Closed negative pressure solid waste oxygen control pyrolysis device

A solid waste, closed technology, applied in the field of energy saving and environmental protection, can solve problems such as low operating costs, and achieve the effects of reducing purification costs, meeting efficiency, and reducing the proportion of pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

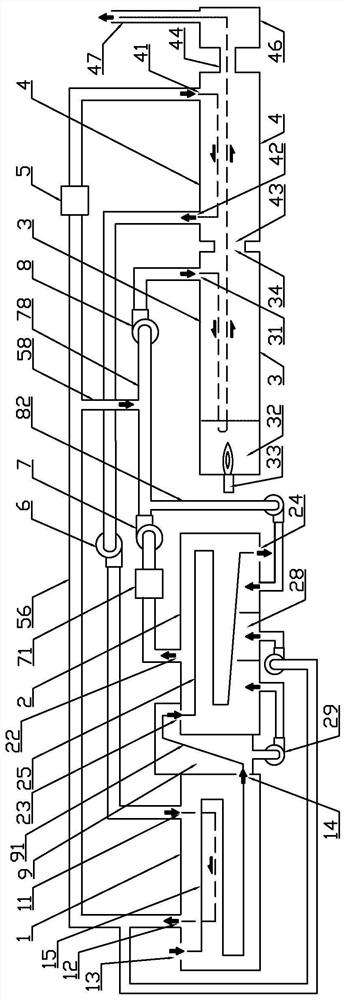

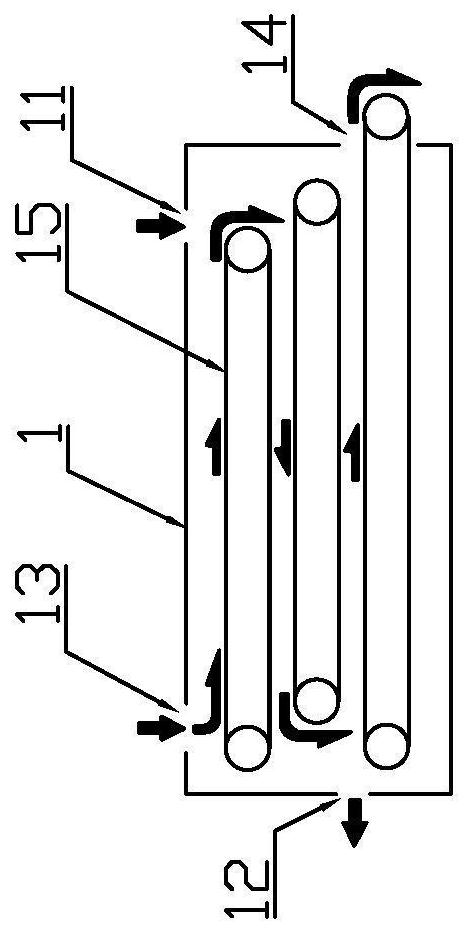

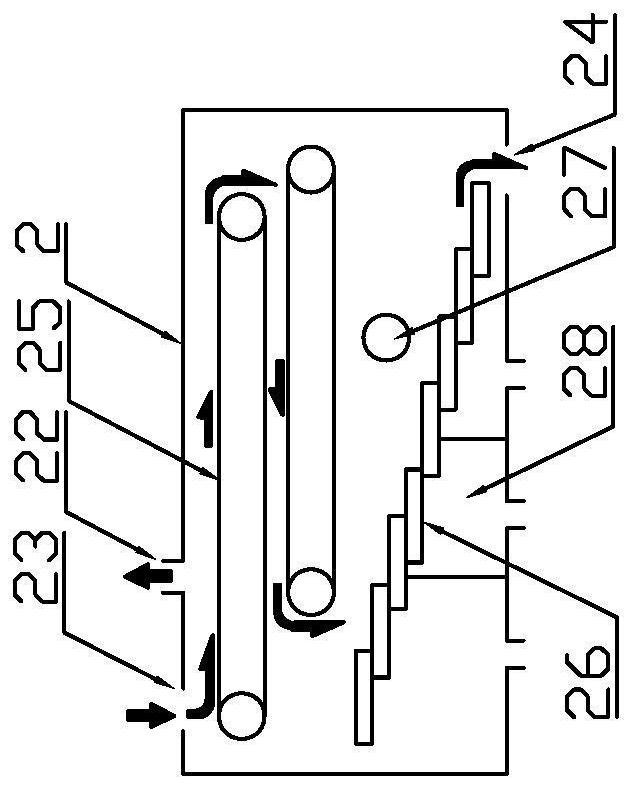

[0032] Embodiment 1: as Figure 1 to Figure 4As shown, a closed negative pressure solid waste oxygen control pyrolysis device includes a dryer 1, a pyrolysis burner 2, a low calorific value gas burner 3, a flue gas heat exchanger 4, a condensation dehumidifier 5, and a hot air circulation Fan 6, pyrolysis gas exhaust fan 7 and main fan 8, described dryer 1 is provided with material inlet 13, material outlet 14, hot air inlet 11 and moisture outlet 12, and described pyrolysis burner 2 is provided with There is a material inlet 23, a slag outlet 24 and a pyrolysis gas outlet 22, the low calorific value gas burner 3 is provided with an air inlet 31 and a flue gas outlet 34, and the flue gas heat exchanger 4 is provided with a flue gas inlet 43. Tail gas outlet 44, hot air outlet 42, and circulation return air outlet 41, flue gas inlet 43, and tail gas outlet 44 are respectively connected to the inlet and outlet of the first heat exchange channel of the flue gas heat exchanger, ho...

Embodiment 2

[0059] Embodiment 2: (as figure 1 , figure 2 , Figure 4 , Figure 5 ) A closed negative pressure oxygen-controlled pyrolysis device for solid waste, including a dryer 1, a pyrolysis burner 2, a low calorific value gas burner 3, a flue gas heat exchanger 4, a condensation dehumidifier 5, and a hot air circulation fan 6 , pyrolysis gas exhaust fan 7 and main blower 8, described dryer 1 is provided with material inlet 13, material outlet 14, hot air inlet 11 and moisture outlet 12, and described pyrolysis burner 2 is provided with material Inlet 23, slag outlet 24 and pyrolysis gas outlet 22, described low calorific value gas burner 3 is provided with air inlet 31 and flue gas outlet 34, described flue gas heat exchanger 4 is provided with flue gas inlet 43, Exhaust gas outlet 44, hot air outlet 42, and circulating air return port 41; flue gas inlet 43, exhaust gas outlet 44 are respectively connected to the inlet and outlet of the first heat exchange pipe of the flue gas he...

Embodiment 3

[0071] Embodiment 3: (as figure 2 , image 3 , Figure 4 , Figure 6 ) A closed negative pressure oxygen-controlled pyrolysis device for solid waste, including a dryer 1, a pyrolysis burner 2, a low calorific value gas burner 3, a flue gas heat exchanger 4, a condensation dehumidifier 5, and a hot air circulation fan 6 , pyrolysis gas exhaust fan 7 and main blower 8, described dryer 1 is provided with material inlet 13, material outlet 14, hot air inlet 11 and moisture outlet 12, and described pyrolysis burner 2 is provided with material Inlet 23, slag outlet 24 and pyrolysis gas outlet 22, described low calorific value gas burner 3 is provided with air inlet 31 and flue gas outlet 34, described flue gas heat exchanger 4 is provided with flue gas inlet 43, Exhaust gas outlet 44, hot air outlet 42 and circulating air return port 41; flue gas inlet 43 and exhaust gas outlet 44 respectively correspond to the inlet and outlet of the first heat exchange channel connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com