Machine special for link lever eight-station borehole

An eight-station, connecting rod technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of difficulty in ensuring consistent position and inability to adapt to mass production, so as to improve production efficiency and avoid repeated positioning errors , the effect of reducing the number of times of repeated installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

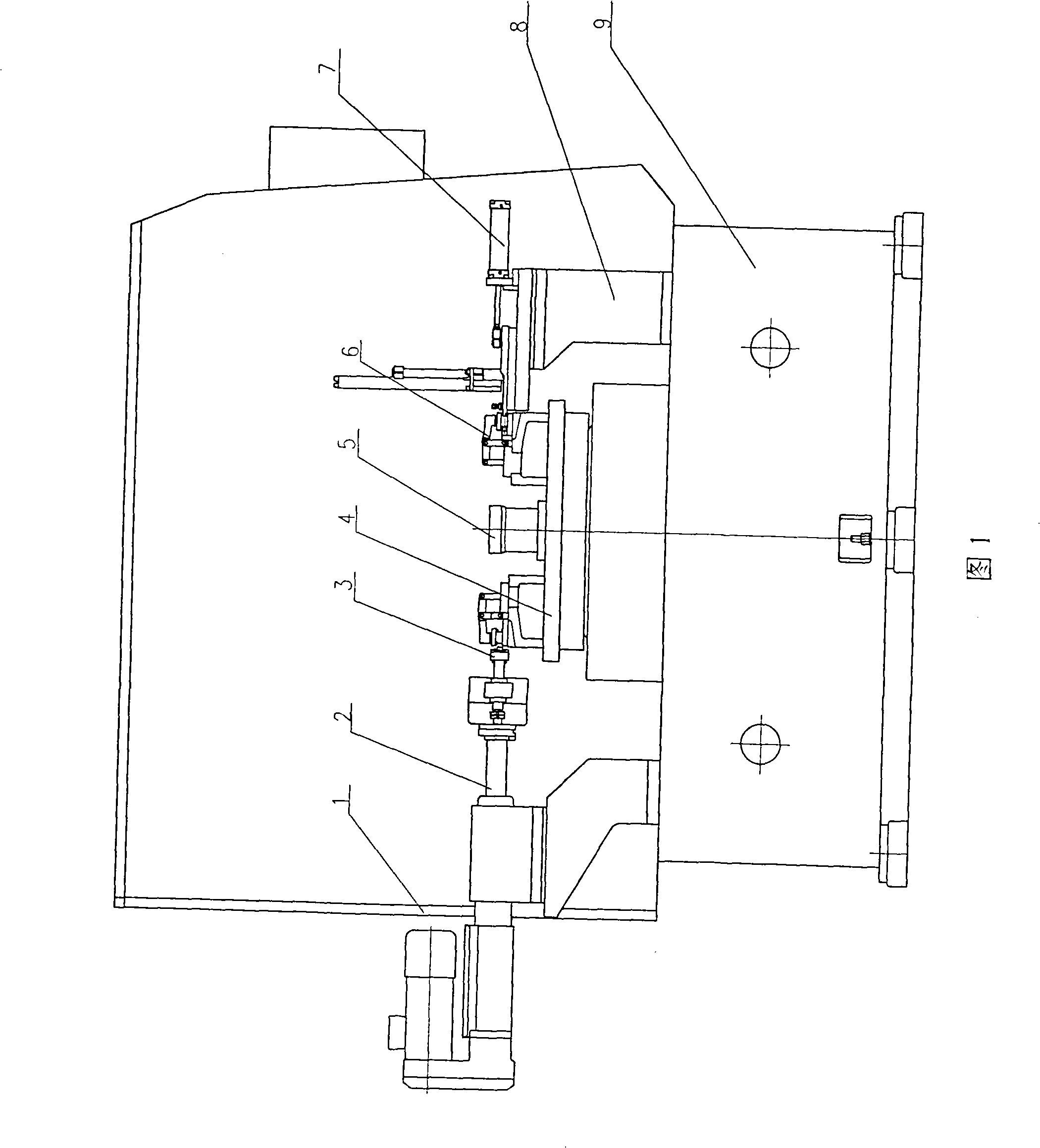

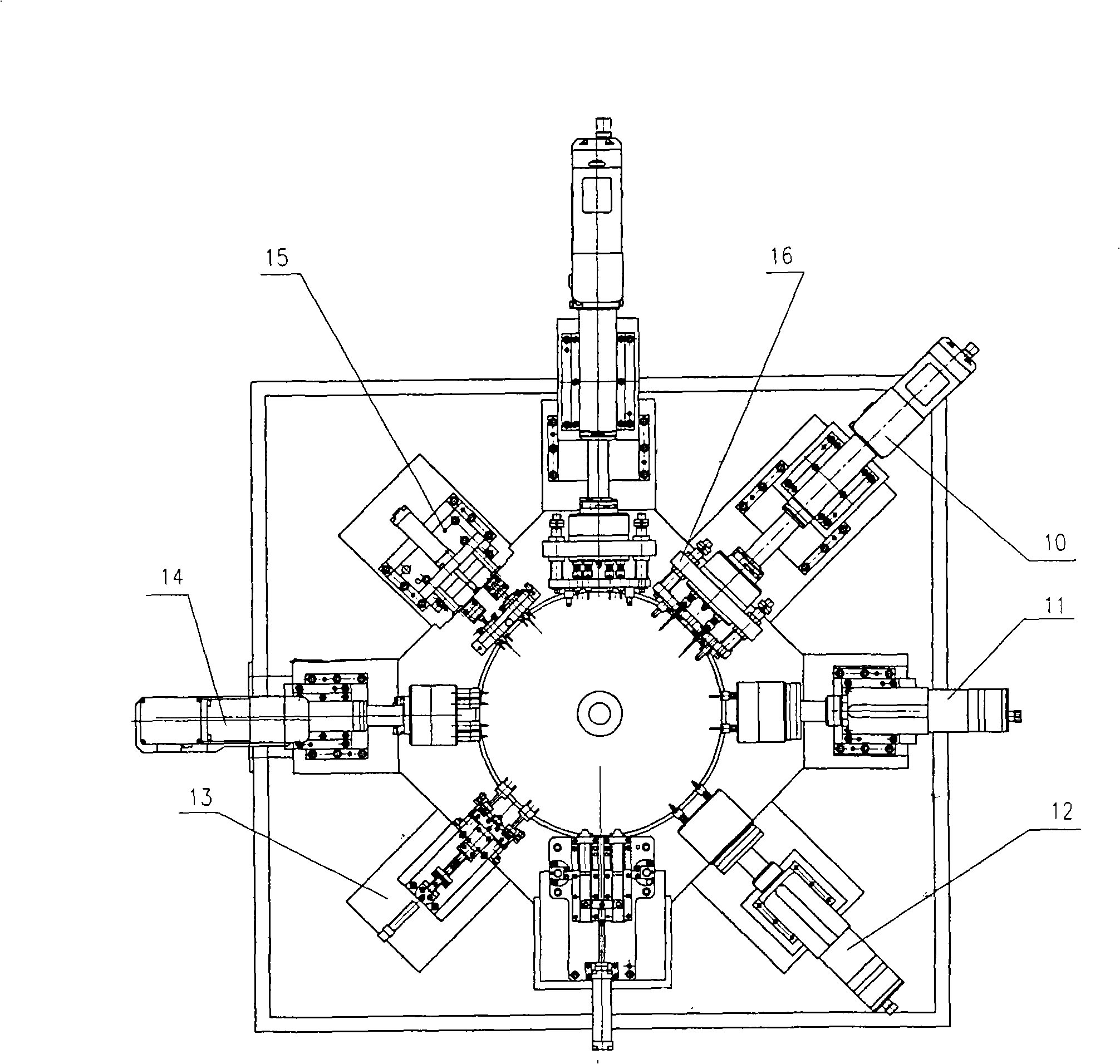

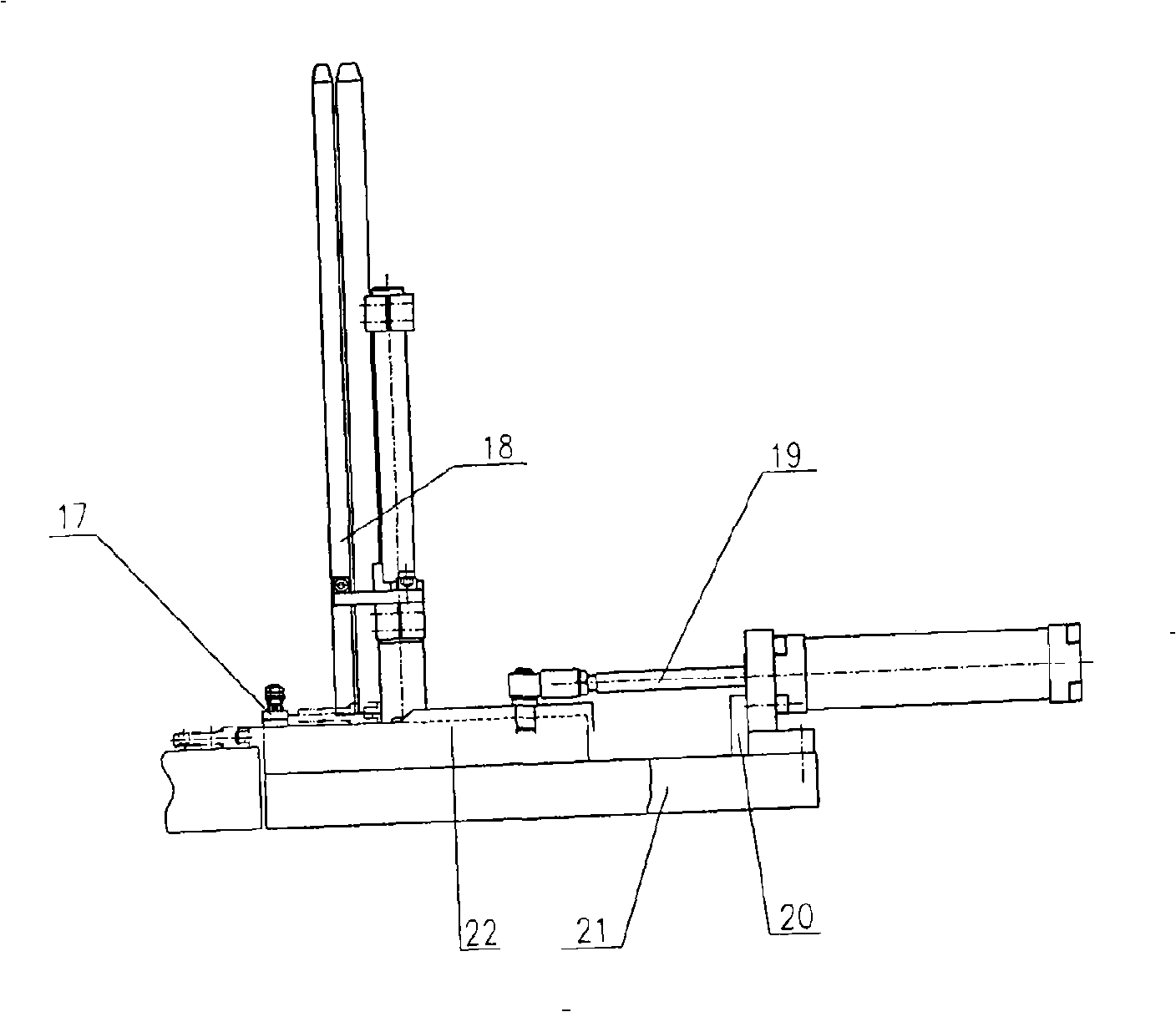

[0011] Compared with Figure 1, figure 2 , its structure is that the overall protection of the machine tool 1 is installed on the integral casting bed 9, the power head 2 connected with the threaded bottom hole of the four-axis drill is installed on the integral casting bed 9 through the power head seat 8, and the four-axis movable drilling template 3 is installed on the integral casting bed 9 through the guide rod It is connected with the four-axis power head 2. Due to the small diameter of the processed hole and the overhang of the drill bit, the movable drilling template 3 is added to ensure the position of the drilling hole. The rotary table 4 is fixed on the integral casting bed 9, and the fixture part 6 is fixed on the On the rotary table 4, the rotary table rotates once to complete the work of one station. The oil rotary distributor 5 is fixed at the center of the rotary table 4, the moving coil rotates with the rotary table 4, and the fixed ring is fixed and does not ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com