Guide blade type high-pressure cyclone separator

A cyclone separator and vane-type technology, which is applied in the field of vane-type high-pressure cyclone separators, can solve the problems of less particle back-mixing, suspended stagnant airflow, poor effect, and no extension of insertion depth, etc., to achieve significant separation effect, constant pressure drop, ideal separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0041] In conjunction with the accompanying drawings.

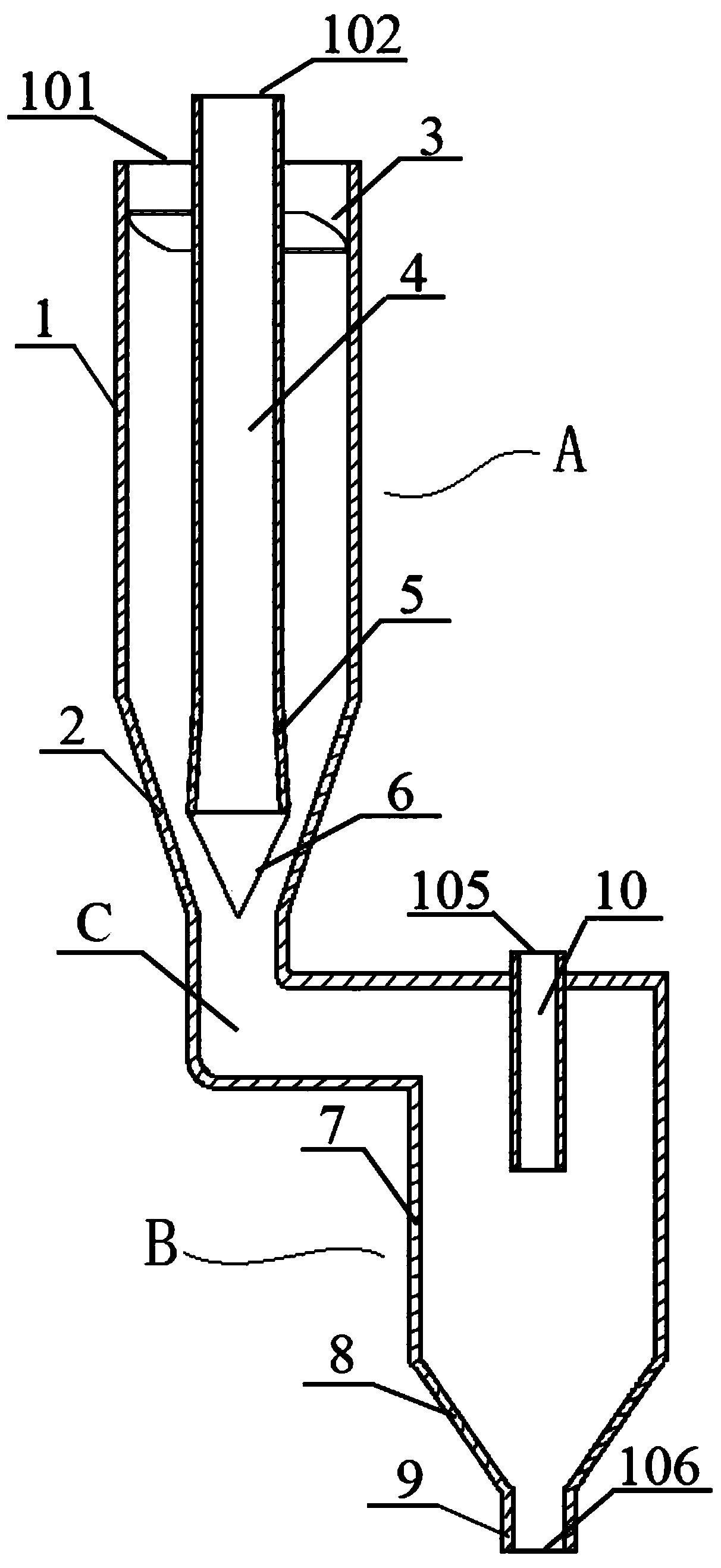

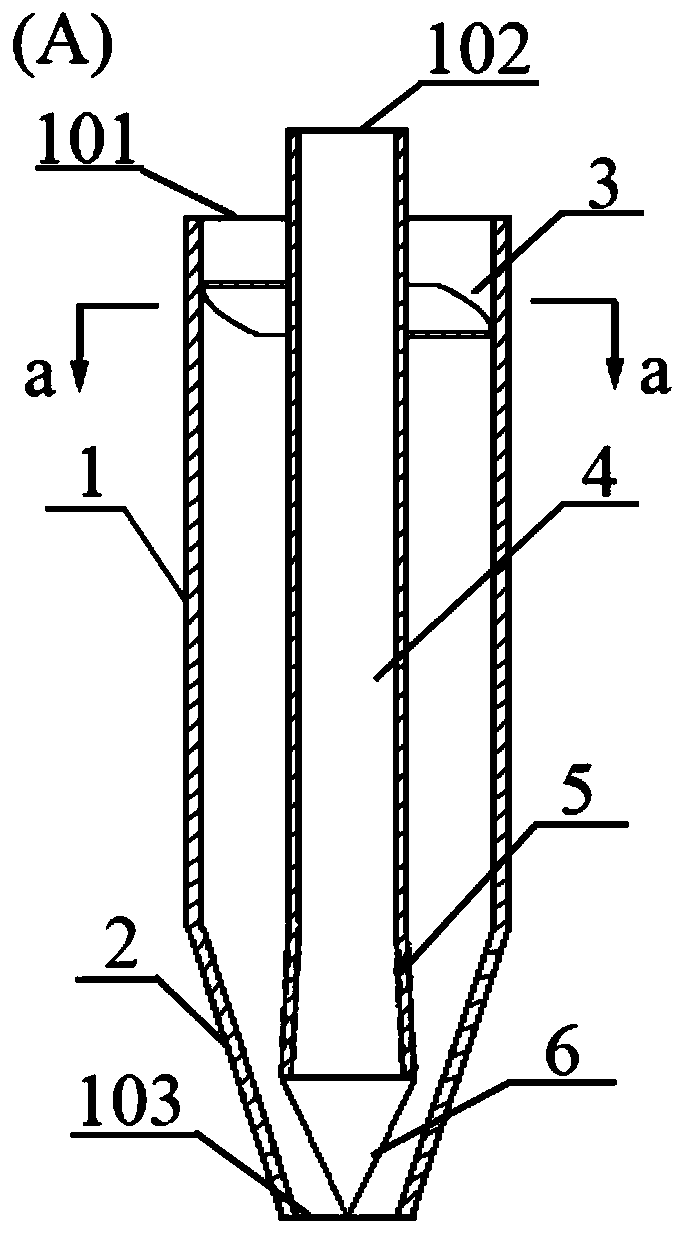

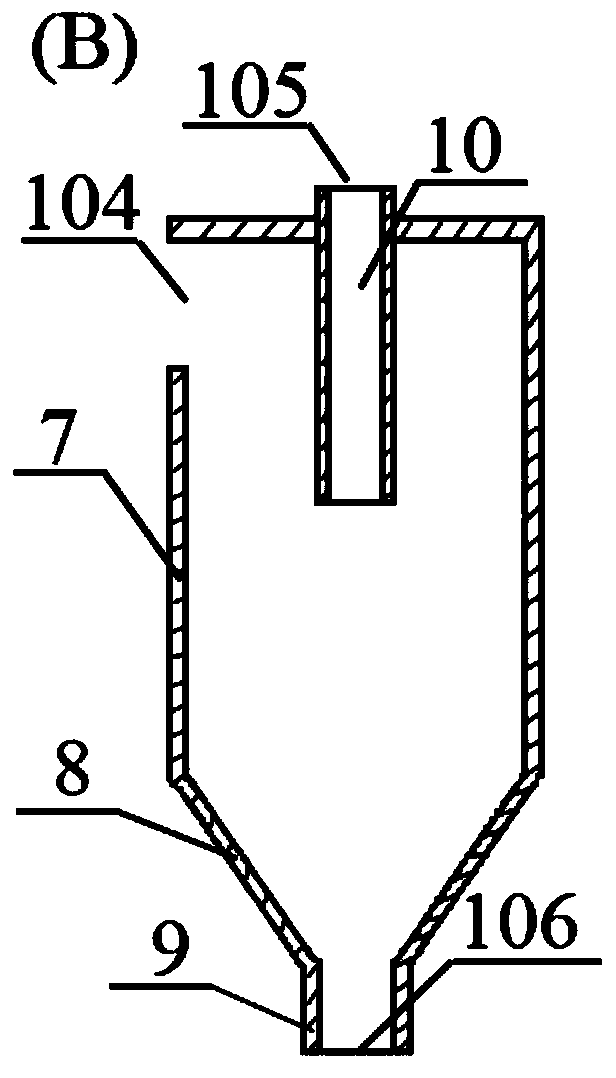

[0042] In this example, the vane-type high-pressure cyclone separator with the function of diversion and filtration includes separation unit A, secondary separation unit B and connecting elbow C; separation unit A includes an upper cylindrical cylinder 1, a lower cone 2, a diversion unit Blade 3, exhaust pipe 4, filter member 5 and guide cone 6; secondary separation unit B includes cylindrical shell 7, conical hopper 8, dust discharge pipe 9 and secondary exhaust pipe 10; the connecting bend in this example The angle of tube C is 90°~120°.

[0043]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com