Method and device for improving quality of high-temperature alloy master alloy ingot by applying compound electromagnetic field

A technology for superalloy and master alloy ingots, which is applied in the field of preparation of superalloy master alloy ingots, can solve the problems of limited action range and effect, reduction of electromagnetic stirring time, deterioration of shrinkage cavity feeding conditions, etc., so as to eliminate adverse effects and achieve uniform Enhanced properties and purity, reduced effects of non-metallic inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

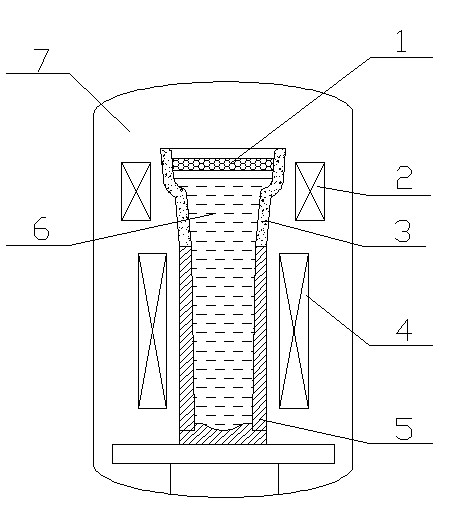

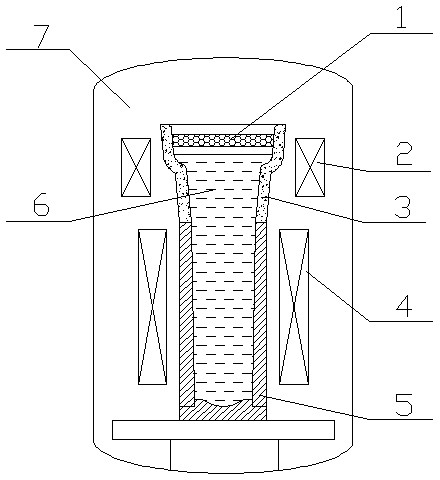

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] The device for applying a compound electromagnetic field to improve the quality of superalloy master alloy ingots of the present invention includes a vacuum intermediate frequency induction melting furnace 7, an austenitic stainless steel ingot mold 5 is arranged at the inner center of the vacuum intermediate frequency induction melting furnace 7, and the austenitic stainless steel ingot On the outside of the die 5, a DC electromagnetic field generator 2 with a magnetic induction intensity of 100-300 mT is arranged at a distance of 10-100 mm from its upper end face. A bidirectional low-frequency alternating current rotating electromagnetic field generator 4 with a frequency of 3-60 Hz and an input current of 60-200 A is arranged on the outside of the austenitic stainless steel ingot mold 5 at a distance of 20-250 mm from its lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com