Portable cutter wear measurement apparatus

A tool wear and measuring device technology, applied in measuring devices, optical devices, instruments, etc., to achieve the effect of simplifying optical testing equipment, shortening time consumption, and saving reinstallation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

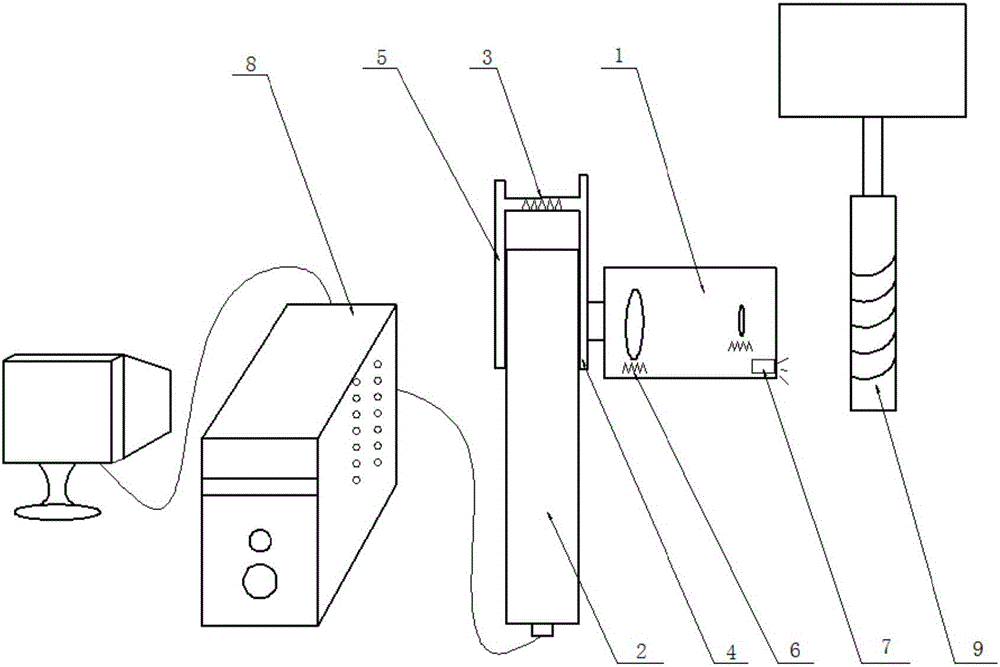

[0021] like figure 1 shown.

[0022] A portable tool wear measuring device, its holding feature is that it includes a microscopic microscope 1, a mobile phone 2 and an elastic mobile phone holder 3, the eyepiece end of the described microscopic microscope 1 is screwed on a jaw 4 of the elastic mobile phone holder 3, the The jaw 4 is provided with a through hole, which is opposite to the camera lens of the mobile phone 2. Another jaw 5 of the elastic mobile phone clamp is clamped on the front of the mobile phone 2. process, or send the captured image to a computer 8 pre-installed with image processing software through data lines or wirelessly for analysis to obtain tool wear data. like figure 1 shown.

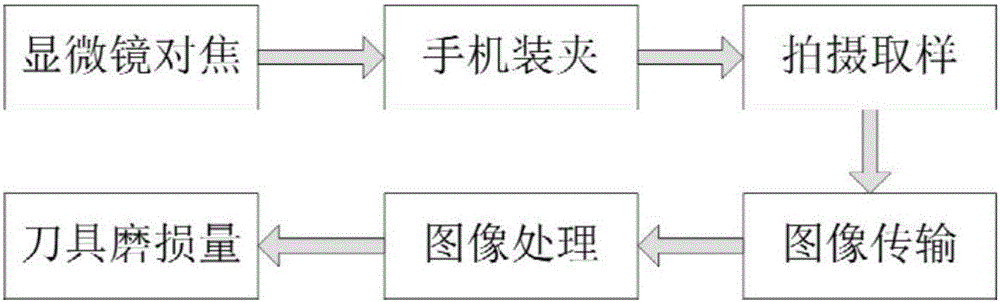

[0023] The using method of the present invention is as follows (see figure 2 ):

[0024] Step 1: Adjust the magnification knob of the micro-micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com