Vertical shaft tunnel concrete lining structure and method

A technology of concrete and concrete layer, which is applied in shaft lining, shaft equipment, earthwork drilling and mining, etc. It can solve the problems of long construction period, high construction cost, and high safety risk, so as to reduce labor cost, meet quality and efficiency, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

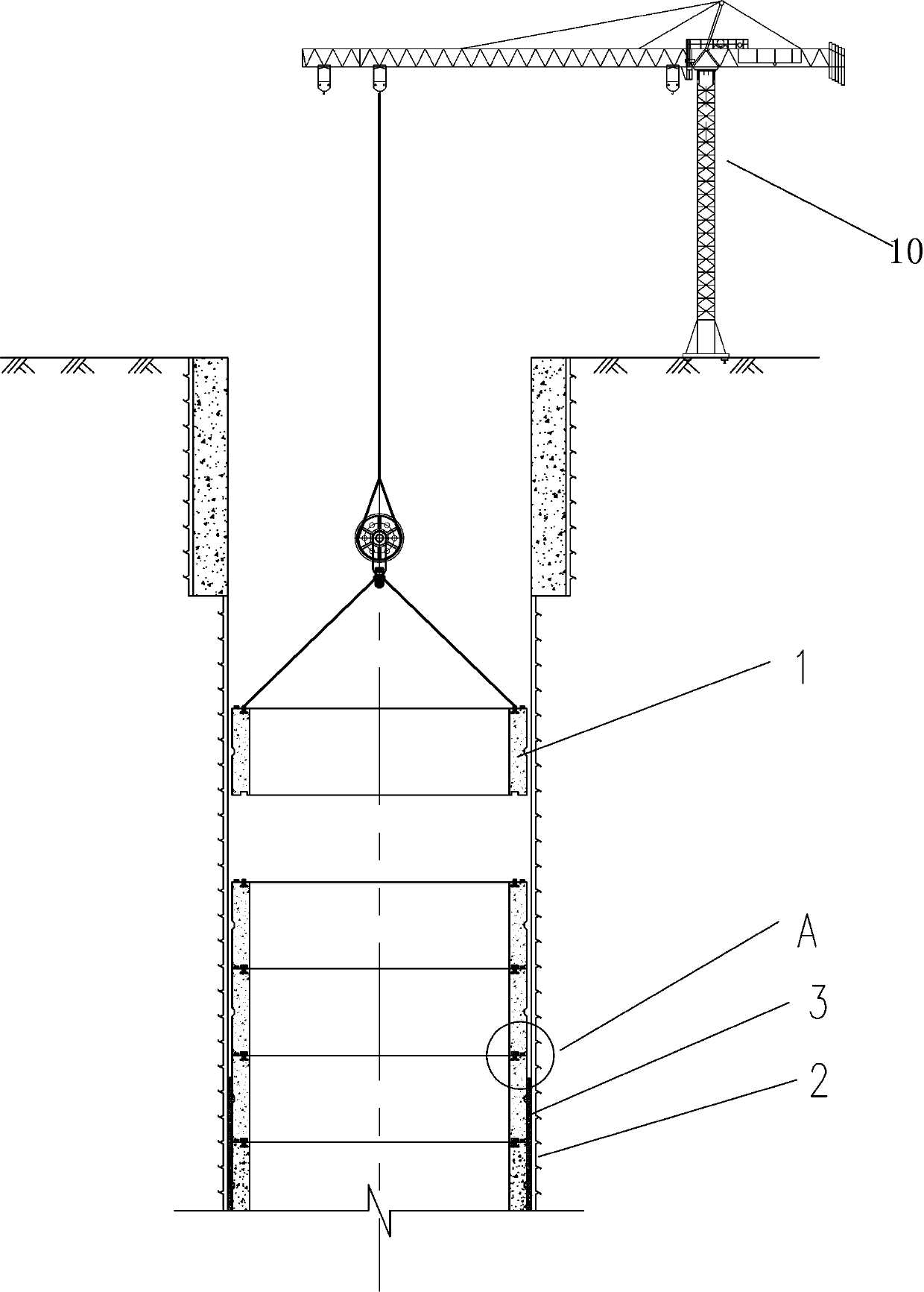

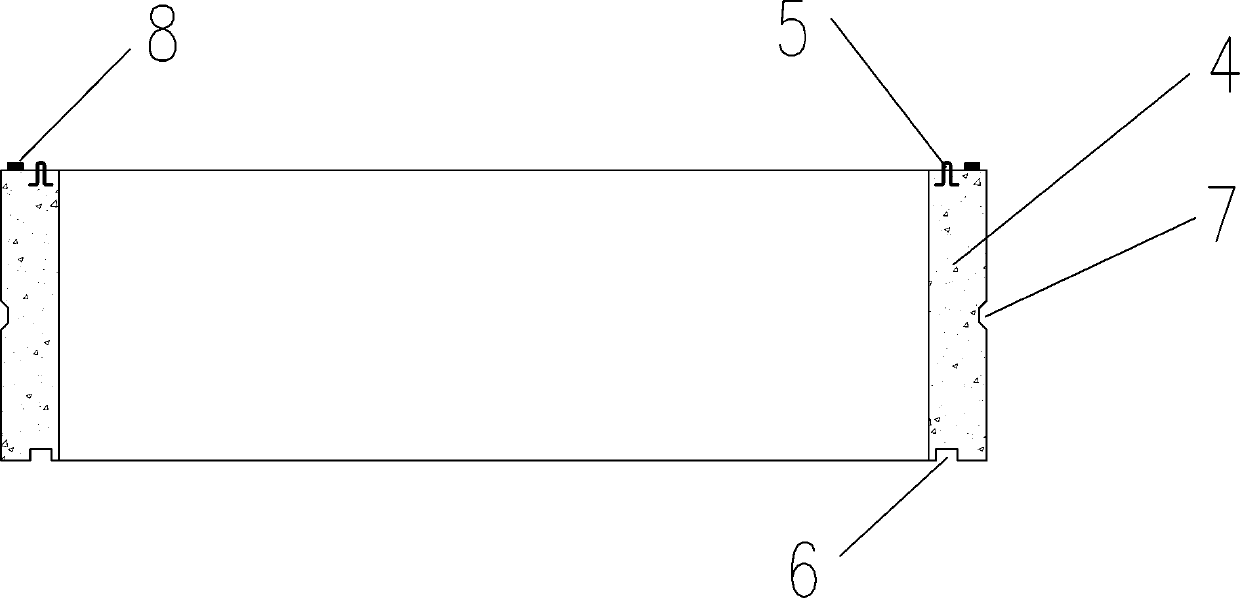

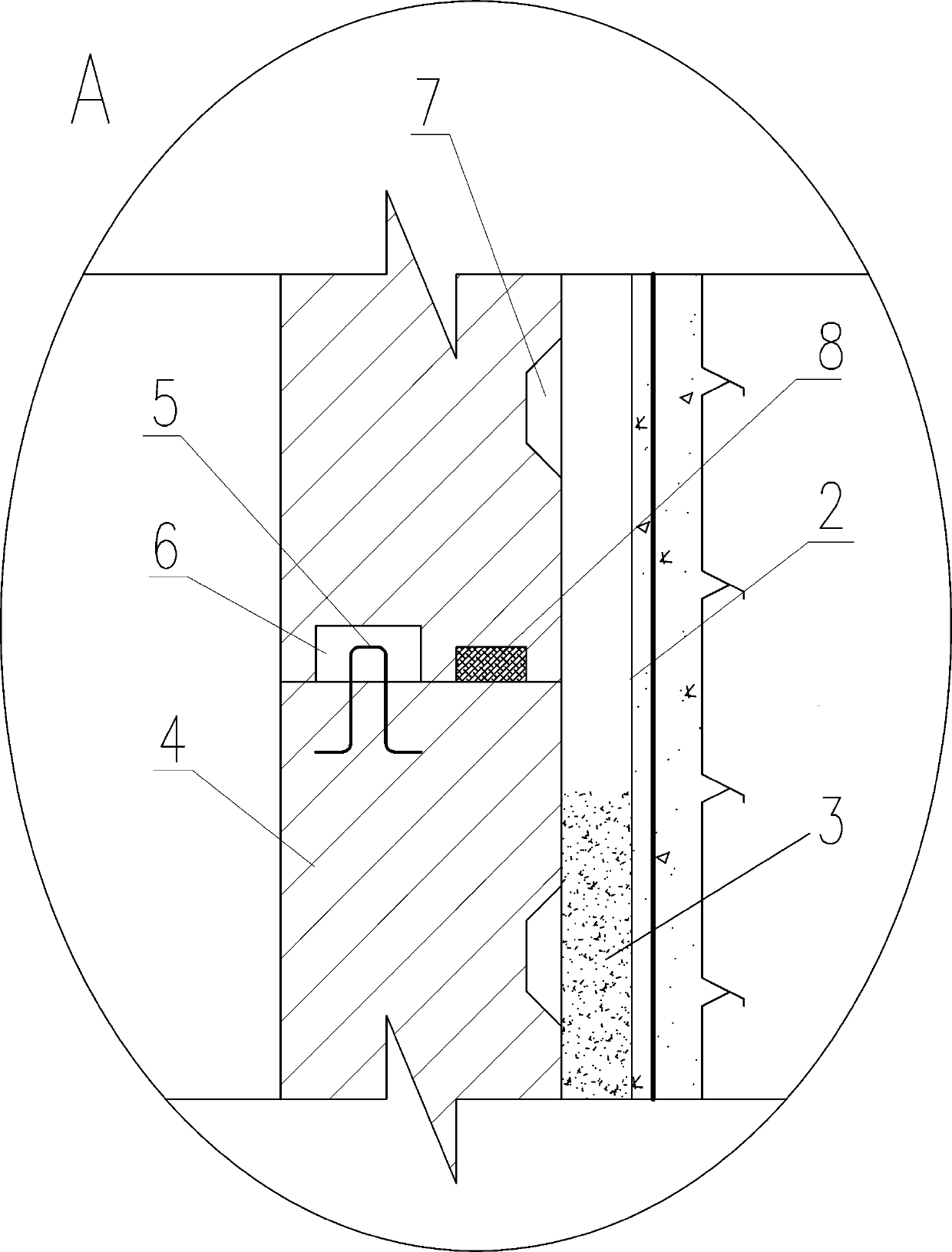

[0031] Such as Figure 1-4 As shown, a shaft tunnel concrete lining structure includes a prefabricated pipe joint 1, the prefabricated pipe joint 1 includes a prefabricated concrete pipe body 4, and the upper end of the prefabricated concrete pipe body 4 is provided with a lifting ring 5, which can be used to connect with a hoisting device 10 and lower it into the shaft , and the corresponding place at the lower end of the pipe body 4 is provided with an orifice 6 for the suspension ring to put in, so that a plurality of pipe bodies 4 can be assembled joint by joint to form a shaft lining structure. A 5cm gap is reserved between the outer wall of the prefabricated pipe and the surrounding rock surface 2 (specifically, the shotcrete surface of the surrounding rock). Connected into a whole to ensure the overall stability of the surrounding rock, and most of the self-weight load of the prefabricated pipe can be transmitted to the surrounding rock to ensure the structural safety d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com