the effect of clear principle, reliable and good stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

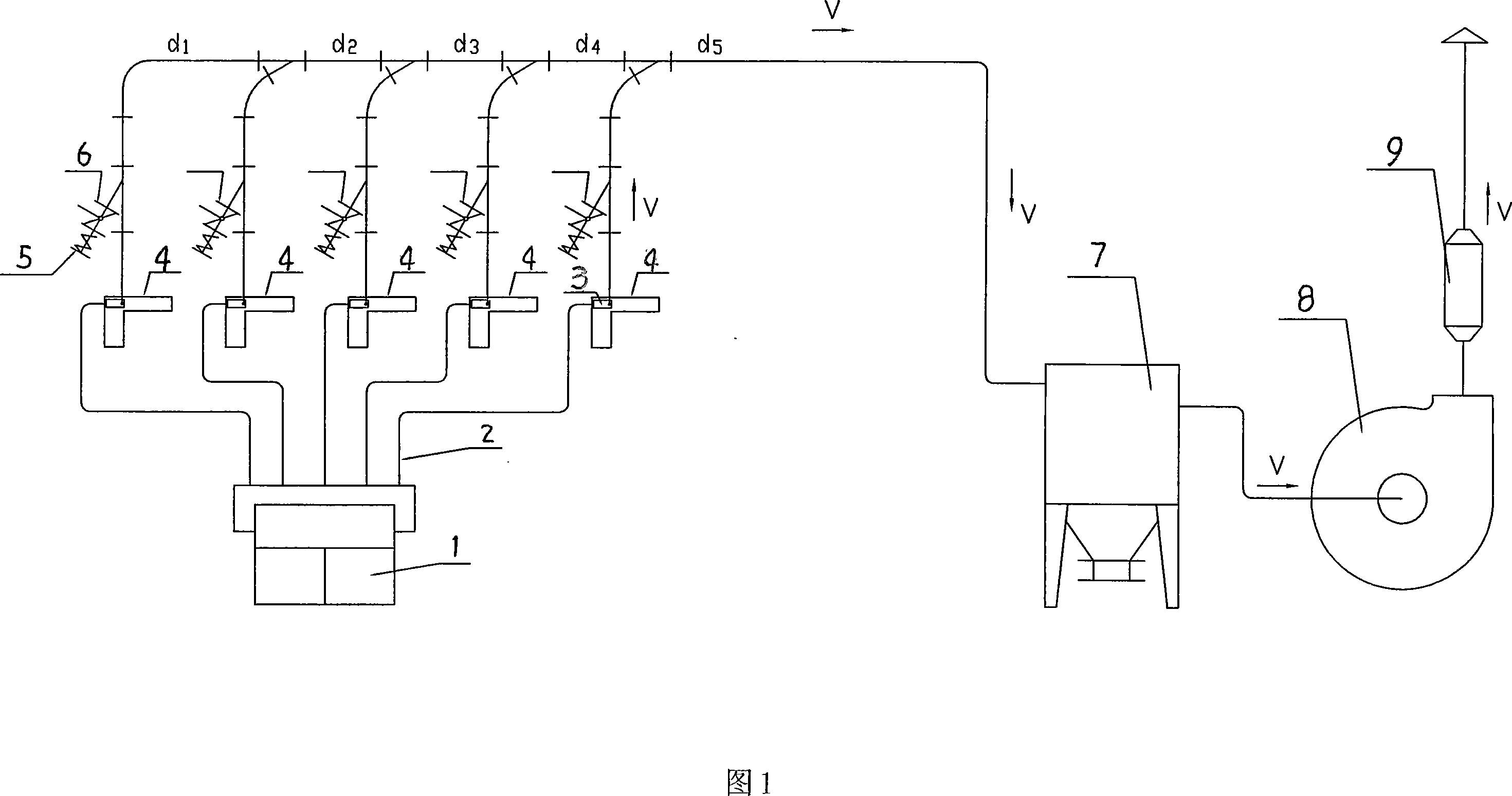

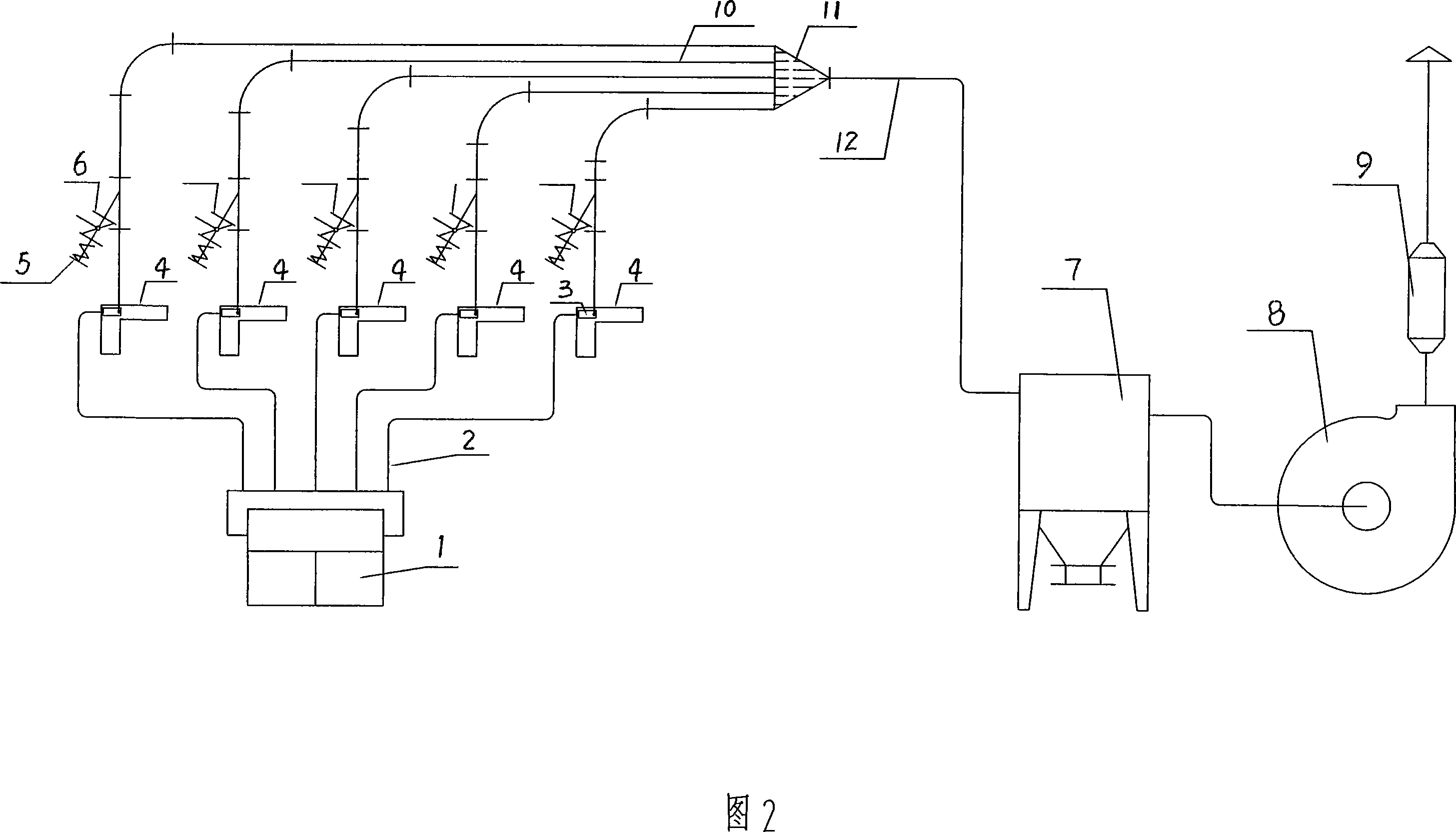

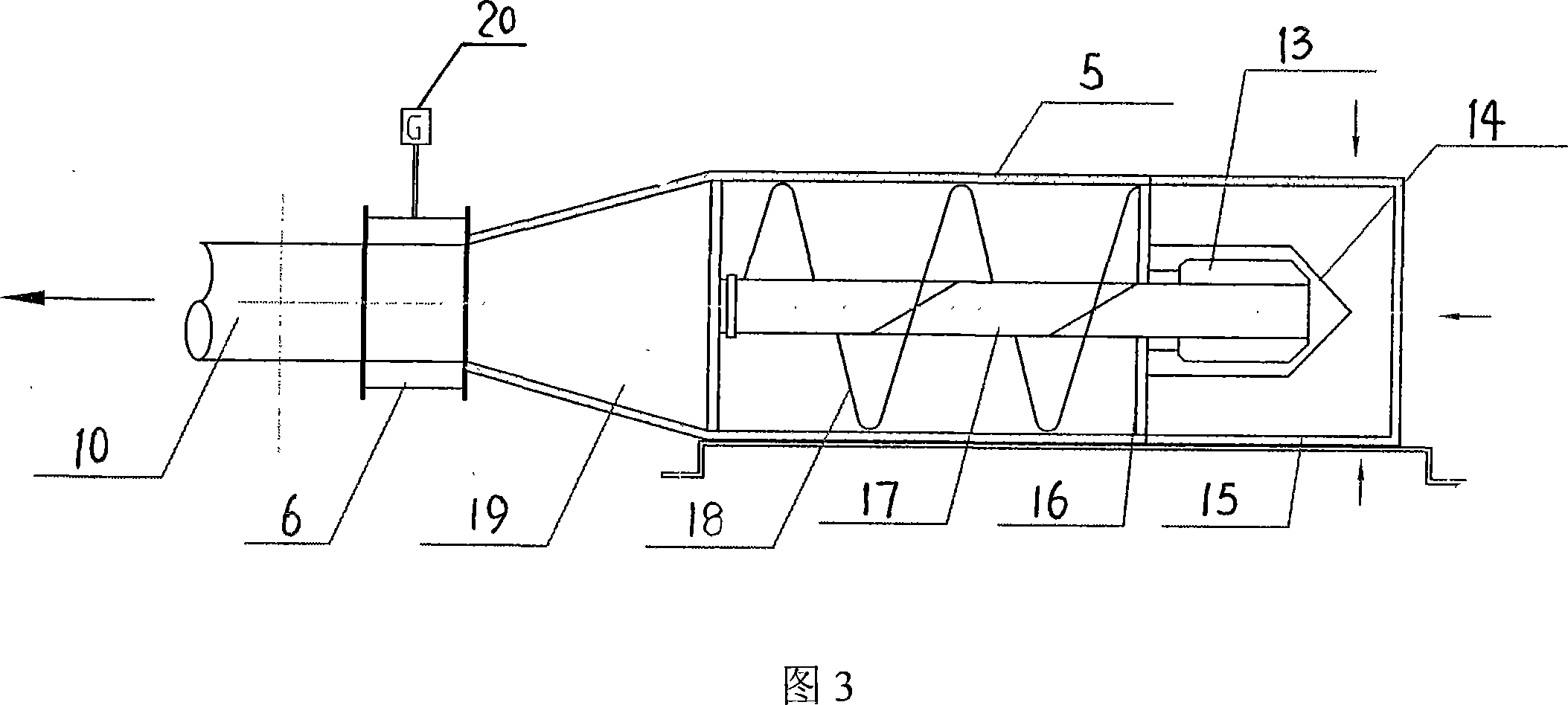

[0056] Take the wind-powered wire feeding system of the cigarette making machine as an example, as shown in Figures 1 and 2, the doffing hopper of the cigarette making machine 4 is divided into three upper and lower warehouses, and the lower warehouse continuously supplies shredded tobacco to the cigarette machine for high-speed rolling of finished cigarettes. When it falls to the control position of the set photoelectric material level gauge, the flap valve of the upper bin opens, and all the shredded tobacco in the bin falls into the lower bin, and then closes. Then the pneumatic valve 6 of the upper warehouse is opened, and under the action of the system negative pressure generated by the fan 8, the shredded tobacco is sucked into the doffing hopper of the cigarette unit from the remote wire feeder 1 through the wire feeding pipe 2 until the set level of the upper warehouse is reached. The pneumatic valve is then closed. A bypass pipe is provided at the inlet of the return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com