An electrophoresis-assisted micro-ultrasonic processing machine tool and processing method

An ultra-sonic machining, micro-technology, applied in the field of machine tools, can solve the problems that it is difficult to ensure the verticality and coaxiality of the tool electrode, and affect the efficiency of micro-ultrasonic machining, so as to avoid repeated positioning errors, ensure the existence of abrasive particles, and improve the utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

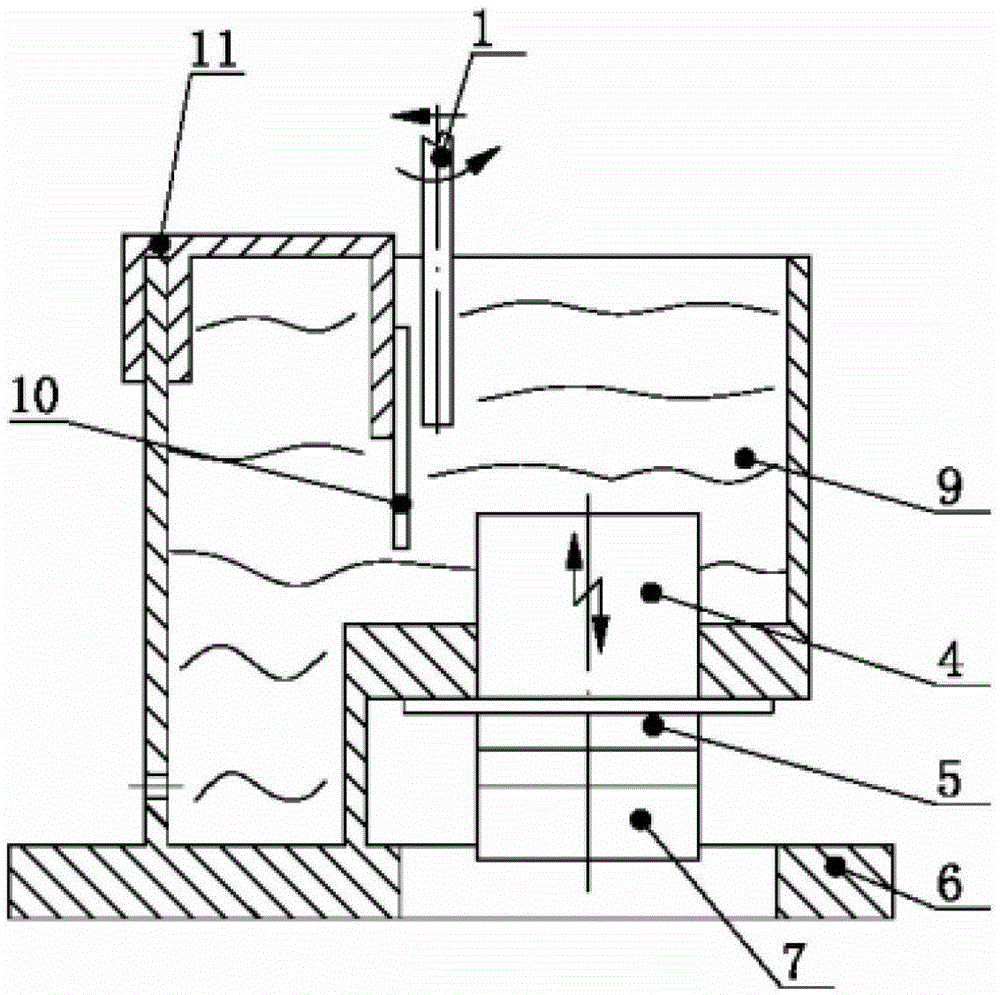

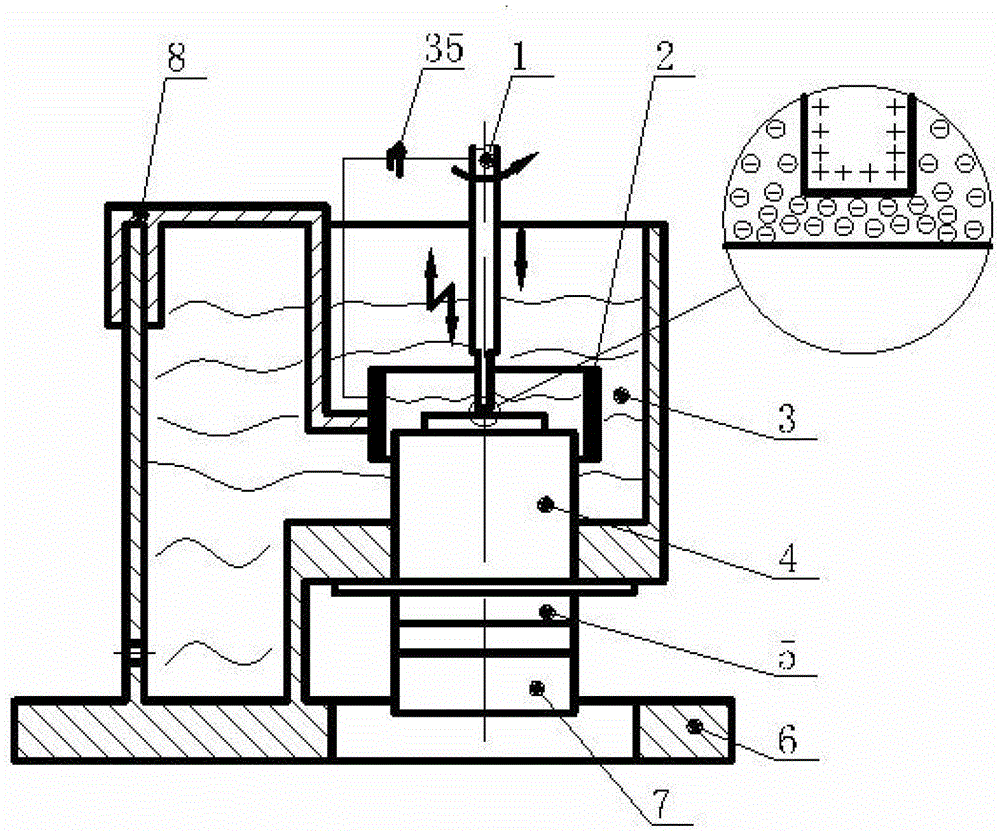

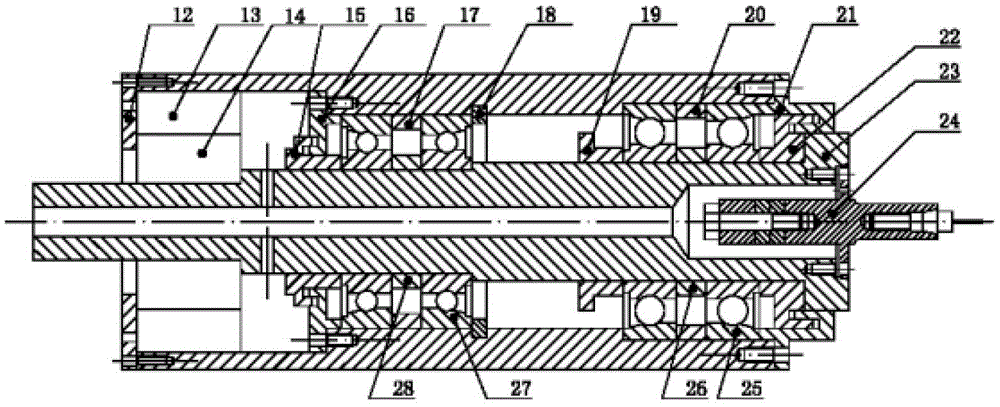

[0028] Such as Figure 1-5 As shown, a machine tool for electrophoresis-assisted micro-ultrasonic machining includes a spindle system, a power supply system, a spindle micro-ultrasonic longitudinal vibration system 24, an electrophoresis power supply 35, and a multifunctional cup-shaped working fluid tank 6; the spindle system includes a spindle 23 , the main shaft support assembly and the main shaft sealing assembly, one end of the main shaft 23 is connected to the servo motor through the slip ring inner ring 14, and the other end is connected to the nodal surface of the main shaft micro ultrasonic longitudinal vibration system 24; the power feeding system includes three leads , two of which are used to connect to the spindle micro-ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com