Machining device and method of kidney-shaped half pipe

A processing device and processing method technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of reference offset, repeated positioning error, etc., achieve the effects of preventing deformation, improving processing accuracy, and avoiding repeated positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

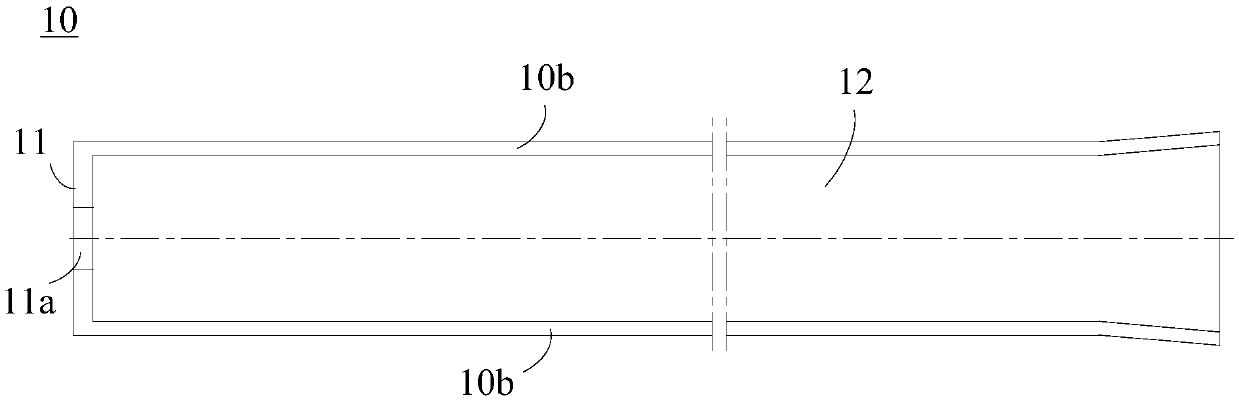

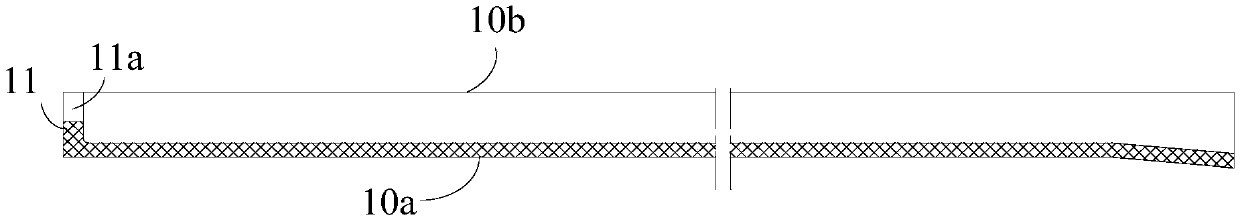

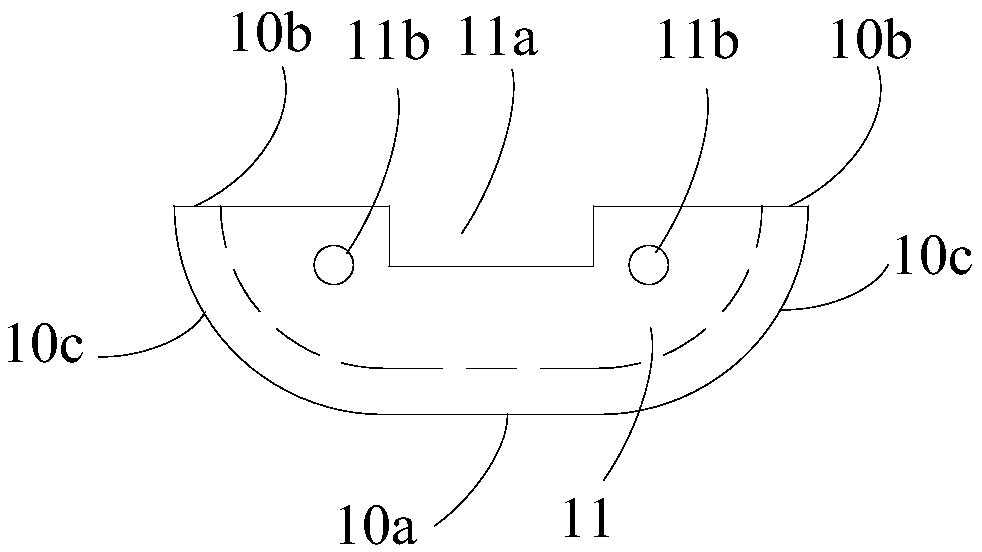

[0048] figure 1 A top view of a waist-round half-pipe. figure 2 Yes figure 1 cross-sectional view. image 3 Yes figure 1 left view of . Figure 1~3 A girdle half-pipe structure is shown. combine Figure 1~3 As shown, the waist pipe 10 includes a pipe body 12 and an end plate 11 located at one end of the pipe body 12 . The tube body 12 is in a semi-tubular shape, and the cross section of the tube body 12 is a figure obtained by dividing the waist circle into two along the long axis of the waist circle. The pipe body 12 has a lower bottom surface 10a, two upper bottom surfaces 10b, and two arc outer walls 10c connecting the lower bottom surface 10a and the two upper bottom surfaces 10b. The end plate 11 is provided with an end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com