Machining method for ensuring coaxiality of spacing ring part

A processing method and technology of coaxiality, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems such as the inability to guarantee the quality of mass-produced parts, affecting the production nodes of diesel engines, and the failure of normal production of parts, etc. High-precision coaxiality requirements, avoiding repeated positioning errors, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

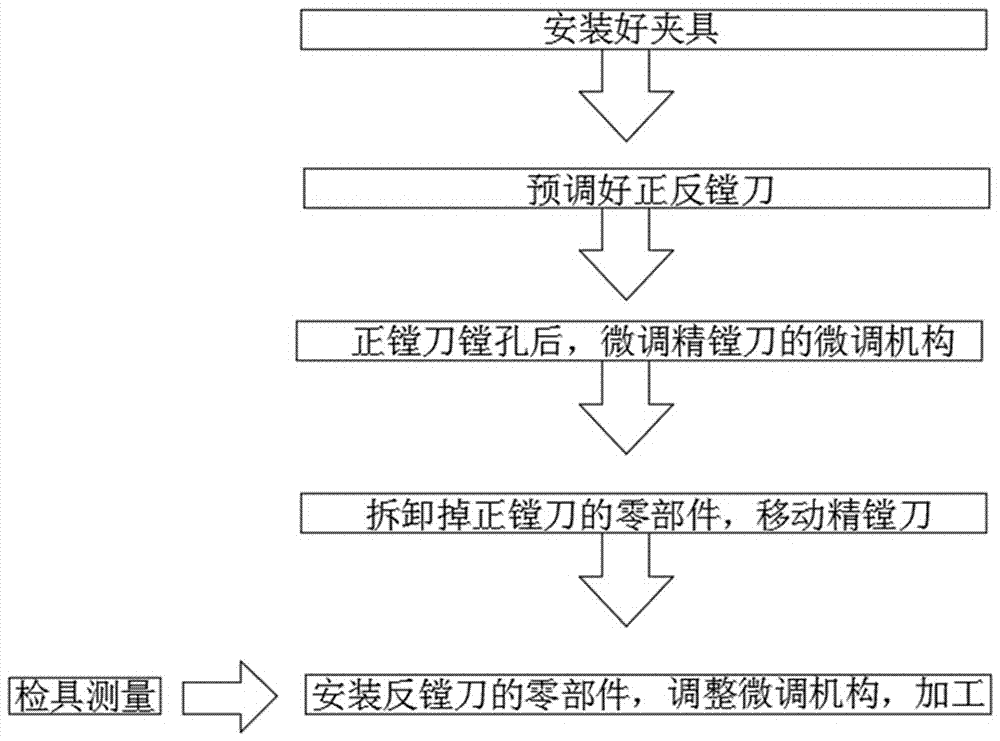

[0031] see Figure 1-6 As shown, a processing method to ensure the coaxiality of spacer parts includes the following steps:

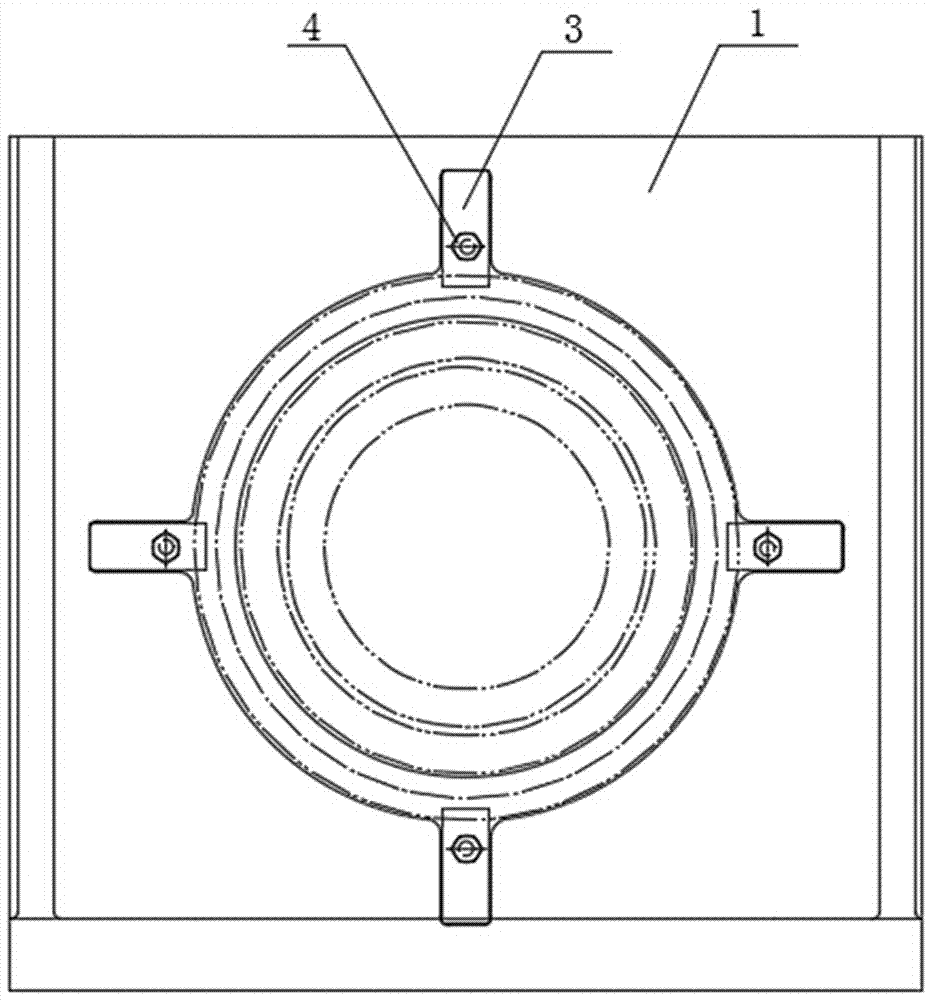

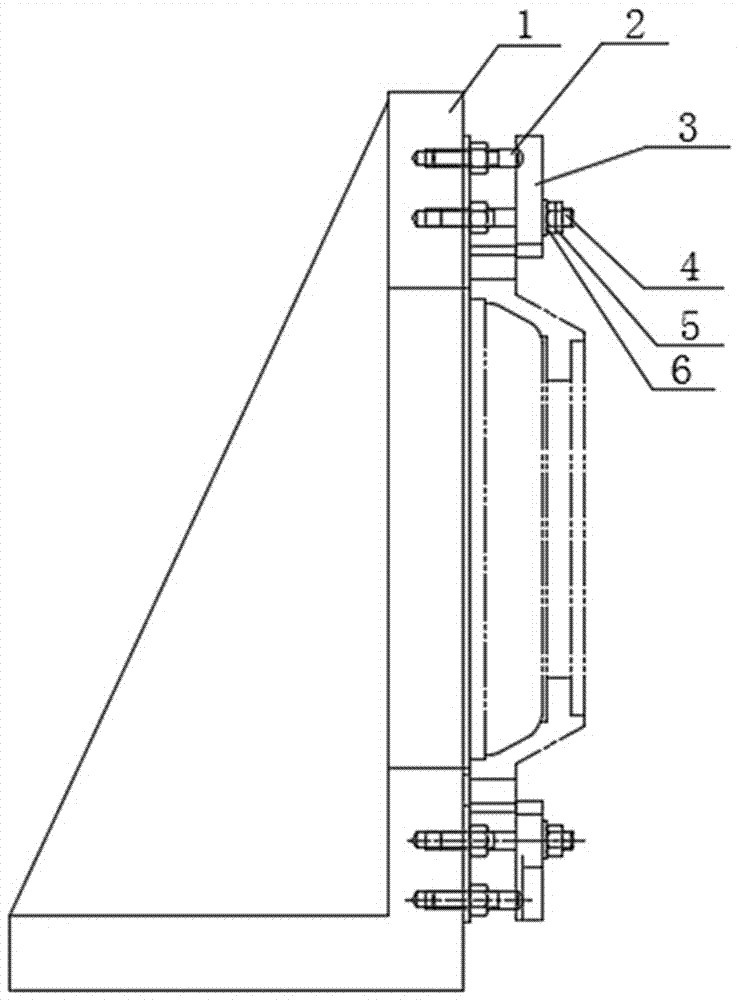

[0032] Step 1: Install fixture A on the boring machine workbench, press fixture A after correct positioning, and then install the workpiece on fixture A and press it with a pressure plate; fixture A includes angle iron 1 for connecting the spacer and the machine tool , the lower plane of the angle iron 1 is connected and fixed to the boring machine table, the spacer is fixed on the side of the angle iron 1 for positioning, and the spacer is fixed with four pressure plates 3, and the pressure plate 3 adopts four supports 2 for support, Four stud bolts 4 and four compression nuts 5 are used to compress the pressure plate and the spacer ring. The function of the fastening nut 8 is to fix the support 2 and the stud bolt 4 on the angle iron 1; There is a large hole in the middle of the angle iron 1, and the tool can pass through the back boring hole from th...

Embodiment 2

[0038] During back-boring processing, because the boring bar is in the hole, ordinary inner micrometers and inner micrometers cannot be used for measurement, and only special measuring tools and inspection tools D can be used for measurement; when machining larger holes, because the boring tool cannot be used in the hole Exit, the conventional inner diameter micrometer or dial gauge interferes with the boring tool when measuring the inner diameter size, and cannot measure the size of the trial machining hole. Use the inspection tool D that can cross the boring tool to measure the hole diameter, so as to adjust the fine boring head to meet the processing requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com