A multi-spindle multi-station connecting rod flexible processing equipment

A flexible processing and multi-station technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low degree of automation and flexible production, and achieve the avoidance of repeated positioning errors, easy reorganization, and simplified processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The above solution will be further described below in conjunction with specific embodiments.

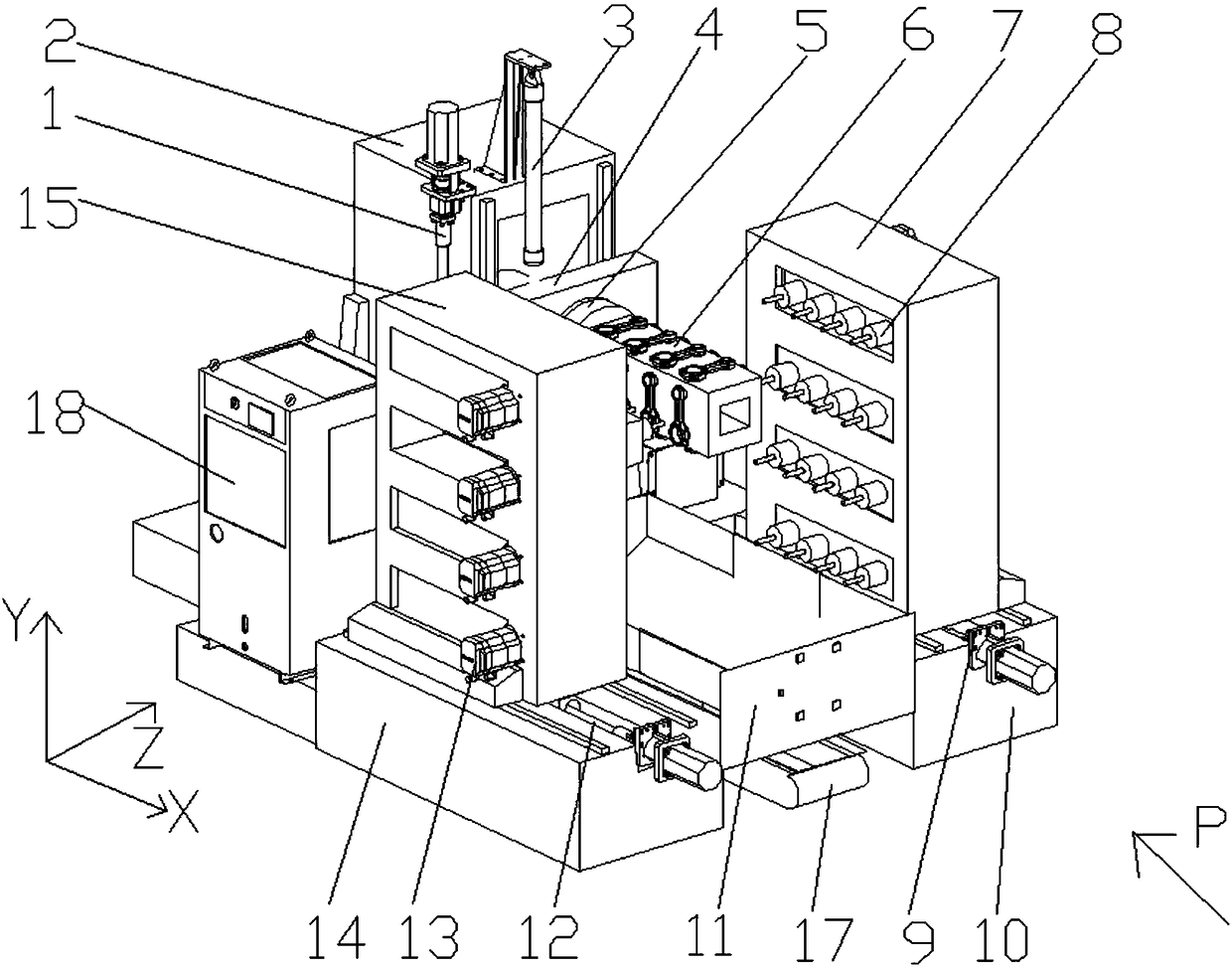

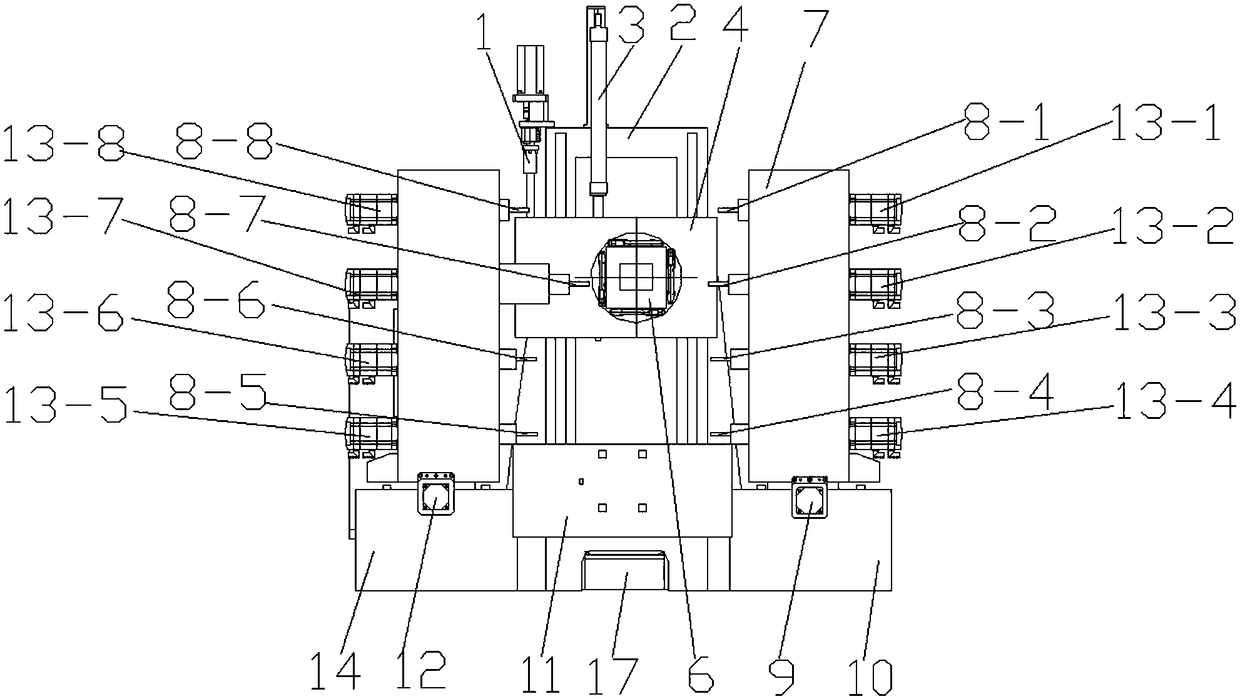

[0028] Such as figure 1 with figure 2 As shown, a multi-spindle and multi-station connecting rod flexible processing equipment includes X-axis feed drive system 9, Y-axis feed drive system 1, Z-axis feed drive system 13, and the overall machine structure layout is a stable ㄇ type , The X-axis bed 10 is set on the side of the Y-axis column and the bed 2; the X-axis spindle box 7 is installed on the X-axis bed 10, and is driven by the X-axis feed drive system 9; balance device 3 Installed on Y-axis column and bed 2 and connected with Y-axis ram 4; Y-axis ram 4 is installed on Y-axis column and bed 2 through Y-axis feed drive system 1; with hydraulic clamp The rotary table 6 is installed on the Y-axis ram 4 through the A-axis rotary head 5, and is driven by the A-axis rotary head 5 to realize the rotation and transformation of the rotary table 6 with hydraulic fixtures; the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com