Inverter power compensation method based on droop control

A power compensation and inverter technology, applied in the direction of reducing/preventing power oscillation, current collectors, circuit monitoring/indicating, etc., can solve the problems of unfavorable load power grid scheduling, inapplicable energy storage battery supplementary power and energy storage, etc. Achieve the effect of preventing generator power overload from damaging equipment, suppressing violent fluctuations, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

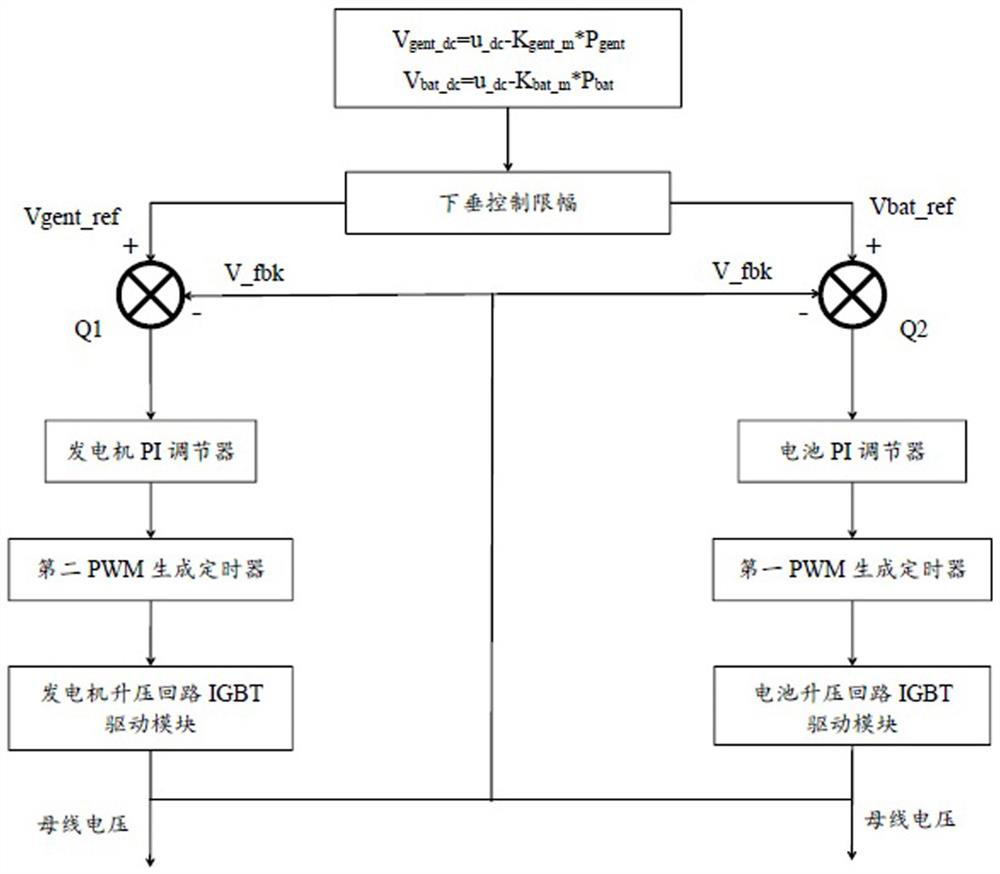

[0177] In a preferred embodiment, a 30KW inverter is selected for verification, the inverter having two distributed generation ports, an energy storage charging and discharging port, an inverter output port, the inverter output port is a three-phase four-wire port, a distributed generation port is a three-phase universal power port, can be connected to 100-500V co-frequency power supply, distributed power generation port two is a standby port, and distributed generation port one has the same structure and function.

[0178] The distributed generation port one is connected to a three-phase power frequency generator with adjustable output voltage, the energy storage charging and discharging port is connected to the energy storage battery with a rated voltage of 535V, the inverter output port is connected to a three-wire four-wire electronic load connection, and the real-time load power change is achieved by adjusting the electronic load, thereby verifying the inverter power compensa...

Embodiment 2

[0204] The operating conditions are similar to Example 1 and will not be repeated, the difference is that,

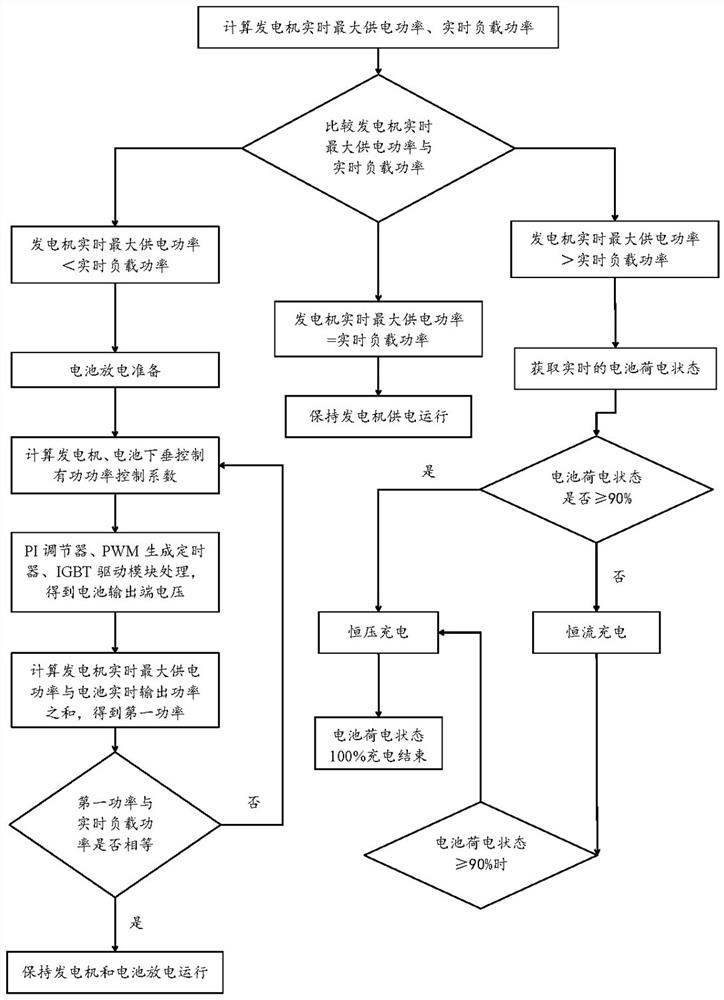

[0205] T 2 At the moment, the generator speed n = 3300r / min, as followed Figure 1 The flowchart shown includes the following steps:

[0206] S1: Calculate the generator real-time maximum power supply power, real-time load power;

[0207]According to Table 1, it can be seen that when the generator speed is 3300r / min, the conversion coefficient N between the rms value of the generator power and the rms value of the generator terminal voltage is 0.045, and the conversion coefficient Y between the rms value of the generator end voltage and the generator speed is 40, and the rms value of the generator end voltage is 150V after calculation, and the maximum power supply power of the generator in real time is P gent_max 6.00KW.

[0208] By the electronic load can be known, the real-time load power P load 2.7KW.

[0209] S2: The generator real-time maximum power supply power P gent_...

Embodiment 3

[0222] The same as Example 2 will not be repeated, the difference is that,

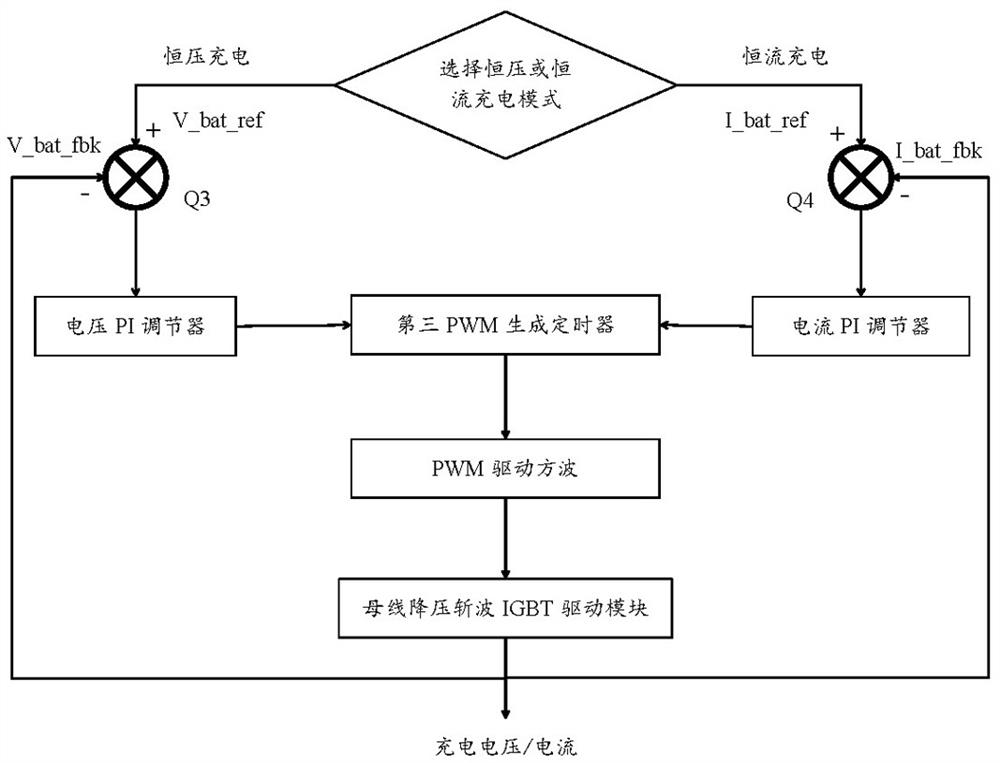

[0223] S21: The current real-time battery charge status (SOC) is obtained through the battery management system (BMS) of 91%, indicating that the remaining available power of the current battery accounts for 91% of the total capacity;

[0224]S22: In order to fully ensure the charging efficiency and charging safety, the present application to the battery nuclear power state 90% as the boundary, distinguish between constant current charging and constant voltage charging mode, since the current battery charge state > 90%, into the battery constant voltage charging mode, the battery for constant voltage charging, comprising the following steps:

[0225] S221: Obtain the battery allowable charging voltage corresponding to the battery state of charge, comprising the following steps:

[0226] S2211: The reference voltage of constant voltage charging corresponding to the current battery charge state is obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com